cnc machine for ceramic Ceramic CNC (Computer Numerical Control) machining refers to a subtractive manufacturing process that utilizes computerized controls to operate and manipulate machine and cutting tools to shape stock ceramic material. Shop great deals on Stainless Steel Outdoor Kitchens. Get outdoors for some landscaping or spruce up your garden! Shop a huge online selection at eBay.com. Fast & Free shipping on many items!

0 · cnc tools for ceramics

1 · cnc machining process

2 · cnc machining methods

3 · cnc machining ceramics

4 · cnc machining ceramic parts

5 · cnc ceramic machine tolerance

6 · ceramic cnc machining process

7 · ceramic cnc machinery

Get the best deals on metal drawer cabinet when you shop the largest online selection at eBay.com. Free shipping on many items | Browse your favorite brands | affordable prices.

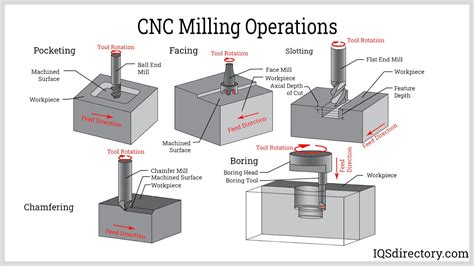

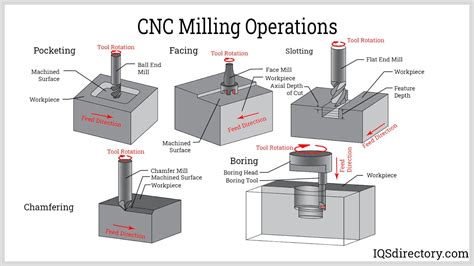

Ceramic CNC machining is a process where ceramic materials are sculpted into various forms using computer-guided tools. This process incorporates techniques like milling, drilling, grinding, and turning.

control box 110v 1000 watt electric element pot still

Ceramic CNC machining offers mechanical designers many benefits that traditional metals cannot match. From superior strength and durability to corrosion and wear resistance, ceramic components are ideally . Ceramic CNC machining works by utilizing computer numerical control (CNC) technology to shape and cut ceramic materials with precision. . Ceramic CNC (Computer Numerical Control) machining refers to a subtractive manufacturing process that utilizes computerized controls to operate and manipulate machine and cutting tools to shape stock ceramic material.

cnc tools for ceramics

In this comprehensive article, we delve into the world of ceramic CNC machining, exploring its principles, advantages, applications, design considerations, and the pivotal role it .In today’s precision-driven industries, Ceramic CNC machining is a leading solution. It leverages computerized technology to craft intricate, high-precision components, even from challenging ceramic materials used for CNC ceramic .

Ceramic CNC machining is a process where ceramic materials are sculpted into various forms using computer-guided tools. This process incorporates techniques like milling, drilling, grinding, and turning. CNC milling for ceramics is a process in which a computer-controlled machine uses a rotating cutting tool to remove material from a ceramic workpiece to create a desired shape or form. One of the key advantages of CNC milling for ceramics is the ability to produce complex shapes with high precision. Ceramic CNC machining offers mechanical designers many benefits that traditional metals cannot match. From superior strength and durability to corrosion and wear resistance, ceramic components are ideally suited for many industrial applications. Ceramic CNC machining works by utilizing computer numerical control (CNC) technology to shape and cut ceramic materials with precision. Ceramics, known for their hardness and brittleness, require specialized machining processes to achieve the desired results.

cnc machining process

cnc machining methods

Ceramic CNC (Computer Numerical Control) machining refers to a subtractive manufacturing process that utilizes computerized controls to operate and manipulate machine and cutting tools to shape stock ceramic material.

In this comprehensive article, we delve into the world of ceramic CNC machining, exploring its principles, advantages, applications, design considerations, and the pivotal role it plays in industries that demand high-performance ceramic parts.

In today’s precision-driven industries, Ceramic CNC machining is a leading solution. It leverages computerized technology to craft intricate, high-precision components, even from challenging ceramic materials used for CNC ceramic material work. Let’s see how people process it.

CNC machining is a common process that is done to manufacture components for various industries. It is compatible with almost all types of materials, including ceramics. If you want to learn about ceramic CNC machining, the guide below can offer you a lot of details. So let's read. What is Ceramic CNC Machining?Valley Design is a provider of high precision ceramic CNC machining services focusing on high quality, on demand 4 & 5 Axis CNC machining on all hard materials. Valley CNC machines ceramic materials such as Aluminum Nitride, 96% Alumina, 99.6% Alumina and Macor from our extensive inventory, or can modify customer supplied ceramic components.CNC machining is incredibly precise, perfect for making complex and detailed ceramic parts. It uses advanced machinery and software for excellent control over the cutting and shaping, resulting in high-quality, accurate components that meet strict standards.Ceramic CNC machining is a process where ceramic materials are sculpted into various forms using computer-guided tools. This process incorporates techniques like milling, drilling, grinding, and turning.

CNC milling for ceramics is a process in which a computer-controlled machine uses a rotating cutting tool to remove material from a ceramic workpiece to create a desired shape or form. One of the key advantages of CNC milling for ceramics is the ability to produce complex shapes with high precision. Ceramic CNC machining offers mechanical designers many benefits that traditional metals cannot match. From superior strength and durability to corrosion and wear resistance, ceramic components are ideally suited for many industrial applications.

Ceramic CNC machining works by utilizing computer numerical control (CNC) technology to shape and cut ceramic materials with precision. Ceramics, known for their hardness and brittleness, require specialized machining processes to achieve the desired results. Ceramic CNC (Computer Numerical Control) machining refers to a subtractive manufacturing process that utilizes computerized controls to operate and manipulate machine and cutting tools to shape stock ceramic material.

In this comprehensive article, we delve into the world of ceramic CNC machining, exploring its principles, advantages, applications, design considerations, and the pivotal role it plays in industries that demand high-performance ceramic parts.In today’s precision-driven industries, Ceramic CNC machining is a leading solution. It leverages computerized technology to craft intricate, high-precision components, even from challenging ceramic materials used for CNC ceramic material work. Let’s see how people process it. CNC machining is a common process that is done to manufacture components for various industries. It is compatible with almost all types of materials, including ceramics. If you want to learn about ceramic CNC machining, the guide below can offer you a lot of details. So let's read. What is Ceramic CNC Machining?

Valley Design is a provider of high precision ceramic CNC machining services focusing on high quality, on demand 4 & 5 Axis CNC machining on all hard materials. Valley CNC machines ceramic materials such as Aluminum Nitride, 96% Alumina, 99.6% Alumina and Macor from our extensive inventory, or can modify customer supplied ceramic components.

cnc machining ceramics

cnc machining ceramic parts

CNC milling machine is usually composed of shaft, worktable, spindle, frame, CNC controller, coolant, lubrication system, power tie rod, housing, axis, etc. How Does a CNC Milling Machine Work? Before running the CNC program, secure the workpiece to the worktable of the CNC milling machine, and mount the cutting tools on the spindle.

cnc machine for ceramic|cnc ceramic machine tolerance