metal fabrication safety topics What are some metal fabrication safety tips? Wear the proper protective gear. Make sure clothes are tight-fitting. Conduct regular equipment inspection. Keep work area organized. Implement safety rules. Train the workforce. In any .

Average Price: $5,960 - $12,740. Steel, aluminum, copper, and zinc are the four primary materials for metal siding. Whether corrugated, ribbed, bevel-style or vertical panels, metal continues to be highly versatile in its application for residential siding and wall cladding.

0 · sheet metal fabrication safety

1 · safety of metal fabrication

2 · metal fabrication safety standards

3 · metal fabrication safety requirements

4 · metal fabrication safety hazards

5 · metal fabrication safety clothing

6 · how dangerous is metal fabrication

7 · fabrication shop safety topics

The National Electrical Manufacturers Association (NEMA) assists in categorizing junction boxes by labeling them according to their usage type. Boxes for outside use are labeled as NEMA 3R .

Learn everything about Metal Fabrication Safety for your metal shop big or small. Let's discuss precautions, hazards and safety rules when working with metal.Any time injuries occur frequently and repetitively it’s worth a closer look. Following are the most common injures in mechanical industry fabrication shops, and safe work practices to help you . Tips to avoid cuts, burns, and eye injuries in welding and other metalworking environments. Jim Mosman lays out the best topics that a metal fabrication shop should address at its monthly safety meeting. Getty Images.This publication presents 52 safety talks that are specific to pipe fabrication shops. Topics covered include: general fabrication shop safety, personal protection, respiratory hazards, material handling, welding/cutting/brazing, fire .

This quick reference tool provides critical information on 61 safety and health topics that are specific to work performed by mechanical fabrication shop workers. The topics include .What are some metal fabrication safety tips? Wear the proper protective gear. Make sure clothes are tight-fitting. Conduct regular equipment inspection. Keep work area organized. Implement safety rules. Train the workforce. In any .

If your industrial ladder, platform, or skid isn’t constructed up to code, you could face steep OSHA fines or worse yet, a worker injury. But if you partner with an experienced, OSHA-savvy metal fabricator, they can apply your industry . Metal fabrication procedures involve several well-known safety risks and concerns but by understanding these key OSHA safety questions and managing the risks within your workplace will help prevent injuries and boost . Discover essential safety measures for your steel fabrication project. From training to equipment inspection, ensure worker safety and project success.

A safety-first operation will also make OSHA compliance front and center in their quality control program. 5: Implementing a Safety-Savvy Quality Control Program for OSHA-Compliant Fabrication. Experienced metal fabricators make safety . Working in metal fabrication can sometimes require employees to engage in high-risk activities in order to properly perform their duties, including weld and manufacture ferrous materials. If you manage or are responsible for .

What are some metal fabrication safety tips? Wear the proper protective gear; Make sure clothes are tight-fitting; Conduct regular equipment inspection; Keep work area organized; Implement safety rules; Train the workforce . In any .Metal Fabrication Shop Safety Program Manual. Need to add other topics to your safety manual? Topics such as: Safe Work Practices, Heat Stress, General Shop and Work Area, Ladder Safety, Confined Space and more, Only extra per chapter.3 Most Common Safety Concerns in Metal Fabrication. First, let’s cover the most common safety concerns within the metal fabrication industry, their costs, and an umbrella method of solutions. 1. Machine Guarding. According to OSHA reports, guarding and the proper usage of machinery cost the metal fabrication industry nearly million. Moving .

Metal fabricating. Here you'll find links to health and safety information and resources for work in metal fabricating. To reduce the potential for injury or disease, it's important to manage the risks and hazards in your workplace. See our resources to learn more about common risks and hazards in your industry, or follow the links to these related topics: Last year citations from the Occupational Safety and Health Administration (OSHA) cost metal fabricating businesses more than million. The actual cost of these violations is much higher, however, because it does not include other direct or indirect costs such as damaged facilities or equipment, medical costs, replacement personnel, and increased workers’ .Note: The directives in this list provide additional information that is not necessarily connected to a specific OSHA standard highlighted on this Safety and Health Topics page. National Emphasis Program - Primary Metal Industries. CPL 03-00-018, (October 20, 2014). Compliance Assistance for the Powered Industrial Truck Operator Training .

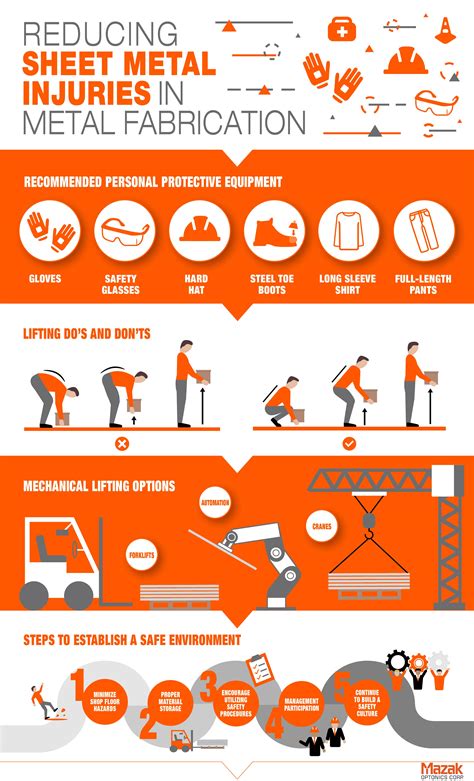

Metal Fabrication Safety. Maintain and wear personal protective equipment (PPE) such as safety shoes/boots, glasses, gloves, sleeves, and hearing protection; Be aware of the surroundings and accept responsibility for maintaining a safe environment; Understand accountability for their own safety and the safety of others in the shop12 Months of Safety Heat Stress and Related Illness All Safety Topics WorkSafeBC. By Type. Checklists Guidebooks Presentations Quick Reference Cards Safety Awareness Posters Safety Videos Templates Toolbox Talks 3rd Party Resources inars. . They are typically used during metal fabrication and construction-type of work. Toolbox Talk. Arc Flash.A place for anyone to discuss occupational safety-related topics, share news, and ask questions. . Sheet Metal Fabrication . I recently started learning and working as a sheet metal fabricator. The company I work for specializes in HVAC Ducts. The workshop is an old late 1800s warehouse-type design. Here is my main concern. There is dust .Ensure workplace safety in sheet metal fabrication. Learn about the critical safety requirements to protect workers and promote business success. . Provide comprehensive HSE guidelines and consultations to safety professionals and learn a lot of safety topics that will enhance your health and safety knowledge at the workplace including many .

Behind every successful metal fabrication is a safety-first workplace policy that includes welding safety best practices to protect employees on the shop floor. 1.888.421.9661 Find us on Twitter Find us on facebook Find us on Linkedin

Bonus: 7 Manufacturing Safety Tips. Here are some tips to help promote safety precautions within your manufacturing company: Promote frequent breaks – Breaks help workers who perform repetitive or awkward movements during their shift avoid musculoskeletal disorders. They can also prevent fatigue and combat heat stress in hot environments too.; Upgrade your . Discover essential safety measures for your steel fabrication project. From training to equipment inspection, ensure worker safety and project success. . workers in the construction and automotive manufacturing sectors .

Sheet Metal Fabrication (Topic 12 and 13) Topic: Prepared by: Ts Shikh Ismail Fairus B Shikh Zakaria Date: . List 5 safety measures while operating machines in metal fabrication lab. 2. List 3 main components of shearing machine or bending machine and briefly explain their functions. 3.CPWR leads national training programs focused on improving construction industry occupational safety and health and environmental remediation, reaching well over 50,000 workers per year. Learn More. . New topics are added on . Safety Tips When Fabricating Metal Components/ Instruments. The following steps can be employed when using metal fabrication tools: Proper Training: This is a very important step in any metal fabrication project.A detailed training session regarding the equipment, occupational hazards, and working conditions should be given to the personnel.

sheet metal fabrication safety

For people who work in the sheet metal industry, regardless of whether they’re performing standard or custom sheet metal fabrication, safety is paramount. Not only do experts work with a lot of machines, but they also handle sheets of metal and work in an environment that poses potential risks. The goal of top companies is to maintain safety .3444 Sheet Metal Work Establishments primarily engaged in manufacturing sheet metal work for buildings (not including fabrication work done by construction contractors at the place of construction), and manufacturing stovepipes, light tanks, and other products of sheet metal. . Occupational Safety and Health Administration 200 Constitution Ave NWStainless Steel Fabrication – Metal Cutting – Forming + Rolling – Welding – Finishing; Stainless Steel Machining – Milling – Turning/Lathe . Our team members are trained in vital safety topics on regular basis. Our safety team, comprised of ACE team members, rotates two times a year, giving every team member a chance to be further .

Safety Managers Play Key Role in Workplace Training. SafeStart notes managers play a key role in improving safety in metalworking facilities. “Metal fabrication and manufacturing is one of the toughest industries to develop elevated standards of safety because the work occurring on the floor is very high-risk,” writes SafeStart.

The metal fabrication process involves dealing with raw, rough and rugged metal components which are then cut, bent, welded and assembled to form desired metal structures. The main involvement of complex, engaging and intense steps like welding and cutting demands utmost safety precautions if the organization wants to keep their valuable .A Guide regarding individuals and managers functioning with Metal/Steel Fabrication. (1) - Critical ideas for the laborers in the steel fabrication area. Atlas Rigging & Transfer is associated with Hoisting, Rigging and Machine Moving Services since 30 years.8 WORKSAFE VICTORIA / A GUIDE TO SAFETY IN THE METAL FABRICATION INDUSTRY MANUAL HANDLING UNLOADING RAW MATERIALS When unloading raw materials, incidents have occurred where people use levers, such as metal bars to manually lever steel and other metal products off delivery vehicles. This practice is known as ‘barring off’. By using purpose . Sheet Metal Worker Safety. Sheet metal workers make, install, and maintain heating, ventilation and air duct systems (); metal building equipment (roofs, siding, gutters, downspouts, counters, and back splashes); signs, and vehicles. Factory and fabrication shop workers cut raw materials, then form and fasten them into end products for installation at .

Electrical Safety. Metal fabrication often involves working with electrical equipment. Always follow electrical safety procedures to avoid shock or electrocution. . Safety Topic: Sling Safety in .

local 512 sheet metal workers

lockable metal filing box

An electrical machine is link between an electrical system and a mechanical system. Conversion from mechanical to electrical: generator Conversion from electrical to mechanical: motor. Introduction.

metal fabrication safety topics|fabrication shop safety topics