design electrical enclosures Key steps to consider for main electrical enclosure design: component selection; enclosure type and size; component layout; safety and regulations. Key code areas in NEC and NFPA 79: general operating . With Treo’s range of lunch box sets, you can keep rotis, chapatis, kulchas and other Indian breads separate from the curry. If you like carrying more than one curry, then you can choose lunch box sets that come with multiple containers.

0 · thermal insulation for electrical enclosures

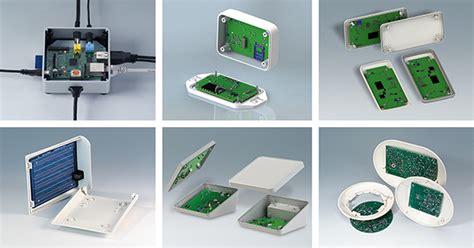

1 · pcb enclosure design guidelines

2 · inside of industrial electrical cabinet

3 · enclosure design of electronics equipment

4 · electronic enclosure design guidelines

5 · electrical enclosure types

6 · different types of wiring enclosures

7 · different types of electrical enclosures

Trellis Wall Brackets can be used to support wall-mounted trellises and to additionally stabilize free-standing trellises that are staked into the ground. Brackets hold trellises 3 inches from the wall with two stainless steel mounting screws.“The Speed Concept will accept both Dura Ace and Ultegra Di2. The battery is hidden in the seatpost with a special mount. And the junction box can be hidden inside the .

The environment in which the device needs to operate is an important consideration for the enclosure design. Apart from structural rigidity to withstand physical impacts and vibration, there are few other important considerations. Key steps to consider for main electrical enclosure design: component selection; enclosure type and size; component layout; safety and regulations. Key code areas in NEC and NFPA 79: general operating . As a first step in designing an enclosure, you need to choose the type of metal you will use and its thickness. Protocase stocks all of the metals generally used to make .nVent HOFFMAN is a leading designer and manufacturer of electrical enclosures to safeguard your people and equipment. Rely on us for smart, tailored solutions for your Energy, Industrial, .

electrical enclosure: 1) To protect electrical equipment inside the enclosure from the operating environment. 2) Protect users of the electrical equipment from electrical and/or mechanical .Chris Lloyd explains the basic decisions which need to be made when specifying an enclosure and how the right choice can reduce installation time and cost, and improve reliability. Whether you're an electrical installer, design engineer or an .

These six electrical panel enclosure design guidelines will ensure your precious equipment reaches the life expectancy you have in mind. A good design accounts for regulatory and application needs both physical and .

An enclosure has two basic tasks: housing and protecting sensitive electrical equipment from environmental contaminants and weather. Enclosures have volume and take up valuable space for.An electrical enclosure is a purpose-built cabinet designed to house electrical and electronic devices, providing the required protection to keep operators/personnel safe from electrical shock hazards and devices protected from hazardous environments as well as accidentalThe environment in which the device needs to operate is an important consideration for the enclosure design. Apart from structural rigidity to withstand physical impacts and vibration, there are few other important considerations. Electrical enclosure design involves several considerations to ensure that the final product can protect your electrical components. This article outlines them.

Key steps to consider for main electrical enclosure design: component selection; enclosure type and size; component layout; safety and regulations. Key code areas in NEC and NFPA 79: general operating conditions; protection from electric shock; protection of equipment; grounding; conductors and cables; wiring practices; marking and safety signs . As a first step in designing an enclosure, you need to choose the type of metal you will use and its thickness. Protocase stocks all of the metals generally used to make enclosures, including aluminum, stainless steel, carbon steel (cold-rolled steel or galvanneal) and copper.nVent HOFFMAN is a leading designer and manufacturer of electrical enclosures to safeguard your people and equipment. Rely on us for smart, tailored solutions for your Energy, Industrial, Commercial, Infrastructure and Communications applications.electrical enclosure: 1) To protect electrical equipment inside the enclosure from the operating environment. 2) Protect users of the electrical equipment from electrical and/or mechanical hazards of the equipment. 3) Potentially act as an interface between required human interaction with the electrical equipment. MODULARITY Modular design is .

Chris Lloyd explains the basic decisions which need to be made when specifying an enclosure and how the right choice can reduce installation time and cost, and improve reliability. Whether you're an electrical installer, design engineer or an OEM, the chances are that you deal with electrical enclosures on a day-to-day basis.

These six electrical panel enclosure design guidelines will ensure your precious equipment reaches the life expectancy you have in mind. A good design accounts for regulatory and application needs both physical and electrical: 1. Ratings & Standards. An enclosure has two basic tasks: housing and protecting sensitive electrical equipment from environmental contaminants and weather. Enclosures have volume and take up valuable space for.An electrical enclosure is a purpose-built cabinet designed to house electrical and electronic devices, providing the required protection to keep operators/personnel safe from electrical shock hazards and devices protected from hazardous environments as well as accidentalThe environment in which the device needs to operate is an important consideration for the enclosure design. Apart from structural rigidity to withstand physical impacts and vibration, there are few other important considerations.

Electrical enclosure design involves several considerations to ensure that the final product can protect your electrical components. This article outlines them. Key steps to consider for main electrical enclosure design: component selection; enclosure type and size; component layout; safety and regulations. Key code areas in NEC and NFPA 79: general operating conditions; protection from electric shock; protection of equipment; grounding; conductors and cables; wiring practices; marking and safety signs . As a first step in designing an enclosure, you need to choose the type of metal you will use and its thickness. Protocase stocks all of the metals generally used to make enclosures, including aluminum, stainless steel, carbon steel (cold-rolled steel or galvanneal) and copper.nVent HOFFMAN is a leading designer and manufacturer of electrical enclosures to safeguard your people and equipment. Rely on us for smart, tailored solutions for your Energy, Industrial, Commercial, Infrastructure and Communications applications.

electrical enclosure: 1) To protect electrical equipment inside the enclosure from the operating environment. 2) Protect users of the electrical equipment from electrical and/or mechanical hazards of the equipment. 3) Potentially act as an interface between required human interaction with the electrical equipment. MODULARITY Modular design is .Chris Lloyd explains the basic decisions which need to be made when specifying an enclosure and how the right choice can reduce installation time and cost, and improve reliability. Whether you're an electrical installer, design engineer or an OEM, the chances are that you deal with electrical enclosures on a day-to-day basis.

These six electrical panel enclosure design guidelines will ensure your precious equipment reaches the life expectancy you have in mind. A good design accounts for regulatory and application needs both physical and electrical: 1. Ratings & Standards.

sheet metal screw sizes

thermal insulation for electrical enclosures

pcb enclosure design guidelines

$0.73

design electrical enclosures|electronic enclosure design guidelines