inventor sheet metal flange About Flanges in Sheet Metal. A flange feature consists of a face and bend . A wire running through the box counts as one wire. Each wire coming into a splice connector is counted as one wire. Each wire connecting to a device counts as one wire of that size. When devices are mounted in the box, the total conductor count must be increased by two for each mounting strap. NEC Table 370-16 Electrical Box Fill

0 · sheet metal flange diagram

1 · inventor sheet metal flange diagram

2 · inventor 2022 flange

3 · flanges in sheet metal

4 · create sheet metal flange

5 · autodesk sheet metal flanges

6 · autocad sheet metal flange style

7 · autocad sheet metal flange dimensions

Clear, easy-to-read wiring diagrams for connecting multiple receptacle outlets in a row, including GFCI and Duplex Receptacles.

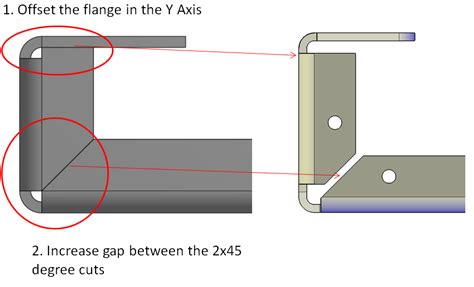

You can add a sheet metal face and bend connected to an existing sheet metal face with an angle that matches your selection. When you create the flange, the flange previews along the edge .About Flanges in Sheet Metal. A flange feature consists of a face and bend .Create flanges on your sheet metal part using the exact measurements your .Inventor does allow users to change the profile of the flange. It is always in one .

About Flanges in Sheet Metal. A flange feature consists of a face and bend connected to an existing face along a straight edge. To add a flange feature, you select one or more edges, and specify the size and position of the material .Create flanges on your sheet metal part using the exact measurements your assembly needs.

1. To set the parameters, click Sheet Metal > Setup > Sheet Metal Defaults on the ribbon; the Sheet Metal Defaults dialog appears. This dialog displays the default preferences of the sheet . Inventor does allow users to change the profile of the flange. It is always in one direction and uniform distance. It looks like you want to extend . The sheet metal flange feature consists of a face and bend connected to an existing face along a straight age. Hi. I am messing around with a part at the moment so if I was to put it up as an .ipt file it would be crucified for not being constrained, dimensioned etc etc. I am stumped I have to say. I am trying to get a 25 and 20mm return fold .

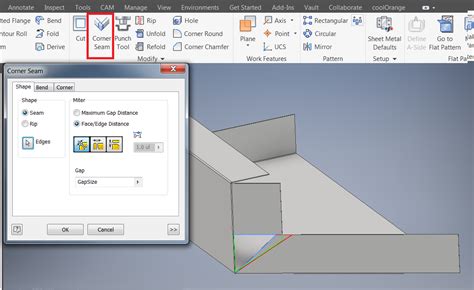

Hi there, I'm Les and I'm new to Autodesk Inventor and also this forum, so please bare with me. I drawing up a ceiling luminaire body and would like to work out how to edit the shape of the flange. I want to extend the edges . But I have the (3) flanges, 2 on the sides and a long one in the back. Then added corner seams between the long and sides to set and equal gap, but this pulls the corner style from the sheet metal defaults. With the hem . Your part has a curve, which the flange follows. Inventor sheet metal does not support that. In other words, your part may need to be a die formed part, not a press brake formed part. However, you can model any type of part in Inventor, but to get a proper flat pattern out means no non-linear deformation in sheet metal mode. . In this video Pete will demonstrate a technique for creating a flange overlap feature, or a jog feature, that can be very useful for fastening large sheet me.

I am using Inventor 2010. I have a sheet metal box where I created the 4 outer flanges in the same flange feature because they were all going to be the same length. Now because of a design change, I need to delete one of those edge flanges leaving just 3. These flanges have holes in them. What is the best way to do this without deleting the entire feature .

sheet metal flange diagram

inventor sheet metal flange diagram

Part 2: Autodesk Inventor Basics 438 2. Click Finish Sketch. 3. To create the base component, click Sheet Metal > Create > Face on the ribbon; the Face dialog appears. 4. Click OK to create the tab feature. Creating the flange 1. To create the flange, click Sheet Metal > Create > Flange on the ribbon; the Flange dialog appears. Building "thin" sheet metal features with Inventor's Contour Flanges

A single flange or contour flange feature in a sheet metal part can contain any number of bends. You can override default sheet metal styles from the Bend dialog box as you create your sheet metal bend. These settings include how the flat pattern unfolds, and the .

Inventor iLogic, Macros, AddIns & Apprentice Forum. Share your knowledge, ask questions, and explore popular Inventor topics related to programming, creating add-ins, macros, working with the API or creating iLogic tools. . Modify Sheet metal flange position with iLogic Is it possible to access a flange feature by its name and modify the bend . Could anyone help please, I'm using Inventor 2008 Pro in the sheet metal format, and having a slight problem with corners!! The guys in the workshop are telling me that when they bend up an enclosure the edges of the flanges are always corner to corner. I've been trying to achieve this by creatin. Sheet metal flange interference So I'm trying to create multiple flanges on an odd angled part of sheetmetal. . All the solutions means extra features to make and adding material if you add the flange on the outside inventor does, so Inventor should remove materiaal if there is interference.. Reply. Reply. 0 Likes 07-05-2021 01:08 AM. Hi All,

Inventor Forum > Sheet metal flange with arc; Inventor. Community Forums; Inventor Forum . Sheet metal flange with arc Being quite new to Inventor I am trying to make a bracket, almost identical to the one in the video url however I need the (top) flange with the slot that runs from left post to the right post in a arc instead of flat. .Learn inventor sheet metal basic tutorial how to use lofted flange with 2 profile, check it out!!!#sheetmetal #inventor #modeling Hey Guys, First time posting on this forum, I have searched through existing posts which have helped to an extent however I'm still looking for a way to solve this issue. I have attached a quick part file I did to demonstrate what .

I guess I did not explain the behavior clearly. Although Flange and Extrude look similar, the concept is quite different. Extrude can terminate to any shape, as long as the end cap leads to a valid body. Flange on the other hand . Learn autodesk Inventor sheet metal tutorial how to use contour flange to create plate from sketch, check it out!!!Don't forget guys, if you like our videos . I'm using Inventor 2016 Pro. I thought I was able to do this in previous versions, but searching here it seems to be a long standing issue, so maybe not. When I go to make a flange, I select the edge and choose "to" under height extents..but then it won't let me select any faces or planes. Isn't that the point of using the "to" option?

Hi! I took a quick look at the part. The flange fails to create at the cut edge is because the side face is not perpendicular to the sheet metal face. As a result, the thickness is inconsistent with the sheet metal thickness. There are two ways to solve the problem. 1) Edit the Cut feature and check Cut Normal option. Sheet Metal: Flange Creation failed.Not a valid sheet metal edge: adjacent face thickness may be different from sheet metal settings. Somehow I can't form a flange at just this particular edge, though I can form a flange just about anywhere else. . Welcome to Autodesk’s Inventor Forums. Share your knowledge, ask questions, and explore . Autodesk Inventor 2012 Sheet Metal Flange offset, how to use one flange command and create two different flange offsets. Solved: Hello, I am still learning Inventor. How do i close the gap at the corners of a sheet metal box? Inventor 2015. Thank you. Forums Home > Inventor Community > Inventor Forum > how to close gap at corner; Inventor. Community Forums; . For starters, when you do a flange, your bend position matters. Then under the corner tab, you can .

Use sheet metal tools to create your sheet metal part (not Extrude). Cut is on the sheet metal tab. Once you get into the command you will see the Across Bend option. Information on using tool can be found in the wikiHelp. I am using a later version of Inventor - so posting an example won't help.

Hi All, I need a quick lesson on how to manipulate this flange. I am not a sheet metal guy so I rely on Inventor to to the bending for me. In the attached pan, I made a cut at one corner. However, I want the flange that remains complete to extent up to the same height as the adjacent flange but without the bend. I know Inventor has to have a way to create this geometry as a sheet metal part somehow - I'm pretty sure this is something I could have done in Creo with the extrude sheet metal wall command - but at this point my limited Inventor expertise has left me scratching my head, and all the tutorials I could find using the lofted flange didn't give . Hello Everyone, when creating flanges on my part (attached, IV2010), actually on all faces resulted from trimming, I am getting error: Sheet Metal: Flange Creation failed. Not a valid sheet metal edge: adjacent face thickness may be different from sheet metal settings. I think my procedure is quit. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

inventor 2022 flange

8 axis cnc milling machines

How to wire an electrical junction box. A junction box is used to add a spur or to extend circuits and direct power to lights and additional sockets. Advice on wiring electrical junction box with easy to follow junction box wiring diagrams, including information on 20 and 30 amp junction boxes.

inventor sheet metal flange|autocad sheet metal flange dimensions