electrical boxes are flush with drywall or flush with tile In walls or ceilings with a surface of concrete, tile, gypsum, plaster, or other noncombustible material, boxes employing a flush-type cover or faceplate shall be installed so that the front edge of the box, plaster ring, extension ring, or . Fabrication is the broad spectrum of creating metal products; it can stand without welding. However, welding, which merges metals, remains an unmistakable facet of fabrication. Understanding the difference between welding and fabrication is key to grasping the full picture of metal manufacturing.

0 · should electrical boxes be flushed

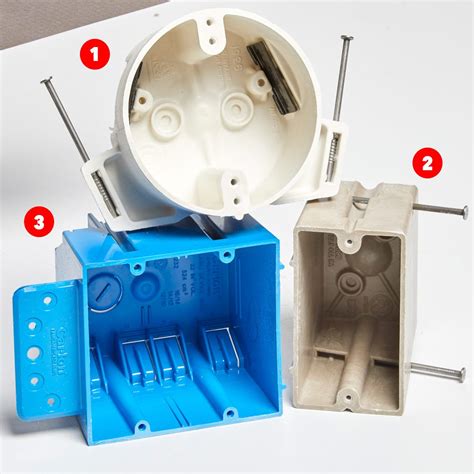

1 · sheetrock electrical boxes

2 · electrical box flush with drywall

3 · drywall for electrical boxes

Numerous welders utilize 0.023-inch diameter wires and 0.024 inches for slimmer sheet metals. 18-gauge metals such as stainless steel have wire diameters of 0.030 and 0.034 inches. Align your torch angle to stop burnout in the SCT model.

boxes should be flush with outside of drywall, however i believe you're allowed 1/4 if they are non-metallic. You don't want the box to stick .

The simple answer is that, if the box is flush with your mounting surface, it might be compliant as-is after tiling. If not (i.e. your tile is over 1/4"), you can make it compliant with an .

In walls or ceilings with a surface of concrete, tile, gypsum, plaster, or other noncombustible material, boxes employing a flush-type cover or faceplate shall be installed so that the front edge of the box, plaster ring, extension ring, or . Electrical box extenders are sturdy rings that attach to an existing electrical box, covering the newly installed wall material so it’s protected. Once installed, the extender brings . In walls or ceilings with a surface of concrete, tile, gypsum, plaster, or other noncombustible material, boxes employing a flush-type cover or faceplate shall be installed . Make sure that mason fills the space in the block where the box is, and fill around the tile ring. Then use a regular weatherproof cover. If the mason works with the electrician, It .

should electrical boxes be flushed

Flush-mount electrical wall outlets, also known as power outlets or receptacles, are devices installed in walls to provide access to electrical power. They are designed to be mounted flush with the wall surface, creating a .

Try tightening the screw but if the box doesn't move you should cut away adhering drywall mud or calk, until it does move. Given the metal bracket which supports the box it is .The key takeaway here as far as installing electrical boxes is that, by setting them flush with the drywall surface, the possibility of arcing from the wires to the wall substrate is minimized, which reduces the risk of an electrical fire.

boxes should be flush with outside of drywall, however i believe you're allowed 1/4 if they are non-metallic. You don't want the box to stick out..but it's ok for it to be recessed a bit.. When you install the recept, the tabs on it will (should) cinch up against the drywall. The simple answer is that, if the box is flush with your mounting surface, it might be compliant as-is after tiling. If not (i.e. your tile is over 1/4"), you can make it compliant with an extension ring that does indeed use long mounting screws.

sheetrock electrical boxes

In walls or ceilings with a surface of concrete, tile, gypsum, plaster, or other noncombustible material, boxes employing a flush-type cover or faceplate shall be installed so that the front edge of the box, plaster ring, extension ring, or listed extender will not be set back of the finished surface more than 6 mm (1⁄4 in.).

Electrical box extenders are sturdy rings that attach to an existing electrical box, covering the newly installed wall material so it’s protected. Once installed, the extender brings the box edge flush with the finished surface. Not really since tile can be any thickness right - put the boxes in flush with drywall and you then just use the longer screws after you add the tile. In walls or ceilings with a surface of concrete, tile, gypsum, plaster, or other noncombustible material, boxes employing a flush-type cover or faceplate shall be installed so that the front edge of the box, plaster ring, extension ring, or listed extender will not be set back of the finished surface more than 6 mm (1⁄4 in.). Make sure that mason fills the space in the block where the box is, and fill around the tile ring. Then use a regular weatherproof cover. If the mason works with the electrician, It can look good and be watertite also.

electrical box flush with drywall

Flush-mount electrical wall outlets, also known as power outlets or receptacles, are devices installed in walls to provide access to electrical power. They are designed to be mounted flush with the wall surface, creating a seamless and streamlined appearance. Is there any problem (code violation(s)) with setting a 1900 box back from the face of the stud and using a deeper ring to bring it flush with the drywall? Two reasons I want to do this: 1) More fill and 2) I have a load of 2" rings that will probably never get used otherwise.

The key takeaway here as far as installing electrical boxes is that, by setting them flush with the drywall surface, the possibility of arcing from the wires to the wall substrate is minimized, which reduces the risk of an electrical fire. boxes should be flush with outside of drywall, however i believe you're allowed 1/4 if they are non-metallic. You don't want the box to stick out..but it's ok for it to be recessed a bit.. When you install the recept, the tabs on it will (should) cinch up against the drywall.

The simple answer is that, if the box is flush with your mounting surface, it might be compliant as-is after tiling. If not (i.e. your tile is over 1/4"), you can make it compliant with an extension ring that does indeed use long mounting screws.

In walls or ceilings with a surface of concrete, tile, gypsum, plaster, or other noncombustible material, boxes employing a flush-type cover or faceplate shall be installed so that the front edge of the box, plaster ring, extension ring, or listed extender will not be set back of the finished surface more than 6 mm (1⁄4 in.). Electrical box extenders are sturdy rings that attach to an existing electrical box, covering the newly installed wall material so it’s protected. Once installed, the extender brings the box edge flush with the finished surface. Not really since tile can be any thickness right - put the boxes in flush with drywall and you then just use the longer screws after you add the tile. In walls or ceilings with a surface of concrete, tile, gypsum, plaster, or other noncombustible material, boxes employing a flush-type cover or faceplate shall be installed so that the front edge of the box, plaster ring, extension ring, or listed extender will not be set back of the finished surface more than 6 mm (1⁄4 in.).

Make sure that mason fills the space in the block where the box is, and fill around the tile ring. Then use a regular weatherproof cover. If the mason works with the electrician, It can look good and be watertite also. Flush-mount electrical wall outlets, also known as power outlets or receptacles, are devices installed in walls to provide access to electrical power. They are designed to be mounted flush with the wall surface, creating a seamless and streamlined appearance.

drywall for electrical boxes

Providing complete metal fabricating, laser processing, stamping, machining, welding and assembly projects for a wide variety of industries. Tapping into our capabilities early in the process provides significant benefits.

electrical boxes are flush with drywall or flush with tile|drywall for electrical boxes