solidworks sheet metal corners To create a closed corner, first add an edge flange to the base flange. Click Edge . Sigma's weatherproof two-gang boxes provide a junction for conduits and can house up to two wired devices such as a receptacle or switch. The rugged, die-cast construction prevents moisture penetration making the boxes suitable for wet, damp or dry locations.

0 · solidworks sheet metal welding

1 · solidworks sheet metal welded corner

2 · solidworks sheet metal relief cut

3 · solidworks sheet metal corner treatment

4 · solidworks sheet metal corner relief

5 · solidworks sheet metal closed corner

6 · solidworks sheet metal bend relief

7 · bending drawing sheet metal

IN BOX™ for new vinyl siding includes box with weatherproof-in-use cover, installed bug plugs, (1) standard duplex and (1) GFCI face plate, installation screws, and (1) NM cable connector. One-piece, recessed electrical box with weatherproof-in-use cover for stucco over masonry or wood construction. Also for cementitious/fiber rigid lap siding.

military surplus metal storage boxes

Create a sheet metal part that includes the area you want to close off. For example, you can use the closed corner feature to close off the open space between the adjacent, angled edge .To create a corner-trim: Create a sheet metal part. Click Corner-Trim (Sheet .

To create a closed corner, first add an edge flange to the base flange. Click Edge .To create a corner-trim: Create a sheet metal part. Click Corner-Trim (Sheet .You can add a corner relief to a single sheet metal body. Use the Corner Relief .To create a corner-trim: Create a sheet metal part. Click Corner-Trim (Sheet Metal toolbar) or click Insert > Sheet Metal > Corner Trim. In the Corner-Trim PropertyManager, set the following .

milton steel lunch box snapdeal

To create a closed corner, first add an edge flange to the base flange. Click Edge Flange (Sheet Metal tab). Select the edge as shown. In the PropertyManager: Under Angle, set Flange Angle . In this video, I am going to explain about Closed Corners, Welded Corners, Break/Trim Corners in SolidWorks Sheet Metal.-----. Solidworks Sheet Metal Corner Treatment For Beginners to understand how to user corner option in Solidworks sheet metal and how to use Solidworks sheet metal corner treatment.To create a corner-trim: Create a sheet metal part. Click Corner-Trim (Sheet Metal toolbar) or click Insert > Sheet Metal > Corner Trim. In the Corner-Trim PropertyManager, set the following .

In this video and blog, we will dig into one of the most powerful tools in SOLIDWORKS Sheet Metal that allows you to close corners.You can add a corner relief to a single sheet metal body. Use the Corner Relief PropertyManager to apply corner treatments to a folded sheet metal body that persist in the flattened state. .

Use the Corner Relief PropertyManager to apply corner treatments to a folded sheet metal body that persist in the flattened state. See how and when specifically to design bend reliefs and corner reliefs in sheet metal parts to open up geometry options & tighter tolerancesClick Closed Corner (Sheet Metal tab). Select the face of the base flange as shown for Faces to Extend. Select Butt for Corner type. Click . Parent topic . EXPERIENCE SOLIDWORKS) 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help.Now add a closed corner to one side of the base flange. A closed corner extends a flange so that the gap between two flanges is narrowed. To create a closed corner, first add an edge flange to the base flange. Click Edge Flange (Sheet Metal tab). Select the edge as shown.

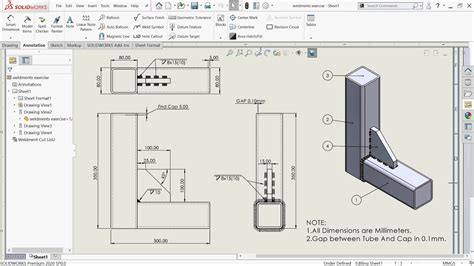

Now create a drawing of the sheet metal part. Start with an isometric view of the folded model, and then add a view of the unfolded model. Click Options (Standard toolbar).; On the System Options tab, click Drawings > Display Style.; Under Tangent edges, select Visible, and click OK.; Click Make Drawing from Part/Assembly (Standard toolbar) or File > Make Drawing from Part, .Sheet-Metal contains the definition of the sheet metal part. This feature stores the default bend parameter information (such as thickness, bend radius, bend allowance, auto relief ratio, and fixed entity) for the entire part. Flatten-Bends represents the flattened part. This feature contains information related to the conversion of sharp and .

Turns out the Sheet Metal environment has dedicated tools that can achieve the same result with one feature – the Close Corners command. While this team would have benefited from attending Surface Modeling for other use cases, the course they needed the most of the SOLIDWORKS Sheet Metal training.

Search 'Adding Weld Beads to Sheet Metal Corners' in the SOLIDWORKS Knowledge Base. Provide feedback on this topic. SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic directly to our documentation team.The Welded Corner PropertyManager allows you to add a weld bead to the corners of a folded sheet metal part, including miter flanges, edge flanges, and closed corners. . Version: SOLIDWORKS 2020 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help.Search 'Adding Weld Beads to Sheet Metal Corners' in the SOLIDWORKS Knowledge Base. Provide feedback on this topic. SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic directly to our documentation team.Click Closed Corner (Sheet Metal tab). Select the face of the base flange as shown for Faces to Extend. Select Butt for Corner type. Click . Parent topic . SOLIDWORKS) 2024 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > .

Use the Corner Relief PropertyManager to apply corner treatments to a folded sheet metal body that persist in the flattened state. To open the Corner Relief PropertyManager: . EXPERIENCE SOLIDWORKS) 2025 SP0 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help. The first is in the initial Sheet-Metal feature that is created when your part is made using the sheet metal tools (or converted to sheet metal). From here you can select to have relief added automatically on bends that require it. . The last method for creating relief in SolidWorks applies to corner relief. We discussed previously that .You can add a corner relief to a single sheet metal body. Click Corner Relief (Sheet Metal toolbar) or Insert > Sheet Metal > Corner Relief.; In the Corner Relief PropertyManager, under Corner Type, select a two or three bend corner.; Under Scope, select the sheet metal body to which to apply the corner relief.; Under Corners , click Collect all corners to list all corners in the sheet .

Solidworks Sheet Metal Corner Treatment For Beginners to understand how to user corner option in Solidworks sheet metal and how to use Solidworks sheet metal.Use the Corner Relief PropertyManager to apply corner treatments to a folded sheet metal body that persist in the flattened state. To open the Corner Relief PropertyManager: . Version: SOLIDWORKS 2021 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help.

You can add flanges to your sheet metal part with corners that are automatically mitered. First you add a notch to limit the propagation of the miter flange. Then you add and dimension the sketch for the miter flange. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form .Sheet Metal Welded Corners. To add weld beads to a sheet metal corner: Click Welded Corner (Sheet Metal toolbar) or Insert, Sheet Metal, Welded Corner. Select one of the corner faces. . SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and .Use the Corner Relief PropertyManager to apply corner treatments to a folded sheet metal body that persist in the flattened state. To open the Corner Relief PropertyManager: . Version: SOLIDWORKS 2024 SP05 To disable help from within SOLIDWORKS and use local help instead, click Help > Use SOLIDWORKS Help.

The closed corner feature adds material between sheet metal features, and includes the following capabilities: Close multiple corners simultaneously by selecting the faces for all of the corners that you want to close. Close non-perpendicular corners. Apply a closed corner to flanges with bends other than 90°. Adjust the Gap distance. The .Posted by u/Funkit - 9 votes and 2 comments

solidworks sheet metal welding

Searching YouTube for "solidworks sheet metal corners" or a specific feature name will get you a bunch of results. Reply reply Top 2% Rank by size . More posts you may like r/learnprogramming. r/learnprogramming. A subreddit for all questions related to programming in any language. .When you flatten a sheet metal part by unsuppressing the Flat-Pattern feature, corner treatments are automatically applied to create a clean, flattened sheet metal part. The corner treatments are applied so the flat pattern is correct for manufacturing. . Search 'Using Corner Treatments' in the SOLIDWORKS Knowledge Base. Provide feedback on .Search 'Adding Weld Beads to Sheet Metal Corners' in the SOLIDWORKS Knowledge Base. Provide feedback on this topic. SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic directly to our documentation team.

Search 'Adding Weld Beads to Sheet Metal Corners' in the SOLIDWORKS Knowledge Base. Provide feedback on this topic. SOLIDWORKS welcomes your feedback concerning the presentation, accuracy, and thoroughness of the documentation. Use the form below to send your comments and suggestions about this topic directly to our documentation team. So why does Sheet metal Welded corner only work in certain circumstances? I have a part that I want the corners closed within .0625", corner to corner with an open bend region, to give the welder a closer butt joint to weld (it has to be like this so the drawing \ flat pattern is correct).The Sheet Metal weld corner doesn't work when the flange is not colinear to .

Hey, I'm working on a sheet metal part, and I'm having trouble getting a closed corner. I hope this makes sense; I have a corner with three bends, which means the flat pattern leaves it open. Attached is a photo of a manufactured bend that is closed. .Create a sheet metal part that includes the area you want to close off. For example, you can use the Closed Corner feature to close off the open space between the adjacent, angled edge flanges. Click Closed Corner (Sheet Metal toolbar) or Insert, Sheet Metal, Closed Corner. Select one or more planar faces for Faces to Extend .

The home for the SOLIDWORKS Forum. REAL People, REAL Experiences, REAL Knowledge. . a small gap between the mitred corners of the top angled flange. Is there a method of creating a similar corner in an assembly of sheet metal components. I have attempted to assemble two folded sheet metal sections overlapping at the corner and then "cut .

solidworks sheet metal welded corner

solidworks sheet metal relief cut

Safeguard outdoor electric wires and cable terminals from dust and low-pressure water jets with an IP55 junction box. IP55 junction boxes are ideal for low-level weather damage protection. Find waterproof socket covers to keep electricals safe from dust and water jets.

solidworks sheet metal corners|solidworks sheet metal corner treatment