junction box vs pull box A junction box contains two 3 inch raceways on the left side, one 3 inch raceway on the right side, and one 3 inch raceway on the bottom. The conductors from the lower 3 inch raceway on the .

Find something softer, like silicon bronze, as a filler material, which is also thinner than the base metal as well. Otherwise, you may not be able to do the joints properly due to overheating issues. If you prefer to have more .

0 · utility box junction and pull

1 · underground electrical pull box installation

2 · pull box electrical

3 · nec distance between pull boxes

4 · nec compliant junction boxes

5 · maximum distance between junction boxes

6 · electrical pull box size chart

7 · different types of pull boxes

Welding thin sheet metal is a challenge for any welder, but it can be even more daunting as an entry-level amateur or as a seasoned professional. For novices and experts alike, the key to successful welding of thin sheet metal is practice and patience.

Initial Purchase Costs. Essential junction boxes cost to , with specialty boxes reaching 0+. Pull boxes typically run higher, starting at and reaching 0+ for large . Learn the key differences between pull boxes and junction boxes, their functions, and when to use each in electrical installations for safety and . You must size pull boxes, junction boxes, and conduit bodies large enough so a crew can install the conductors without damaging them. For .Pull and junction boxes As a rule of thumb, pull boxes are used when conductors are pulled straight through a box and terminated down-stream. On the other hand, junction boxes can be .

The pull box provides another lubrication point, plus it allows you to reduce the force needed to pull that run in the first place. For straight pulls, 314.28(A)(1) requires that the length of the box be at least eight times the .

A junction box contains two 3 inch raceways on the left side, one 3 inch raceway on the right side, and one 3 inch raceway on the bottom. The conductors from the lower 3 inch raceway on the . 4awg wire is good for 85 amps but can be protected at 90 since they do not make an 85 amp breaker. You can use conduit bodies as a pull but they are not going to be large enough for a splice, the pull box size will be .

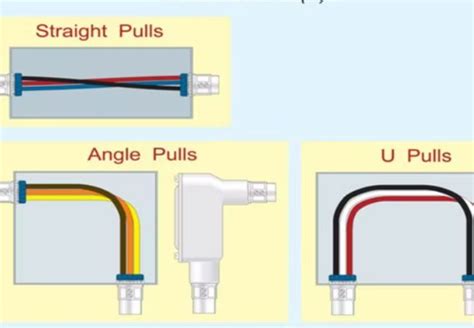

If I nipple the 4- 31/2" conduits into the switch is the box a pull box which would ned to be sized in accordance with 314.28, or is it an auxiliary gutter. My contention is that if the bottom of the box does not open into the top of the ATS, it's a pull box and if the bottom of the box and top of ATS enclosure are open, it's an auxiliary gutter.A junction box is always a pull box, but a pull box isn’t always a junction box. I mainly use pull box for feeder raceways as there shouldn’t be junctions, but call branch circuit raceways junction boxes as it’s common to split off from them. In reality it doesn’t matter, they are both boxes and installing an 8x8x4 pull box is no .Discover the key differences between junction box vs pull box in electrical installations. Learn which one fits your specific needs. Clear technical distinctions exist between junction boxes and pull boxes in electrical systems. These differences affect their applications, installation requirements, and overall project costs. the pull box and junction boxes are sized the same way. (2) Angle or U Pulls, or Splices. Where splices or where angle or U pulls are made, the distance between each raceway entry inside the box or conduit body and the opposite wall of the box or conduit body shall not be less than six times the metric designator (trade size) of the largest raceway

utility box junction and pull

I fail to see the charm. Last time I compared my everyday 4x4x1-1/2" drawn steel box (99 cents normally) or Handy-Box same price. vs the blue plastic boxes (99 cents normally) and the orange "wish" boxes I failed to grasp the cost benefit of plastic. (don't blame plastic for "shortage pricing").In my area use of junction boxes is only allowed in unique circumstances where there's some reason you can't put a manhole. The most recent example I've come across was a situation where we had to make a connection between two storm sewer systems directly underneath the mainlanes of an interstate, and you wouldn't want a manhole popping up in . I know many people tend to confuse electrical terminal box and junction box. Well, this guide will help you understand what these two essential accessories in electrical installations are. From definition, uses, installation, uses to features – we will explore every aspect of terminal box vs junction box. Let’s dive [.]

See relevant content for bcsboxer.com. Please turn off your ad blocker.Conduit Junction Box vs. Pull Box. Conduit junction boxes and pull boxes serve different purposes but are sometimes confused due to their similar appearances. Here’s a quick comparison: Conduit Junction Box: Used to enclose electrical connections and protect them from environmental factors, tampering, and accidental damage. They are essential . Looking for a little code info on trough vs large j boxes. Concerning use above or below panels. I know it has to do with the number of wires in a cross sectional area. Looking for the code redrence and year. . You'll want to look at article 376 for your trough information and article 312 for pull boxes/ junction boxes. Replies based on NEC 2014.Discover the essential role of pull boxes in electrical installations, ensuring safety and efficiency. Learn about the types, components, and benefits of pull boxes, along with guidelines for proper installation and maintenance. Enhance your understanding of how these enclosures facilitate wire pulling, splicing, and maintenance, contributing to the longevity and reliability of electrical .

Sizing Tips for Pull Boxes and Junction Boxes. When sizing pull boxes and junction boxes, follow these suggestions: Step 1: Organize and always draw out the problem. Step 2: Calculate the horizontal distance(s): • Left to right straight calculation • Right to left straight calculation • Left to right angle or U pull calculation

The following article is designed to help you understand what factors to consider in choosing the proper traffic rating for pull boxes and covers. Should you have any questions, please call our experts at 800-767-1576, contact us or view traffic rated pull box products for information on each specific enclosure.

It's your choice whether to snake one run of cable or use junction boxes. But you need to have a junction box large enough to take the incoming power cable, a receptacle unit, and two or three branches continuing on. Also, if you use one of the receptacle boxes as a junction box, you need to be sure the box is big enough for the incoming cable . Does the NEC allow an existing junction box to be used as a pull box for new wire/cable without the box being sized correctly. What are the NEC rules?[/ quote] A code forum, and inserting this phrase in the question does not lead to the most friendly of responses. The NEC rules are.size the box correctly.

infinity roofing and sheet metal

Junction box - where wires are spliced together or where conduits meet (wires don't necessarily need to be spliced in it. Distribution box - another term for panel board, electrical panel, fuse box, etc Terminal box - the box mounted on /in a .the second major differentiator between plastic and metal boxes as far as switches and Outlets are concerned is that plastic boxes have a 2 inch by 4 in footprint, which quite frankly is a little bit easier to work with for tucking the wires in whereas gangable metal wall case boxes are 2x3 footprint and you have to compensate with more depth .Experience Junction box vs pull box, Pull and Junction Boxes and Conduit Bodies. Angle Pulls, U .

industrial metal fabrication inc newton ks

Video covering general requirements for pull and junction boxes as well as how to size them. Metal boxes are usually made of aluminum, steel or cast iron. The boxes made without metal are PVC or plastic. Metal Boxes: Many local building codes require metal junction boxes because they are durable and ensure long-lasting performance. Choose from many junction box sizes to find the one that best suits your project.Pull Box คือ กล่องดึงสายไฟ Junction Box คือ กล่องต่อแยกสายไฟ หรือกล่องพักสายไฟ แล้วในรูปเป็นกล่องอะไรนะ (Wall Box)

We always use a pull box for this application. The C condulets have come in handy for 3/4" and 1" runs that exceed the maximun pull distance. This way we can pull straight through it and not waste time with splice or installing a 4 square box. The 4 square box has to be supported while the condulet does not. No, the graphic refers to one specific wireway rule (376.23(B)) that says in the situation described therein, you have to follow one particular pull box rule (314.28(A)(1) or 314.28(A)(2)). But it doesn't say, nor is it true, that a wireway used as a pull box must comply with all the pull box rules. Cheers, Wayne 312.8 Enclosures for Switches or Overcurrent Devices. Enclosures for switches or overcurrent devices shall not be used as junction boxes, auxiliary gutters, or raceways for Junction box = box with no components mounted in it (i.e. all connections are wirenuts or split bolts). Most conductors are long enough to be pulled from the box (i.e. the 6" length required at devices) Terminal box = box with components (i.e. terminal strips) mounted in it. Most conductors are trimmed to length to fit into terminal (like in a .

It is basically an enclosure designed for a specific purpose, most are built to same base specs as a pull/junction box but have provisions to mount specific equipment inside and likely have somewhat unique doors/trims compared to a general use pull/junction box to go with what is mounted inside.

underground electrical pull box installation

pull box electrical

- Fits E&C L96 (EC501) - Also fits WELL MB01, 05, 06, and 08 series. Should fit anything made for AW338 or Type96 series in general. - Full metal construction

junction box vs pull box|pull box electrical