solidworks sheet metal cylinder Parts with cylindrical faces can be made of sheet metal if they meet the following criteria: Any adjacent planar and cylindrical faces must be tangent. At least one end face of any cylindrical . Wiremold (Legrand) Non-Metallic Cover Plate, OmniBox Series Floor Boxes, 1-Gang, Duplex Receptacle, (2) Flip Lids, Black. Mfr # 828PR-BLK. 88280270. Shop Now

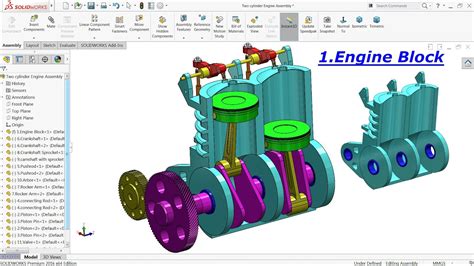

0 · solidworks training cylinder design

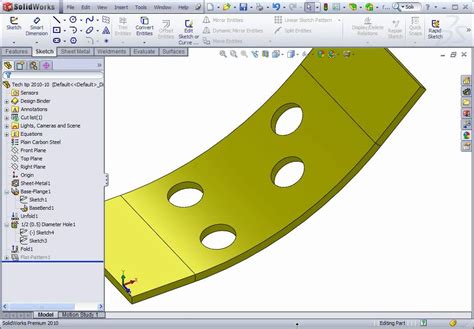

1 · solidworks sheet metal curved bend

2 · solidworks rolled sheet metal

3 · solidworks flatten cone

4 · solidworks conical sheet metal

5 · sheet metal cone in solidworks

6 · making a cone in solidworks

7 · flatten a cylinder in solidworks

A junction box provides a code-approved place to house wire connections, whether for outlets, switches, or splices. Here's how to install one.

Parts with cylindrical faces can be made of sheet metal if they meet the following criteria: Any adjacent planar and cylindrical faces must be tangent. At least one end face of any cylindrical . This video explores two methods for creating sheet metal cylinders. In this video, I'll show you how to use the Insert Bends command to tackle three common use cases for designing and flattening a rolled cylinder or cone. To .Parts with cylindrical faces can be made of sheet metal if they meet the following criteria: Any adjacent planar and cylindrical faces must be tangent. At least one end face of any cylindrical .

In this video you can see how to make a cylinder in SolidWorks, using Sheet Metal features. I hope you like this video.)) Please SUBSCRIBE on my channel for more videos and projects in.You can use the Rip tool to create rips in hollow or thin-walled cylindrical and conical bodies. By selecting an edge on a cylindrical or conical face, you can flatten the part as sheet metal. Slot .

yes! Create a circle profile with a very small gap, and then make a base tab, this will extrude to your selected length and material thickness. I have a Sheetmetal part, that I am designing, flat .

To create a sheet metal part with cylindrical faces: Sketch an open contour arc. The arc can also be tangent to a line. Single open contours can be used for extrudes, revolves, sections, paths, . In this video, I’ll show you how to use the Insert Bends command to tackle three common use cases for designing and flattening a rolled cylinder or cone in SOLIDWORKS Sheet Metal. This video tutorial show how to make a sheet metal cylinder in solidwrks. voice has been given so that everybody can understand very easily. it is a very use.The cylinder is now a sheet metal part. . sheet metal parts created with the Lofted Bends feature avoid this limitation and unfold appropriately. Parent topicSheet Metal Parts. Comparing Sheet Metal Design Methods. Bend Allowance and Bend Deduction Options. . Provide feedback on this topic. SOLIDWORKS welcomes your feedback concerning the .

Some people start with the sheet metal base flange option and use the centerpoint arc to a 359 deg segment to draw the cylinder and extrude it to whatever length. Then others will draw a complete circle and then break out a segment so its not connected and use the feature extrude, then later use INSERT BEND to make it into a sheet metal part.By using the Base Flange/Tab, create a circle with a small gap in it. That gap is for the cut on the sheet to make it possible to roll in a cylinder form. After that you just add your thickness and bend radius. If you can use your flatten view then you know the sheet has a correct bend in it. Checkout our free inar for SolidWorks BeginnersSheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .Hi! ( Noobie here) I would like to Basic Motion (Motion Study) a flat metal sheet to roll around a cylinder which is fixed on a stand (Eg. GIF attached). Can someone please guide me with a video tutorial or step by step procedure of how to achieve this effect. I'm using Solidworks 2015 (SP5) Thanks in Advance!

In this video, I'll show you how to use the Insert Bends command to tackle three common use cases for designing and flattening a rolled cylinder or cone. To .

Exercise 23 - Cylindrical Sheet Metal parts, Linear sketch patterns The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. . Bend sheet metal to wrap around and fit cylinder. BL By Brandon Lovatt 05/29/19. Hi all, I've been at this on and off for a while now and I can't come up with a solution. Any ideas how I can recreate this wing to wrap around the cylinder?Sheet Metal Part Won't Flatten I finally got my lofted bend to work between my two arc profiles, but now I cannot create a flat pattern from it. I'm not sure if it's the nature of the bends, or something else like a bend allowance that is making it so that the part won't flatten. This video tutorial show how to make a sheet metal cylinder in solidwrks. voice has been given so that everybody can understand very easily. it is a very use.

Parts with cylindrical faces can be made of sheet metal if they meet the following criteria: Any adjacent planar and cylindrical faces must be tangent. . The cylinder is now a sheet metal part. . Version: SOLIDWORKS 2022 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help.Sheet metal parts are generally used as enclosures for components or to provide support to other components. You can design a sheet metal part on its own without any references to the parts it will enclose, you can design the part in the context of an assembly that contains the enclosed components, or you can design the part within another part document in a multibody .Every year, SOLIDWORKS makes several enhancements to its software. In particular, they have made creating complex sheet metal parts even easier. Today we are going to look at creating a slot in a sheet metal cylinder. As you would expect, there are several ways to accomplish this in SOLIDWORKS. I will show you a couple [.] In this video, I'll show you how to use the Insert Bends command to design and flatten cone or rolled cylinder in SOLIDWORKS Sheet Metal. With over 35 years of experience, the TriMech Group offers a comprehensive range of design, engineering, staffing and manufacturing solutions backed by experience and expertise that is unrivalled in the industry.

The cylinder can not be 360°. It needs to have a break, ever so small. Make the partial cylinder, then use "Insert --> Sheet Metal --> Bends" to turn it into a sheet metal part. Select an edge to be the fixed portion. You can then use Fold and Unfold. Hi, This video demonstrates how to create an animation of sheet metal bends folding using SOLIDWORKS motion study and macros in a matter of few clicks: Animate folding of SOLIDWORKS Sheet Metal bends - YouTube Thanks, Artem Catalog. View .

Model is attached. Catalog. View in SOLIDWORKS User Forum View on Forum . Use your 3DEXPERIENCE ID to log in. Preview | SOLIDWORKS USER FORUM Sheet Metal Cylinder with Hem. PJ By Panfil Jim 08/13/20. Hey guys! Sheet metal question. I have a cylindrical body that I would like to put a hem along the top rounded edge. . Sheet Metal .

Parts with cylindrical faces can be made of sheet metal if they meet the following criteria: Any adjacent planar and cylindrical faces must be tangent. . The cylinder is now a sheet metal part. . EXPERIENCE SOLIDWORKS) 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help.

Parts with cylindrical faces can be made of sheet metal if they meet the following criteria: Any adjacent planar and cylindrical faces must be tangent. . The cylinder is now a sheet metal part. . Version: SOLIDWORKS 2024 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help.

The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. . Sheet Metal Cylinder with bent inward tabs. SG By Sam Groll 01/27/17. G'day Fellas, I am creating 2 halves of a cylinder and I want tabs on the top and bottom so I can mount them around my machine. I can make a base flange and then do an edge flange from that .The cylinder is now a sheet metal part. Only . then the model is not an exact cylinder and cannot be unfolded. However, sheet metal parts created with the Lofted Bends feature avoid this limitation and unfold appropriately. Parent topicSheet Metal Parts. . version SOLIDWORKS 2021 SP05 / ©2002-2024 .

By selecting an edge on a cylindrical or conical face, you can flatten the part as sheet metal. SOLIDWORKS supports straight cuts only, not slanted cuts. To create rips in cylindrical or conical models: . Version: SOLIDWORKS 2024 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help.

cnc glass polishing machine

When cuts are made into the flat pattern of a rolled sheet metal cylinder (or semi-cylinder), it is not always easy to extract model dimension data in a SOLIDWORKS drawing. Without proper design intent, detailing the flat pattern positions may not work. It might even require some significant user input for proper documentation.The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. I want to realize a sheet metal cylinder with dovetail joints in vertical (or a curve, etc.). I know realize only a sheet metal cylinder which combines a .how do I can draw and flatten cylinder in the sheet metal? Catalog. View in SOLIDWORKS User Forum View on Forum . Use your 3DEXPERIENCE ID to log in. Preview | SOLIDWORKS USER FORUM flatten cylinder - sheet metal. HN By Husein . ©2002-2024 Dassault Systemes SolidWorks Corporation .72K subscribers in the SolidWorks community. ALL posts related to SOLIDWORKS are welcome. Share what you know. . I’m trying to make a sheet metal cylinder with a lip in both sides, one inward, one outward. I’m putting relief cuts on the flat parts to not stretch and distort the metal. This is made using just features, and I want to .

solidworks training cylinder design

You can flatten all the bends of a sheet metal part at once. Creating a Sheet Metal Drawing. Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Completing the Sheet Metal Drawing. Next, add a view of the unfolded model.

solidworks sheet metal curved bend

EXTENDING POWER: The 2-gang outlet box allows you to add or extend power, .

solidworks sheet metal cylinder|making a cone in solidworks