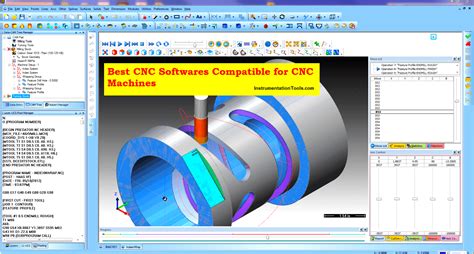

cnc machine program What is CNC Software? “CNC programming software (Computer Numerical Control Software) is software that allows mobile devices such as a computer to communicate with CNC machine tools like lathes, saws, plasma cutters, mills, etc.” Rather than having a human operator perform each task, CNC software essentially assists in the cutting and shaping. The machines of the AC-1 series are highly flexible and predestined for the complete .

0 · top 10 cnc programming software

1 · different types of cnc programming

2 · cnc programming website

3 · cnc programming for dummies

4 · cnc milling programming for beginners

5 · cnc machine programming and operation

6 · cnc lathe programming for beginners

7 · basic cnc programming for freshers

Below you will find a chart for metal thicknesses and weights. Commonly used metals for manufacturing at our shop are: Aluminum: 0.025", 0.032", 0.040", 0.050", 0.063", 0.080", 1/8" (0.125") and 1/4" (0.25"). Cold and hot rolled steel: 16 gauge, 14 gauge, 1/8" and 1/4". Galvanized steel: 24 gauge, 20 gauge, 18 gauge and 16 gauge.

top 10 cnc programming software

cheap cnc precision parts

different types of cnc programming

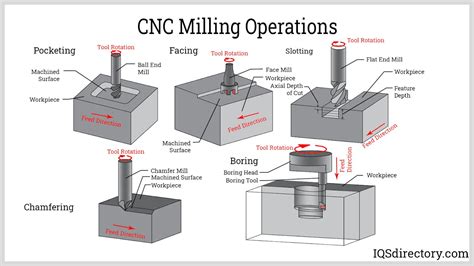

CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC .CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such . CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC milling machines, CNC lathes , and 3D printers.

Understand the basics of CNC programming with our step-by-step guide. Gain a solid foundation in CNC programming principles and techniques. Learn how to analyze part diagrams and calculate tool paths. Discover the difference between manual and automatic CNC programming. Explore popular CNC programming software used by professionals. What is CNC Software? “CNC programming software (Computer Numerical Control Software) is software that allows mobile devices such as a computer to communicate with CNC machine tools like lathes, saws, plasma cutters, mills, etc.” Rather than having a human operator perform each task, CNC software essentially assists in the cutting and shaping.Fusion is CAM software that can create high-quality CNC machining code for many types of CNC machine and NC controller. A subscription to Fusion includes free access to a library of editable post-processors to create code to suit your needs.

If Easel suits your purposes, you will have CAD software, CAM software, simulator software, and control software all in one place – ideal for beginners or hobbyists who want a simple, stress-free CNC workflow. CNC programming is the process of converting a 3D model into machine-readable instructions in order to perform automated machining operations. Learn more about it here. Plus, learn how it’s used and all the important codes

cheap metal roofing sheets near me

Introduction to CNC: Understand the basics of CNC machining, its applications, and its significance in modern manufacturing. CNC Machine Components: Explore the key components of CNC machines and their functions, from the controller to the cutting tools. G-code and M-code: Grasp the essential programming languages used in CNC machining. CNC design software (CAD) lets you create 2D or 3D CAD designs; CAM software for creates toolpaths and exports g-codes that your CNC router can interpret; CNC controller software runs your machine to create perfect carvings and cuts One of the first things you’ll learn in the tutorial is how to run a CNC Machine like a Manual Machine. If you already know manual machining on a mill or lathe, you can be doing exactly the same kinds of things quickly on a CNC too. That’s one way to get productive a .CNC programming refers to the process of creating instructions or code that is used to control computer numerical control (CNC) machines. CNC machines are automated manufacturing tools that perform precise and complex operations on various materials, such .

CNC programming (Computer Numerical Control programming) is creating instructions for a CNC machine using software to control how it moves and interacts with the material workpiece. These machines include CNC milling machines, CNC lathes , and 3D printers. Understand the basics of CNC programming with our step-by-step guide. Gain a solid foundation in CNC programming principles and techniques. Learn how to analyze part diagrams and calculate tool paths. Discover the difference between manual and automatic CNC programming. Explore popular CNC programming software used by professionals. What is CNC Software? “CNC programming software (Computer Numerical Control Software) is software that allows mobile devices such as a computer to communicate with CNC machine tools like lathes, saws, plasma cutters, mills, etc.” Rather than having a human operator perform each task, CNC software essentially assists in the cutting and shaping.

Fusion is CAM software that can create high-quality CNC machining code for many types of CNC machine and NC controller. A subscription to Fusion includes free access to a library of editable post-processors to create code to suit your needs.

If Easel suits your purposes, you will have CAD software, CAM software, simulator software, and control software all in one place – ideal for beginners or hobbyists who want a simple, stress-free CNC workflow.

CNC programming is the process of converting a 3D model into machine-readable instructions in order to perform automated machining operations. Learn more about it here. Plus, learn how it’s used and all the important codes

Introduction to CNC: Understand the basics of CNC machining, its applications, and its significance in modern manufacturing. CNC Machine Components: Explore the key components of CNC machines and their functions, from the controller to the cutting tools. G-code and M-code: Grasp the essential programming languages used in CNC machining.

CNC design software (CAD) lets you create 2D or 3D CAD designs; CAM software for creates toolpaths and exports g-codes that your CNC router can interpret; CNC controller software runs your machine to create perfect carvings and cuts

er Metals, Inc., a wholly owned subsidiary of Otto Fuchs Metallwerke, is a premier supplier to the commercial and military aircraft-related industries. er forges high-performance aluminum and titanium structural components that support the leading members of the aerospace industry.

cnc machine program|different types of cnc programming