designing for sheet metal fabrication protolabs Get in-depth design advice to optimize your parts for sheet metal fabrication. Designing with fabrication requirements in mind can accelerate production time and reduce cost throughout the product lifecycle. Check out our wooden box with metal handles selection for the very best in unique or custom, handmade pieces from our boxes & bins shops.

0 · sheet metal prototyping near me

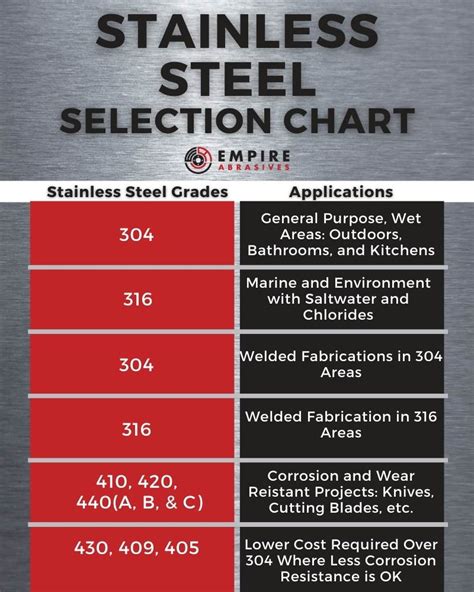

1 · sheet metal material selection chart

2 · sheet metal fab shop

3 · protolabs sheet metal thickness

4 · protolabs sheet metal design guide

5 · customized sheet metal fabricating price

6 · customized sheet metal fabricating factories

7 · customized sheet metal fabricating

$59.99

Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production .

Get in-depth design advice to optimize your parts for sheet metal fabrication. Designing with fabrication requirements in mind can accelerate production time and reduce cost throughout the product lifecycle.Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Tolerances vary on depending on part feature .Get in-depth design advice to optimize your parts for sheet metal fabrication. Designing with fabrication requirements in mind can accelerate production time and reduce cost throughout the product lifecycle.Deciding to use—or simply consider—sheet metal for an application is the first step in a process. The process begins, of course, with function, which in turn dictates design. Choosing a material and gauge are critical steps that involve balancing factors like strength, weight, and cost.

Need a crash course in sheet metal part design? This guide will help you improve manufacturability of your design by providing best practices for hems, countersink, holes, slots, bends, and more.

sheet metal prototyping near me

sheet metal material selection chart

LOCKHEED MARTIN turned to Protolabs for rapid sheet metal fabrication of solid aluminum parts to create a key piece of secondary infrastructure for a storage portion of the living quarters of NASA’s Gateway port.Designing sheet metal prototypes? Download our free sheet metal design guide to improve part manufacturability on features like hems, countersinks, holes and slots, bends, and more. Sheet metal prototypes and production parts from Protolabs. Get an instant quote.Our online sheet metal assembly service lets you create functional, end-use products delivered to you in days. With each project, you get design for manufacturability (DFM) feedback and expert-level support. You can choose from a broad range of finishing options to achieve your aesthetic requirements. Fabricated assemblies are frequently used for:Designing for sheet metal fabrication requires adherence to specific guidelines to ensure manufacturability and cost-effectiveness. This section outlines key design considerations and tips for working with Protolabs.

This white paper from Protolabs is an exploration of materials, manufacturing processes, design considerations and finishing options for sheet metal prototypes and low-volume production parts. Inside the white paper you will find: Why Sheet Metal? How is Sheet Metal Being Used? What Types of Sheet Metal are There?Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on two sheet metal fabrication processes: bending and laser cutting. How does sheet metal fabrication work?Our basic guidelines for sheet metal fabrication include important design considerations to help improve part manufacturability, enhance cosmetic appearance, and reduce overall production time. Tolerances vary on depending on part feature .

Get in-depth design advice to optimize your parts for sheet metal fabrication. Designing with fabrication requirements in mind can accelerate production time and reduce cost throughout the product lifecycle.Deciding to use—or simply consider—sheet metal for an application is the first step in a process. The process begins, of course, with function, which in turn dictates design. Choosing a material and gauge are critical steps that involve balancing factors like strength, weight, and cost.

sheet metal fab shop

Need a crash course in sheet metal part design? This guide will help you improve manufacturability of your design by providing best practices for hems, countersink, holes, slots, bends, and more.LOCKHEED MARTIN turned to Protolabs for rapid sheet metal fabrication of solid aluminum parts to create a key piece of secondary infrastructure for a storage portion of the living quarters of NASA’s Gateway port.

Designing sheet metal prototypes? Download our free sheet metal design guide to improve part manufacturability on features like hems, countersinks, holes and slots, bends, and more. Sheet metal prototypes and production parts from Protolabs. Get an instant quote.Our online sheet metal assembly service lets you create functional, end-use products delivered to you in days. With each project, you get design for manufacturability (DFM) feedback and expert-level support. You can choose from a broad range of finishing options to achieve your aesthetic requirements. Fabricated assemblies are frequently used for:Designing for sheet metal fabrication requires adherence to specific guidelines to ensure manufacturability and cost-effectiveness. This section outlines key design considerations and tips for working with Protolabs.This white paper from Protolabs is an exploration of materials, manufacturing processes, design considerations and finishing options for sheet metal prototypes and low-volume production parts. Inside the white paper you will find: Why Sheet Metal? How is Sheet Metal Being Used? What Types of Sheet Metal are There?

idaho sheet metal union

protolabs sheet metal thickness

$39.99

designing for sheet metal fabrication protolabs|protolabs sheet metal thickness