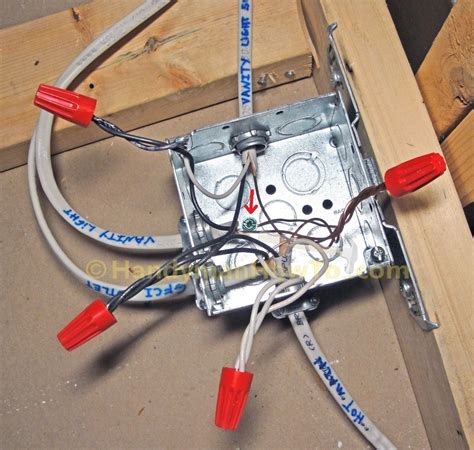

how to junction box awg 2 wire Nothing is more dangerous and aggravating than loose wires in a junction box. In this video you'll learn how to wire junction boxes correctly. You'll also see our favorite tools to. Metal fabrication software, also known as steel fabrication software, is software that enables manufacturers and metal fabricators to manage all processes related to metal fabrication.

0 · wire nuts in junction box

1 · junction box wiring diagram

2 · junction box wire size

3 · junction box wire replacement

4 · junction box wire connection

5 · junction box installation

6 · junction box #8 wiring

7 · how to wire junction box

Precision sheet metal fabrication is a manufacturing process that involves shaping raw metal sheets into finished products or components that will be assembled into a finished product. The metal sheet can be formed into a unique shape or “subtracted,” which means smaller shapes are cut from it.

I need to connect two 8/3 wires together in a junction box. What is the correct type of connector to do this? The two hardware stores I went to had nothing for 8 gauge wires.Disconnecting it from the AC unit or at the panel aren't very good options and . Nothing is more dangerous and aggravating than loose wires in a junction box. In this video you'll learn how to wire junction boxes correctly. You'll also see our favorite tools to. Disconnecting it from the AC unit or at the panel aren't very good options and would require digging into drywall or siding to free up the cable. My ideal method is to cut the cable, splice in an extra ~10 feet, and reroute it to .

A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one.

Installing an electrical junction box is a handy skill for any homeowner to know. Check out this video where we walk you through how to install an electrical junction box step by.

One essential component of DIY wiring is the junction box, a crucial element that ensures safe electrical connections. In this blog, we’ll guide you through the process of safely installing and using junction boxes, providing . If your house has visible wiring splices or if you need to add a new splice to extend a circuit, follow these simple steps to install a junction box.

Install the ground wire into a metal junction box. Connecting all the wires leaves you with one loose wire. This wire should be either green or copper-colored. Locate the ground screw inside the junction box, which must be . To splice cable that thick, you'll need to use butt connectors, which are barrels that are crimped on both ends of the conductor to couple the conductor ends together. A hydraulic . You can add up the conductor properties in either in² or circular mils to understand what Ideal is saying about the maximum capacity of their wire nuts. E.G., Ideal lists the max. for the blue 454 nut at 1 #6 and 2 #8's. A #6 .

It's power comes from the junction box 14/3 red wire. The wire to the outlet is just dangling the outside the wall (used to be behind the pantry cabinets) . on a limb assuming this multiwire was installed by an electrician . Look up "figure 8 coiling" before you install your wire - if you can't get enough people to have one standing by (each of) the middle box(es) while you pull it end-to end, pull from one box to the next and figure-8 coil the wire on the ground - then flip the coil over and pull the next segment (no tangles.) Just so the thread is useful to those who don't have access to the properties of electrical wire, here's how it goes: You can add up the conductor properties in either in² or circular mils to understand what Ideal is saying about . The junction box has the pigtail ground wire (bare copper) affixed to it. Additionally, there are also two bare copper wires. Follow the instructions that come with your junction box so that you connect the right wires together. You have to connect the 2 8-gauge wires which are white, to the blue wire connector inside the junction box.

The wire I'm using is 12 AWG stranded. The junction boxes are metal and sized at 4 x 2 1/8 deep. Additionally, the J boxes are just connection points. There are no outlets or switches in any of them. Wire is run to the junction via 1/2 EMT. 1/2 EMT allows for up to 9 conductors if 12 AWG. I have not exceeded that in any of runs. Questions: I'm .Otherwise you can only use it between junction boxes, which means 2 junction boxes. If you want to do it in one junction box, then buy 2 cords long enough to give you 8" slack inside the box, and splice there. . What Size Heat Shrink Tubing for Splicing Lamp Wire (SPT-2 .

The recommended size for a junction box for 6/3 wire is at least 4 11/16 inches by 2 1/8 inches. This size provides enough space for the wire and connectors, as well as room for future additions or changes. . The size of a conductor is expressed as AWG (American Wire Gauge); smaller numbers indicate larger wires. Common household wiring is .

What is the appropriate way to bond a metal junction box containing a receptacle wired with 6 AWG wire? It seems that most metal junction boxes have a 10-32 tapped hole to accept a ground screw but . Skip to main content. . Using some sort of ginormous wire nut to connect 2-6 and 1-12 AWG wires doesn't seem like the right move.

I have a 6" junction box with one 6 ga. wire for a 50 amp service. I'd like to "pigtail" this wire to two outlets.one for my welder and one for my plasma cutter. . The biggest wires i connected this week was only 10 x 450 awg ( double AL clamps) for a 400v, 3p, 440 A breaker. Might have a tiny idea about what i am talking about.Close and good info. Just the ground absolutely counts as a conductor in box fill. The 2020 nec code says up to 4 grounds counts as (1) of the largest size conductor.

custom sheet metal fabrication midvale

Let's run that through the voltage drop calc: 400'/480V/8A/5% => 14AWG @ 3.57% or 2.31% @ 12 AWG. That makes for rather cheap wire! Also, we only need 2 wires - the 480V run is isolated from both ends, . The junctions/splices of course need to be in a junction box, and junction boxes need to be accessible. Share. Improve this answer. FollowInstalling a Tyco Electronics no junction box splice connector.https://www.grainger.com/category/electrical/electrical-supplies/wire-connectors/non-metallic-.

That’s a good size, you don’t want any smaller, believe me...but I would suggest using a plastic nail on box. The metal one you showed me requires connectors and additional grounding. We offer the #1 Electrical Exam Prep ProgramFREE VERSION https://electricalcodecoach.com/free-exam-prep-programPRO VERSION https://www.electricalexamcoach.co. We offer the #1 Electrical Exam Prep ProgramFREE VERSION https://electricalcodecoach.com/free-exam-prep-programPRO VERSION https://www.electricalexamcoach.co. Wiring a electric range junction box #6 wire. Wiring a electric range junction box #6 wire.

The panel was replaced a couple years ago and the electrician at the time just put a few junction boxes around the panel to link the new breakers and modern wires to the existing paper wire runs. . The WT54 are rated for various sizes from 3 x 12 AWG on up to 2 x 6 AWG, so 1 x 6 AWG + 1 x 8 AWG will work great, and the 454 up to 1 x 6 AWG + 2 . Properly sized wire nuts will work fine. The typical ones most people use around the house won't handle larger than 10 AWG. Some examples of large-enough Ideal wire nuts are: 342 Gray, 454 Blue, B4 Blue, BT2 Red (just barely), WT54 Blue. An extra 10' and an extra 2 connections should not have any material effect on the circuit.There is a guideline based on the number of conductors and gauge. A normal single outlet box can only have two pieces of 12-2 in it where I live. The cubic inches is stamped on the box somewhere. PS- if you didn’t know this, you may be in over your head. And yes, that 12-2 is like a coat hanger and very hard to work with.

how to wire a junction box 10/3 wire consult with codes before doing electrical work

wire nuts in junction box

How do you splice large wires? One way to splice wires is by using a Polaris Connector. I will show you one in this video. In this video you'll learn how to wire junction boxes correctly. You'll also se. Nothing is more dangerous and aggravating than loose wires in a junction box. In this video you'll learn how to . Today I illustrate How to Connect 2 Receptacles from Single 14-3 Wire using Electrical Pigtails. I used the fluke no contact electrical voltage pen during my.

custom sheet metal fabrication sacramento ca

Joining #2 AWG copper to aluminum in a junction box . Going to a 100amp subpanel, outside in the conduit will be #2 copper (can't find #3) THHN so it's easier to pull and #2 SER aluminum inside so it can go in walls. . Use Noalox or eqivalent and abrade the aluminum with a wire brush or sandpaper to remove oxide. Best practice is to abrade it .

Answer = 6 × 3 in. = 18 in. [314.28(A)(2)] Sizing Tips for Pull Boxes and Junction Boxes. When sizing pull boxes and junction boxes, follow these suggestions: Step 1: Organize and always draw out the problem. Step 2: Calculate the horizontal distance(s): • Left to right straight calculation • Right to left straight calculation It has a #10 2 wire w/ground that runs through the attic and out an exterior wall in a junction box. I would like to use this circuit to power a garage with get this a "220 circuit". This would include installing a distribution panel in the garage.

How To Install An Electrical Junction Box. Types Of Electrical Wire Joints Engineering Discoveries. . Southwire Teck 6 3c 300 Type 90 Power Cable 1000 Vac 3 Awg Class B Stranded Copper Conductor Ft L. Southwire By The Foot 6 3 Stranded Romex Simpull Cu Nm B W G Wire 63950099.

custom sheet metal fabrication near me

custom precision sheet metal fabrication

custom sheet metal fabrication grande prairie

NC machines are cheaper than CNC machines, which require more maintenance. CNC machines have high accuracy and are flexible compared to NC controls; You require more time and expertise to execute a job when you use NC machines; CNC machines are fast and automated, needing less manual work.

how to junction box awg 2 wire|junction box wiring diagram