autodesk inventor to cnc machine In this class, we cover several ways to prepare and export data to CAM . The box, also known as a hot box or sweatbox, is a method of solitary confinement used in humid and arid regions as a method of punishment. Anyone placed in one would experience extreme heat, dehydration, heat exhaustion, or even death, depending on when and how long one was kept in the box. . See more

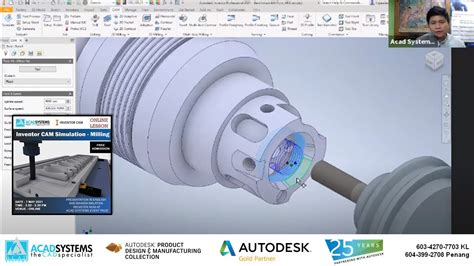

0 · inventor cam simulator

1 · inventor cam machining tutorial

2 · how to use inventor cam

3 · autocad inventor cam simulator

4 · autocad inventor cam model

5 · autocad inventor cam machining

What is BandLab Distribution? Before we begin, here’s a quick overview of BandLab Distribution. This feature is a brand-new offering that enables talented artists such as .

One of the NC machine shops we deal with uses Inventor which really works great for us. I send them the drawing along with the Inventor file. They are then able to import my IPT file directly into their CAM software.In Inventor, for a flat, extruded profile, use Save As and specify the matching file .Learn the key skills to set up a model in the CAM environment, assign toolpaths, and .We need to be able to produce DSTV format files so that we can easily .

In this class, we cover several ways to prepare and export data to CAM .

In Inventor, for a flat, extruded profile, use Save As and specify the matching file type your laser uses/reads/needs. If it's a sheet metal part, in the browser, activate the Flat .Learn the key skills to set up a model in the CAM environment, assign toolpaths, and generate the CNC code required by milling machines. We need to be able to produce DSTV format files so that we can easily produce parts on the CNC machines we have. Most of the time, these parts are 3D models that we . To do it manually you can create a new drawing on a sheet large enough, create a new sketch of your 4x8 on the drawing, then place your flat patterns on the sheet oriented in the sketch. You can do something similar in .

Yes, Autodesk Inventor can be used for CNC machines. Autodesk Inventor is a 3D computer-aided design (CAD) software that includes tools for designing and modeling parts and assemblies. It also has features for .Simulate created toolpaths in an Inventor CAM model. Generate the CNC code required to machine a model. This course focuses on instructing new users on how to use the Inventor . This Tutorial will show the viewier how to take a Assembly file made in AutoDesk Inventor and prepare it for Cutting operation for CNC Technology and machini.In this class, we cover several ways to prepare and export data to CAM software ready for CNC machining. After completing this class you will see that exporting manufacturing data from .

china underground electrical junction box

In this video tutorial we will show you how to use Autodesk Inventor to design two parts using a CAM program (CAMBAM) to apply machining operations to create the cutting profiles and drills to fabricate these two parts on the greenBull CNC . One of the NC machine shops we deal with uses Inventor which really works great for us. I send them the drawing along with the Inventor file. They are then able to import my IPT file directly into their CAM software. In Inventor, for a flat, extruded profile, use Save As and specify the matching file type your laser uses/reads/needs. If it's a sheet metal part, in the browser, activate the Flat Pattern node. Then, use Save As to the desired format.

Learn the key skills to set up a model in the CAM environment, assign toolpaths, and generate the CNC code required by milling machines. We need to be able to produce DSTV format files so that we can easily produce parts on the CNC machines we have. Most of the time, these parts are 3D models that we have created with Inventor. Sometimes, these parts are solid models that are given to us by our customers in the iges (or stp) format. To do it manually you can create a new drawing on a sheet large enough, create a new sketch of your 4x8 on the drawing, then place your flat patterns on the sheet oriented in the sketch. You can do something similar in a model and create your "material" and drop/constrain everything there.

Yes, Autodesk Inventor can be used for CNC machines. Autodesk Inventor is a 3D computer-aided design (CAD) software that includes tools for designing and modeling parts and assemblies. It also has features for generating tool paths and G-code for CNC machines.

Simulate created toolpaths in an Inventor CAM model. Generate the CNC code required to machine a model. This course focuses on instructing new users on how to use the Inventor CAM add-on to create milling toolpaths.This Tutorial will show the viewier how to take a Assembly file made in AutoDesk Inventor and prepare it for Cutting operation for CNC Technology and machini.In this class, we cover several ways to prepare and export data to CAM software ready for CNC machining. After completing this class you will see that exporting manufacturing data from Autodesk® Inventor® software is only part of the process.In this video tutorial we will show you how to use Autodesk Inventor to design two parts using a CAM program (CAMBAM) to apply machining operations to create the cutting profiles and drills to fabricate these two parts on the greenBull CNC machine.

One of the NC machine shops we deal with uses Inventor which really works great for us. I send them the drawing along with the Inventor file. They are then able to import my IPT file directly into their CAM software. In Inventor, for a flat, extruded profile, use Save As and specify the matching file type your laser uses/reads/needs. If it's a sheet metal part, in the browser, activate the Flat Pattern node. Then, use Save As to the desired format.Learn the key skills to set up a model in the CAM environment, assign toolpaths, and generate the CNC code required by milling machines.

inventor cam simulator

inventor cam machining tutorial

We need to be able to produce DSTV format files so that we can easily produce parts on the CNC machines we have. Most of the time, these parts are 3D models that we have created with Inventor. Sometimes, these parts are solid models that are given to us by our customers in the iges (or stp) format. To do it manually you can create a new drawing on a sheet large enough, create a new sketch of your 4x8 on the drawing, then place your flat patterns on the sheet oriented in the sketch. You can do something similar in a model and create your "material" and drop/constrain everything there. Yes, Autodesk Inventor can be used for CNC machines. Autodesk Inventor is a 3D computer-aided design (CAD) software that includes tools for designing and modeling parts and assemblies. It also has features for generating tool paths and G-code for CNC machines.

Simulate created toolpaths in an Inventor CAM model. Generate the CNC code required to machine a model. This course focuses on instructing new users on how to use the Inventor CAM add-on to create milling toolpaths.This Tutorial will show the viewier how to take a Assembly file made in AutoDesk Inventor and prepare it for Cutting operation for CNC Technology and machini.

In this class, we cover several ways to prepare and export data to CAM software ready for CNC machining. After completing this class you will see that exporting manufacturing data from Autodesk® Inventor® software is only part of the process.

chinese lunch boxes metal

1) All junction boxes will require a grounding screw "if" there are any splices in, or devices attached to that box. 2) Metal conduit (raceway) with the approved fittings can be considered grounded, thus eliminating the requirement for pulling a seperate circuit ground, but not eliminating the requirement of the grounding screw.

autodesk inventor to cnc machine|autocad inventor cam simulator