introduction to cnc part programming SC ACCELERATE Open Text MTT 255 Module 1 Page | 6 Version │ Module 1 │ Rev 1 2012 SC ACCELERATE 1.2.1 WORD (X 5.00) The “Word System” controls the direction and length of movement when controlling a CNC machine tool. The “Word System” must have an “address” and “value” in place to function properly. An example of a

The medicine cabinet is made from iron with a white paint finish. It features a magnetic catch frosted glass hinge door with a locking mechanism and comes with two keys. The cabinet has four large fixed shelf units, each with a depth of 4.25 inches and a height of 5.15 inches. The content is visible through the frosted door.

0 · manual cnc programming for beginners

1 · different types of cnc programming

2 · cnc programming website

3 · cnc programming full form

4 · cnc programming and machining

5 · cnc machine programming and operation

6 · cnc lathe programming for beginners

7 · basic cnc programming for beginners

Providing Professional Heating, Cooling & Indoor Quality Services Since 1948. Winters Heating & Cooling is a family-owned and operated HVAC company, which has served Southern Maryland since 1948. Our 24-hour emergency service line is available to accept service inquiries and requests at any time.

In this series, we will take you on a journey from the fundamentals to mastering the art of CNC programming. We'll demystify the complexities, break down the technical jargon, .

Learn about CNC programming and improve your skills with CNCCookbook's articles, tips, and resources for beginners and experienced . CNC Part Programming Basics: A Video IntroductionThis video provides a beginner-friendly introduction to CNC part programming, the process of creating instru. Understand the basics of CNC programming with our step-by-step guide. Gain a solid foundation in CNC programming principles and techniques. Learn how to analyze part diagrams and calculate tool paths. Discover the .Explain what computer numerical control (CNC) is and what basic components comprise CNC systems. 2. State the objectives, advantages, and special requirements concerning CNC use. .

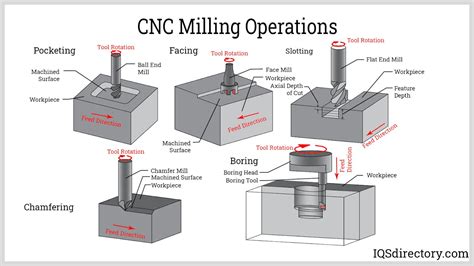

SC ACCELERATE Open Text MTT 255 Module 1 Page | 6 Version │ Module 1 │ Rev 1 2012 SC ACCELERATE 1.2.1 WORD (X 5.00) The “Word System” controls the direction and length of movement when controlling a CNC machine tool. The “Word System” must have an “address” and “value” in place to function properly. An example of aThe CNC Programming - Online Course Includes: . CNC Milling. Part Drawings, G-Code Information, Exercise Drawings and full Video Instructions covering: Absolute and Incremental Positioning; Introduction to CNC Codes; Creating CNC Programs; Drilling with Canned Cycles; Linear Interpolation; Circular Interpolation;

controlling the part programming, and • description of some common miscellaneous or M codes that are used in most of the CNC machine tools. 4.2 PART PROGRAMMING FUNDAMENTALS As discussed earlier, the numerical control machine tools require a part program to generate the requisite geometric shape of the components. The part program is basically aSpanish for Beginners Course Part 2; Certificate in British Sign Language (BSL) Level 1 & 2; Arabic Language Course – Hide; . To enrol in An Introduction to CNC Programming, participants should have a solid grasp of relevant subjects or disciplines and a strong interest in the field. This course is designed for recent graduates .

Study with Quizlet and memorize flashcards containing terms like Why were many companies slow to develop numerical control technology in the 1950s?, The development of the minicomputer converted numerical control technology to ______. A. punched paper tape B. automated numerical control C. computer numerical control D. programmed codes, A major .

requirement of skilled part programmer. ELEMENTS OF A CNC A CNC system consists of three basic components (Figure 2) : Part Program 1 . Part program 2 . Machine Control Unit (MCU) 3 . Machine tool (lathe, drill press, milling machine etc) The part program is a detailed set of commands to be followed by the machine tool. Eachare to program and edit part programs as well as download part programs to NC machines. Machine tool controllers have limited memory and a part program may contain few thousands of blocks. So the program is stored in a separate computer and sent directly to the machine, one block at a time. 10 DNC systems Introduction to CNC: Understand the basics of CNC machining, its applications, and its significance in modern manufacturing. CNC Machine Components: Explore the key components of CNC machines and their functions, from the controller to the cutting tools. G-code and M-code: Grasp the essential programming languages used in CNC machining.

Programming with Subprograms. Introduction to the CNC Lathe. Fundamental Concepts of CNC Lathe Programming. Techniques and Fixed Cycles for CNC Lathe Programming. Modern Computer-Aided Part Programming. Elements of the Computer-Controlled Factory. Appendices cover safety shop rules; G and M codes for Fanuc controllers; . Presents a balanced introduction to both machining and part programming. Uses the reader's knowledge on conventional machines to explain the operation of CNC machining. Includes sufficient information to provide the theoretical knowledge and practical aspects needed to comprehend CNC machining. This third edition of an award-winning classic in the field marks a breakthrough in technology-aided learning. Introduction to Computer Numerical Control (CNC), Third Edition, continues with its major goal of clearly presenting the fundamentals of CNC operations and programming. Also, with the addition of the Predator simulation software, readers will have an .ToolingU: Introduction to CNC Machines 201. 15 terms. Edwardsb2. Preview. Ecosystems Study Guide. Teacher 21 terms. dcarroll454. Preview. asdfasdfasf. 15 terms. Adolfo_Hatlero. . Part Program. A series of alphanumerical instructions used by a CNC machine to perform the necessary sequence of operations to machine a specific workpiece.

CNC Part Programming NC Coding and G-code. NC coding uses a common language; CNC languages are typically referred to as “G-code” Programmers must first establish a reference or zero point; The part is then programmed, defining each step necessary to produce the part; Following coding, the code is verified, typically by computer simulationIntroduction to CNC Programming Learn about programming format,G Code,M Code,Absolute & Incremental mode,Interpolation & many more. Updated on Sep, 2024 . And finally we will learn about the basics of CNC programming which will include programming format explaining different types of codes as such G code, M code, S,D,F and many more. .01 LP.1 Introduction to CNC Programming 02 LP.2 Manual Part Programming and Simulation of Turning Part Programs: Ex.01 & Ex.02 03 LP.3 Manual Part Programming and Simulation of Turning Part Programs: Ex.03 & Ex.04 04 LP.4 Manual Part Programming and Simulation of Turning Part Programs: Ex.05 & Ex.06 05 LP.5 Manual Part Programming andPresents a balanced introduction to both machining and part programming. Uses the reader's knowledge on conventional machines to explain the operation of CNC machining. Includes sufficient information to provide the theoretical knowledge and practical aspects needed to comprehend CNC machining. Contains a chapter on conversational and manual programming .

The process of programming CNC Parts involves transitioning from a Design to a G-Code Part Program. 1. Decide What Programming Tools to Use. Deliverable: Choose CAM, Conversational CNC, or Hand Written G-Code . – . 7. CNC Machine To overcome the shortcomings of the NC machines CNC machines evolved. CNC machines are the NC machines whose MCU is based on the micro computer rather than the hardwired controller. Elements of CNC machines are Part program Machine Control Unit Machine tool Features of CNC machines are: Storage of more than one .

Discover the applications of CNC in the metals industry. CNC programming is used by assemblers, fabricators, computer programmers, machinists, and industrial machinery mechanics to direct machines for producing parts. Explore G and M code programming and interface with auxiliary equipment. With the skills gained in this course, you will be able .CNC part programming is the art of creating instructions that tell the CNC machine how to move, position, and operate the cutting tools to produce the desired shape and dimensions. Programming for taper turning requires a solid understanding of G-code, which is a programming language used to control CNC machines.6.1 CNC PART PROGRAMMING L T P 3 - 2 RATIONALE Diploma holders are required to supervise and handle specialized machines and equipment like CNC machines. For this purpose, knowledge and skills about part . Introduction to Part Programming (6 hr s) Part Programming, definition and need, Basis concepts of part programming, Introduction to CNC Programming: CNC (Computer Numerical Control) machines have transformed the manufacturing industry by allowing precise control over machine tools through programming. . M-Code (or "Miscellaneous Code") is another critical part of CNC programming. While G-Code focuses on the tool’s movement and the geometry of machining .

Techniques and Fixed Cycles for CNC Lathe Programming. 17. Introduction to CNC Wire EDM. 18. Modern Computer-Aided Part Programming . Appendix H: Writing and Verifying Mill Part Programs via Predator Simulation Software. Appendix I: Running the Lathe Simulator. Appendix J: Writing and Verifying Turn Part Programs via Predator Simulation .

manual cnc programming for beginners

During this session about CNC lathe programming, Brian explained some of the main concepts, gave an overview of the most important G-codes and shows an example of how to program a single part. Here’s what you’ll learn during the session: 0:00 Introduction to CNC tool room lathe programming 5:36 Lathe specific G-codes and informationFig 1.5: Coordinate system of standard lathe 6 Fig 1.6: Standard CNC milling axis of motions Part Program: A part program is a set of instructions often referred to as blocks, each of which refers to a segment of the machining operation performed by the machine tool. Each block may contain several code words in sequence. These provide: 1.

1.1 Introduction to CNC Machining - Basic Mill Operator . The CNC machine was created to provide accurate production parts. What does CNC stand for? A. Computer Numbered . An important element of a CNC machine is that the parts made today, will be identical to the parts made yesterday, for any one program being run in the machine. About us .CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such as cutting, milling, and drilling. CNC programming involves writing a series of commands, typically in the form of a .

name support bracket metal

At Windowbox.com, we offer the widest selection of bracketry to fit railings of most every size to work with our window boxes and planters. Everything from wood rails to metal rails, round, square and rectangles, we have you covered.

introduction to cnc part programming|cnc machine programming and operation