sheet metal fabrication pdf Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including .

What Does CNC Stand For? CNC stands for Computer Numerical Control. Essentially, it’s a technology that automates machine tools by using computers to control them. Instead of being manually operated by hand, CNC machines rely on a set of pre-programmed commands that tell the machine exactly what to do, making them highly efficient and precise .

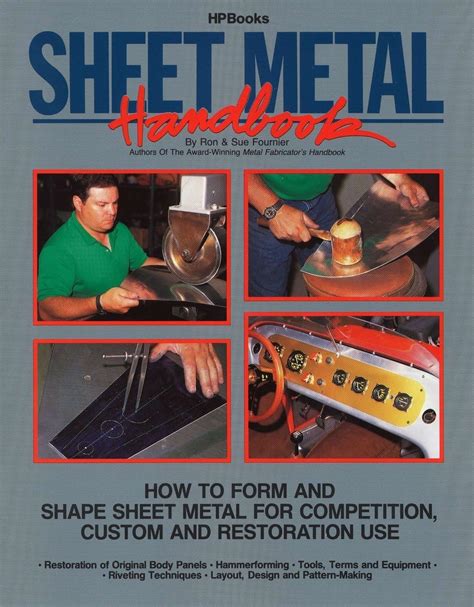

0 · sheet metal handbook free download

1 · sheet metal fabrication handbook pdf

2 · sheet metal die design pdf

3 · sheet metal design handbook pdf

4 · sheet metal design guideline pdf

5 · sheet metal design calculations pdf

6 · sheet metal calculations pdf

7 · sheet metal bending guide pdf

Some metal gussets are simple rectangles, used to fasten two boards that join at ends or meet at slight angles. This style is often used to splice two boards for parts of a truss or other roof element, like a ridge board, where a single board is too short.

Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental .The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material .

HANDBOOK OF STRUCTURAL STEELWORK. EUROCODE EDITION. First text page_Layout 1 04/10/2013 14:26 Page 1Understanding the costs of a sheet metal part will help you evaluate the choices each supplier is making to provide their price. First, let’s take a look at some of the key components of a sheet .Sheet metal fabrication involves punching, stamping, cutting, and bending metal sheets to form the desired shape. With technology, manufacturers use computer-aided 3D CAD programs to . Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including .

sheet metal handbook free download

Sheet metal fabrication is the process of forming parts from a metal sheet by punching, cutting, stamping, and/ or bending. 3D CAD files are converted into machine code, which controls a . Sheet Metal fabrication is the building of metal structures by cutting, bending, and assembling processes. It is a value added process that involves the construction of machines . sheet-metal-handbook Identifier-ark ark:/13960/t5bd3qk96 Ocr ABBYY FineReader 11.0 (Extended OCR) Page_number_confidence 80.95 Ppi 150 Scanner Internet Archive HTML5 Uploader 1.6.4 . PDF download. .

The document is a workshop report for a course on technology and handwork practice. It discusses sheet metalworking and provides details about the tools, processes, and activities involved. The objectives are to expose students to . Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including . First considerations -- Auto body metal -- The art of making sheet metal work with you -- Planning and implementing -- Major forming and fabricating processes -- Other processes and skills -- Finsihing processes and touches -- Filling with lead and plastic -- Tools and equipment -- The art of the English wheel -- Power-operated machines .Http://www.ETMmfg.com 56 UNDERSTANDING SHEET METAL COSTS Our Take on Profits The latest data published by Financial Research Associates for sheet metal fabricators with sales over million indicates that profits are very slim: Net sales Cost of sales Gross Profit Overhead Operating Profit Interest Depreciation Profit Before Tax ,000,000 .

This document provides fabrication procedures for structural steel work. It outlines requirements for materials, shop drawings, fabrication, safety, inspection, and painting. The fabrication process includes cutting, drilling, assembling, welding, repair, and quality control checks. Tolerances for welding and fabrication are specified in appendices. The goal is to fabricate structural steel .Report On Metal Fabrication - Free download as Word Doc (.doc / .docx), PDF File (.pdf), Text File (.txt) or read online for free. The document is a training report on metal fabrication submitted by Dhaval Manohar Jain to fulfill the requirements of a Bachelor of Technology degree. It provides an overview of various metal fabrication processes such as welding, drilling, grinding, and .Sheet metal fabrication involves punching, stamping, cutting, and bending metal sheets to form the desired shape. With technology, manufacturers use computer-aided 3D CAD programs to control the machines to cut and form the sheets into the final part with enhanced precision and accuracy. In high volume production and parts requiring low volume .

SHEET METAL FABRICATION 1. INTRODUCTION: Metal fabrication is the building of metal components and structures by cutting, bending, and assembling processes. A fab shop will bid on a job, usually based on the engineering drawings, to build the end product. Large fab shops will employ a multitude of value added processesGet an overview to sheet metal fabrication from the different types of sheet metal fabrication, to design best practices, materials, finishings and fastenings. 20% off your first order. Save up to ,000/€1,000. . Download PDF. Explore our knowledge base for more manufacturing and engineering resources Go to knowledge base. About; About us .

Sheet bending Sheet bending is defined as the straining of the metal around a straight axis. During bending operation, the metal on the inner side of the neutral plane is compressed, and the metal on the outer side of the neutral plane is stretched. Bending causes no change in the thickness of the sheet metal.

Chapter 6.Formulas for Sheet Metal Layout and Fabrication 6.1 6.1 Sheet Metal Flat-Pattern Development and Bending / 6.8 6.2 Sheet Metal Developments,Transitions,and Angled Corner Flange Notching / 6.14 6.3 Punching and Blanking Pressures and Loads / 6.32 6.4 Shear Strengths of Various Materials / 6.32 6.5 Tooling Requirements for Sheet Metal .Axis’ capability in precision sheet metal fabrication truly sets us apart from our competition. With the use of CNC equipment and highly skilled experienced craftsmen, Axis works with sheet metal in a number of ways that set us apart from the competition, and we’re proud to .Sheet Metal Duct Fabrication Standards (7.5 Hours) Trainee Instructor ISBN 978-0-13-609909-3 (Module ID 04204-08) Explains how to determine the requirements for a duct system, including operating pressures, metal gauges, connectors, reinforcements, tie rods, and seams.

7 Sheet and plate metalwork 277 7.1 Sheet and plate metalwork (introduction) 278 7.2 Roll-bending sheet metal and plate 296 7.3 Flow forming sheet metal 301 7.4 The principles of metal spinning 318 7.5 Swaging sheet metal 324 7.6 Basic fabrication procedures 330 Exercises 345 8 Structural steelwork and pipework 3471.1: Interpreting metal fab drawings 1.2: Blue Print Review 1.3: Joint types and Terminology 1.4: Basics of Welding Symbols 1.5: Supplementary Welding Symbols 1.6: Fillet Weld Symbols 1.7: Groove Welding Symbols 1.8: Plug Weld symbols 1.9: Spot, Seam, Stud Welding Symbols 1.10: Edge Weld Symbols 1.11: Process and Method 1.12: Pipe Symbols 1.13 .Estimating-Sheet-Metal-Fabrication-Costs-v3 19.pdf - Free download as PDF File (.pdf), Text File (.txt) or read online for free. This document discusses calculating material costs for sheet metal parts. It notes that simply multiplying the part .Sheet Metal Unfold Rule Equations. Register for more free training on this topic at KETIV Virtual Academy. Register Now. Free training, every week, from real experts. 9HUVLRQ 1R 3DJH RI .(7,9 $ &RQWHQWV

ºõ³ .The knowledge of Sheet Metal Fabrication is very useful in our day-today life and one needs to know at least the basics of the same. The content of this report includes an overview about the whole manufacturing fundamentals and the processes to be followed in this category in order to obtain the required final product. The report contains the . Sheet Metal fabrication is the building of metal structures by cutting, bending, and assembling processes. It is a value added process that involves the construction of machines and structures from various raw materials. This guide will help you to understand sheet metal product design tips and fabrication techniques. Metal. MetalworkingFabrication - Checklist - Free download as Excel Spreadsheet (.xls), PDF File (.pdf), Text File (.txt) or read online for free. The company has 10 years of experience manufacturing material handling structures and equipment. It has a 45,000 square foot facility with fabrication, welding, and machining capabilities. The company has 45 employees including 3 engineers and can .

FABRICATION REPORT - Free download as PDF File (.pdf), Text File (.txt) or read online for free. The document describes the fabrication process of a steel postbox. It includes objectives, safety measures, introduction to sheet metal fabrication techniques, work procedures, required apparatus, a discussion, and final product image. Key steps involve measuring, cutting, .Fabrication Inspection and Testing of Structural Metal Products 11-1-1 Topic No.: 675-000-000 Materials Manual Effective: August 19, 2004 Steel and Miscellaneous Metal Products CHAPTER 11.1 FABRICATION INSPECTION AND TESTING OF STRUCTURAL METAL PRODUCTS. 11.1.1 PURPOSE This procedure provides guidance for the development and implementation of

1.0 THEORY The term ‘sheet metal’ is used to mean metal having thickness in the range from 0.4mm to 6 mm. When the thickness is more than 6 mm, the metal is called a plate. Products made from sheet metal can be found almost anywhere. Metal tables, steel cabinets, car bodies, beverages cans and home appliances are some of the common examples. The .1.0 INTRODUCTION Sheet metal fabrication process In fabrication, sheet metal refers to thin, flat pieces of metal that are commonly used to create a wide variety of parts, structures, and products. The thickness of sheet metal typically ranges from 0.002 inches (0.05 mm) to several millimeters, though thicker materials are sometimes referred to as plate metal.

sheet metal fabrication handbook pdf

Metal fabrication : a practical guide by O'Con, Robert L. Publication date 2015 Topics Metal-work, Travail des métaux, metalworking, Metals Forming Publisher . Pdf_module_version 0.0.18 Ppi 360 Rcs_key 24143 Republisher_date 20220629024201 Republisher_operator [email protected] .

sheet metal die design pdf

sheet metal design handbook pdf

metal wolf chaos x box scans

Study with Quizlet and memorize flashcards containing terms like What does it mean if a metal is an alloy?, What are the general characteristics of all metals?, What is a ferrous metal versus a nonferrous metal, and what are examples of each? and more.

sheet metal fabrication pdf|sheet metal design guideline pdf