cnc aerospace parts This article explains what aerospace CNC machining is and the typical materials used in aerospace manufacturing. You’ll also learn about precision and tight tolerances in aerospace machining, multi-axis CNC . Best bet would be to hire another electrician, who will also say it is ok, then hire another electrician to check the last electrician and inspector. Or ask Reddit, which will also tell you that using an approved junction box is allowed.We either do that or pull them up or down and set boxes. Depends on the job. Sometimes they want the old panel gone.

0 · what is aerospace cnc machining

1 · cnc machining aerospace parts

2 · cnc airplane

3 · aircraft cnc machining

4 · aerospace manufacturing cnc machining

5 · aerospace connector manufacturing machine

6 · aerospace cnc machining services

7 · aerospace cnc machine shop

To square enclosures mounted on a wall or Unistrut frame, add shims as shown below. Shims should be made of a material such as stainless steel, aluminum, nylon, or plastic to reduce corrosion. An enclosure’s door sealing contact surface and the enclosure must be square in order to provide a reliable seal.

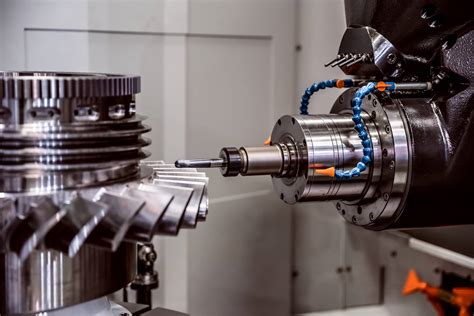

What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and . What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, . CNC machining, which involves the use of computer-controlled tools to manufacture parts with high accuracy, is a preferred method in the aerospace industry. For example, fuselage sections and aircraft landing gear . This article explains what aerospace CNC machining is and the typical materials used in aerospace manufacturing. You’ll also learn about precision and tight tolerances in aerospace machining, multi-axis CNC .

What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and spacecraft. What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry. CNC machining, which involves the use of computer-controlled tools to manufacture parts with high accuracy, is a preferred method in the aerospace industry. For example, fuselage sections and aircraft landing gear components require extremely tight tolerances and precision. This article explains what aerospace CNC machining is and the typical materials used in aerospace manufacturing. You’ll also learn about precision and tight tolerances in aerospace machining, multi-axis CNC machines for aerospace parts, and suitable finishing options. Let’s dive in!

By leveraging CNC machining technology, aerospace manufacturers can produce superior quality parts while minimizing waste and downtime. Precision and accuracy are paramount, as CNC machines deliver exceptional precision, ensuring that aerospace parts meet stringent industry standards .CNC Machining aerospace parts creates lightweight, durable materials and supports rapid prototyping, low-volume, and high-volume production, meeting strict safety standards while reducing lead times and minimizing human error.

what is aerospace cnc machining

Aerospace engineering plastics can be CNC-machined to create aircraft parts like cabin interiors, tray tables, wear pads, armrests, back-lit instrument panels, valve components, housings, tubing, and insulation. Explore how CNC machining produces precise, lightweight aerospace components, from complex parts to rapid prototyping, ensuring safety and innovation. Aerospace components are developed and designed using the best technology, ensuring they meet the highest standard.Whether you need hinges, bushings, manifolds, clamps or other custom manufactured parts, aerospace equipment and aircraft parts need the best components made with the highest quality metals in order to function properly. CNC machining is a good fit for manufacturing aerospace parts because the process is capable of achieving extremely tight tolerances for both plastic and metal parts. Here’s what you need to know about the key role CNC machining plays in aerospace manufacturing.

What Is CNC Machining for Aerospace? CNC machining for aerospace is a specialized manufacturing process that uses computer numerical control (CNC) machines to produce high-precision parts for aircraft and spacecraft. What is Aerospace CNC Machining? This CNC machining process involves creating CNC machining aerospace parts to assemble and maintain aircraft and space shuttles. Aerospace CNC machining companies use kits, components, and assemblies which are essential for crafts used in the aerospace industry.

CNC machining, which involves the use of computer-controlled tools to manufacture parts with high accuracy, is a preferred method in the aerospace industry. For example, fuselage sections and aircraft landing gear components require extremely tight tolerances and precision. This article explains what aerospace CNC machining is and the typical materials used in aerospace manufacturing. You’ll also learn about precision and tight tolerances in aerospace machining, multi-axis CNC machines for aerospace parts, and suitable finishing options. Let’s dive in! By leveraging CNC machining technology, aerospace manufacturers can produce superior quality parts while minimizing waste and downtime. Precision and accuracy are paramount, as CNC machines deliver exceptional precision, ensuring that aerospace parts meet stringent industry standards .

CNC Machining aerospace parts creates lightweight, durable materials and supports rapid prototyping, low-volume, and high-volume production, meeting strict safety standards while reducing lead times and minimizing human error. Aerospace engineering plastics can be CNC-machined to create aircraft parts like cabin interiors, tray tables, wear pads, armrests, back-lit instrument panels, valve components, housings, tubing, and insulation. Explore how CNC machining produces precise, lightweight aerospace components, from complex parts to rapid prototyping, ensuring safety and innovation. Aerospace components are developed and designed using the best technology, ensuring they meet the highest standard.

Whether you need hinges, bushings, manifolds, clamps or other custom manufactured parts, aerospace equipment and aircraft parts need the best components made with the highest quality metals in order to function properly.

cnc machining aerospace parts

cnc airplane

aircraft cnc machining

$408.45

cnc aerospace parts|cnc airplane