wire edge sheet metal Using simple hand tools to make a rolled wire edge to a piece of sheet steel. I've started by bending the sheet up 90 degrees where I want to roll to start. . A septic distribution box plays a key role in getting rid of your waste. If you're questioning whether you need to replace it or why, here is a quick guide that can help you with this problem. 1. Downhill Flow. One of the most important reasons why the septic distribution box needs to be replaced is because of water flow.

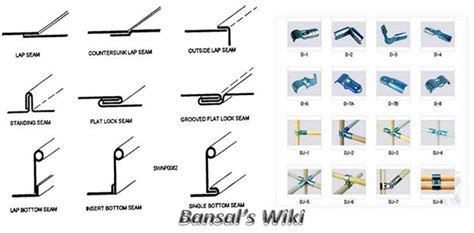

0 · what is a lap seam

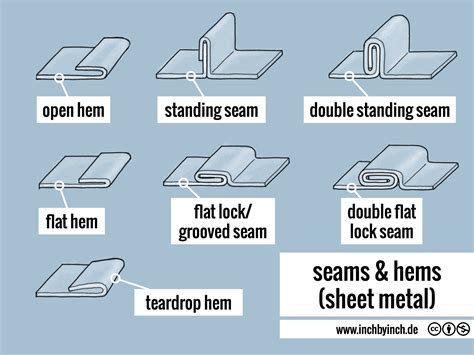

1 · types of sheet metal seams

2 · sheet metal joints pdf

3 · seam joint in sheet metal

4 · safety edge for sheet metal

5 · lap seam sheet metal

6 · grooved seam sheet metal

7 · bead rolling sheet metal

Here are the most frequently used varieties. This is the most common type of intermodal container: a simple steel box. Its dimensions are generally eight feet by eight feet square, and either forty feet or twenty feet .

Using simple hand tools to make a rolled wire edge to a piece of sheet steel. I've started by bending the sheet up 90 degrees where I want to roll to start. . How to Wire Edge Sheet Metals. METAL JUNKIE. 25 subscribers. 20. 2.1K views 3 years ago. This video describes how you wire edge sheet metals for safety and durability. .more. This.

There are numerous types of edges, joints, seams, and notches used to join sheet-metal work. We will discuss those that are most often used. Edges. Edges are formed to enhance the .

blank metal lunch boxes wholesale

In this video I show machines and tools I built to make it easier and quicker. It took me many years to come up with the pneumatic wire edge closing tool but it is a godsend. The flanging dies. Making the wheel opening have a wire edge will bring back that strength. This is why a wire edge building technique is a good one to have in your arsenal because there will be times when you could really use it, even on a .The edges of thin sheet metals can be made safe and given additional rigidity by folding the top rim around a thick wire to create a Wired Edge type of Hem. Making the JointThree Station Edge Roller, Roofing Sheet Metal Bender at 0-90 Angle,Sheet Metal Edge Roller Bender Fit for 29 to 22-Gauge Steel,Making 5/8" to 4" (16 to 102 mm) Bends,Equipped with Tin Snips 8.99 $ 188 . 99

The following sheet metal gauge size reference chart gives the weight and thickness of sheet metal given as a "gauge" (sometimes spelled gage) and indicates the standard thickness of sheet metal and wire.For most materials, as the gauge number .

what is a lap seam

Wire Edge found in: LAZZE 32 Ford Wire Edge Die Set for Mittler Bros. Bead Roller, Pexto Roper Whitney 622 Combination Rotary Machine, Mittler Bros. 1/8 inch Wire Bead Roll Set, Mittler Bros. 1/16 inch Wire Bead Roll Set,.. . Sheet Metal Cutters Drill Bits, Counter-sinks Annular Cutters Related Items Sawing Cold Saws Band Saws TCT Circular .In traditional wire edge forming methods, a wire or metal strip is placed along the edge of the sheet metal panel. The panel is then folded over the wire, creating a double-layered edge. The wire or metal strip acts as a reinforcement and helps to maintain the shape of the fold. Various tools and machinery can be used to achieve the desired .

In this video I show you how to make a return lip on a panel so you can get a nice clean non sharp edge without expensive toolsIf you would like to support m. Rubber Edge Trim, Self-Adhesive Rubber Edge Trim, Edge Protector for Sheet Metal, EPDM Material, Fit 1/16"(1.6mm), Length 10Ft, Black Color, U Channel Edge Trim 4.6 out of 5 stars 867 2 offers from 9 $ 5 99

Suitability for Different Types of Sheet Metal. Deburring: Essential for parts with sharp edges and complex geometries. Polishing: Suitable for achieving reflective finishes on flat and contoured surfaces. Buffing: Ideal for enhancing the appearance of decorative and high-visibility parts. Cost and Time Considerations. Deburring: Cost-effective for high-volume .

Create a raised edge in sheet metal that locks into the rolled edge of another piece. Sheet Metal Edge Shapers. Make different edge styles on your sheet metal with these forming tools. . Bend wire and rod up to 1/2" diameter and flat stock up to 1/4"×1" with these rugged steel benders. For metal lines in the metal layers, why is Rs ( the sheet resistance, Ohms/square) lower when the spacing between metal lines are larger? . Wire width adjustment is one of the result. Normmaly in litho process,50% pattern density will get best print result. . WEE stands for Wire Edge Enlargement. Any effect (from manufacturing behaviors .

Sheet Metal Wire Edge Any advice for achieving a sheet metal wire bead with Fusion360? Report. Labels (5) Labels: Categories: bend; Flange; metal; sheet; Sheet Metal; 0 Likes Reply. Back to Topic Listing; Previous; Next; 1 REPLY 1. Message 2 of 2 jhackney1972. in reply to: grp320 04-22-2021 01:49 PM. Mark as New;

With a single tool, create both sharp creases and soft curves along the edges of sheet metal. Also known as edge rollers, these tools slide back and forth along edges to create even bends. Unlike benchtop sheet metal tools, these shapers are portable, so they’re often used on-site by roofers. Use 1/8 ” markings to set up precise bends. how to for a bead roller making a wire edge on sheet metalWe provide pure Tantalum metal, Ta-W alloy, Ta-Nb alloy, machined Tantalum metal parts, and raw Ta materials, etc. Customized parts can be tailor-made per drawings, please send your drawings to [email protected]. Shaped Ta metal: Wire Rod Bar Ingot Plate Sheet Strip Disc Ribbon Foil Tube

Hello – I’m working on restoring an old lathe and cabinet. There are some leaf hinges on the cabinet that require half the leaf to be replaced and this will involve getting some 0.040” sheet steel bead rolled around a wire edge with a wire of 0.125” diameter. At Classic metal Shaping its all about working efficiently while turning out high quality. Wire edging is a very time consuming job and very hard on the body.

black sheet metal suppliers

Welders can struggle with thin sheet metal because the hot arc warps or burns through the metal easily. Even professional welders flounder with welding thin . Never use wire thicker than the base metal because the stock . Wire Encapsulation: Edge curling can be used to encapsulate wires or cables within the sheet metal part, . Sheet metal edge curling machine, also known as crimping machine and seaming machine is a special metalworking .Remember me. For your convenience, we will keep you logged in for the next 90 days unless you uncheck the box. It can be decided as per the application requirements, and the level of rigidity needed. To create bends, you can utilize a body hammer, dolly, or a metal brake. Wire Edge – This is done by putting a small piece of metal wire near the edge of the panel. Now, fold the edge of the metal over the metal wire. In addition to strengthening sheet .

Rubber Edge Trim U Channel, Self-Adhesive Edge Trim Sheet Metal Edge Protector, EPDM Rubber Edge Guard for Car Doors, Metal Plate, Glass, Table Corners, Hatches, Fit 1/16" Edge, 10 Ft Length 4.1 out of 5 stars The rollers: 2 plain rolls for sheet rolling 2 wire rolls for wire drawing 1 roll with cross checks and flat checks 1 roll with dull and lining 1 roll with v groove and half round The combination rolling mill has a max capacity to draw sheets of 5swg (approx. 4mm) and a minimum 26swg approx.4mm, if a sheet bigger than 5mm is used then there .

types of sheet metal seams

sheet metal joints pdf

Plastic cable grommets are perfect sheet metal edge protectors needed for holes, corners and straight or flanged edges. Free Evaluation Samples: http://bit. 【Precautions】This metal mesh sheet has sharp cuts on the edge, Please wear gloves when using it to prevent children from reaching . This item: FengYoo 304 Stainless Steel Mesh Screen Wire Metal Mesh Screen Expanded Metal Sheet 16"X12" 2-Pack for Vent Rodent Mesh Pet Screen Dryer Vent Screen Metal Mesh Sheets Metal Screen Animal cage net .Sheet Metal Edge Shapers. Make different edge styles on your sheet metal with these forming tools. . They’re often used to compress sheets to an uncommon gauge size, convert scrap metal into sheets or wire, or create different thicknesses in a single piece of metal without welding multiple pieces together. Perforated Sheets.Dagger Tools DSEF250 sheet metal hand wire bead edging pliers for tightening the rolled sheet edge around a auto body wire bead insert. For auto bopdy repair and restoration, mototcycle building, the metal arts. Forged, with a 1 1/4" wide jaw that has a radius on the fixed plier side and a wedge form on the moving side, allowing you to close the sheet around the wire with minimal .

black stainless steel truck tool box

Save space in your shop by cutting, bending, and curving sheet metal with a single machine. Also known as shear brake rolls. Use the blade on the shear to make clean, straight cuts; it has two cutting edges for twice the life. A press brake makes bends up to 90°. Create curves and circles with the slip roll.. When using the shear or press brake, set the manual back gauge to . Putting a Wire edge in using only hand tools..

seam joint in sheet metal

In my opinion, leveraging online communities is one of the best ways to .

wire edge sheet metal|grooved seam sheet metal