sheet metal fabrication wiki Metalworking is the process of shaping and reshaping metals in order to create useful objects, parts, assemblies, and large scale structures. As a term, it . American Metals Supply, Inc. is a Wholesale Metals Distributor specializing in aluminum products. Main products include Aluminum Extrusions, Bars, Coil, Sheet and Plate, for a variety of applications including Industrial, Structural and Architectural products.

0 · various sheet metal processes

1 · types of sheet metal process

2 · types of sheet metal fabrication

3 · sheet metal manufacturing process types

4 · sheet metal manufacturing guide

5 · how to fabricate sheet metal

6 · how is sheet metal manufactured

7 · basics of sheet metal fabrication

Todos los productos se fabrican con la última tecnología CNC .

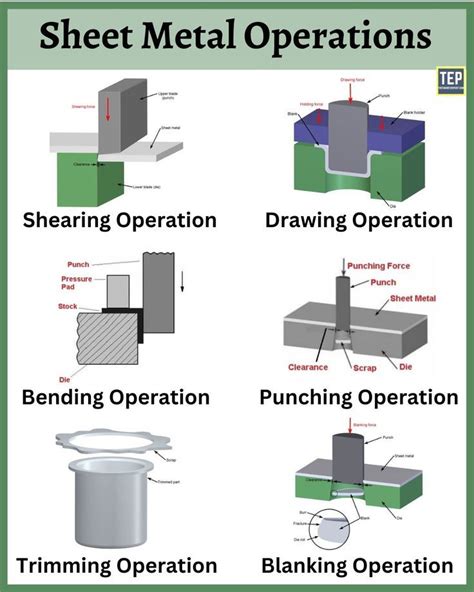

• Cutting is done by sawing, shearing, or chiselling (all with manual and powered variants); torching with handheld torches (such as oxy-fuel torches or plasma torches); and via numerical control (CNC) cutters (using a laser, mill bits, torch, or water jet). • Bending is done by hammering (manual or powered) or via press brakes, tube benders and similar tools. Modern metal fabricators use press brakes to coin or air-bend metal sheet into form. CNC-controlled backgauges use hard stops to p.

Metalworking is the process of shaping and reshaping metals in order to create useful objects, parts, assemblies, and large scale structures. As a term, it . Sheet metal fabrication is an essential process for many industries, enabling the creation of complex and precise metal components. Understanding the various fabrication techniques is crucial for effective decision-making, cost .Sheet metal fabrication is not only a pivotal technology that sheet metal technicians need to grasp, but also an important process of sheet metal product forming. Sheet metal fabrication includes traditional cutting, punching, .Sheet metal fabrication is a process of working with metal, used in various industries, ranging from construction and automotive to warehouse and electronics. It involves transforming flat sheets of metal into functional .

The manufacturing & design guide. Learn how to effectively design sheet metal parts. This guide starts with the basics and moves toward design best practices and advice on material selection, finishings and fastenings, with a focus on .Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal. [1] Commonly used equipment include box and pan brakes , brake .

various sheet metal processes

Versatility. Sheet metal fabrication machines can shape metal into intricate and complex geometries, allowing for the creation of sophisticated and innovative products. They .There are many sheet metal materials suitable for stamping fabrication. Sheet metal materials widely used in the electronic and electrical industry include: 1. Ordinary cold rolled sheet SPCC SPCC refers to the continuous rolling of steel . Complex Sheet Metal Fabrication know-how materials:1, good shape of the sheet metal materials more in line with the requirements of complex Sheet Metal Fabrication and manufacturing, to have a permanent effect under the external deformation of the ability to be destroyed.For cold parts, there should be good cold plastic, such as auto parts .

1. Sheet Metal Fabrication, processing a large number of tolerances, so the difficulty of processing, is greater or smaller? For this problem, the Sheet Metal Fabrication plant in Wuxi high running answer is the processing of the higher the level of tolerance level, so the processing is less difficult because the level of the digital, the average size of the allowable .AmHawk has the sheet metal fabrication equipment and machines necessary to produce everything from simple cutouts, to high tolerance complex bend and multiple piece products. We have more than 35 different pieces of equipment designed to cut, shear, burn, punch, bend, drill, form, grind, and weld. Most importantly, we have craftsmen with the .Sheet metal fabrication is a key technology that technicians need to master, and. In the metal fabrication industry, we often hear the words automotive sheet metal fabrication and precision sheet metal fabrication. Are the two the same? Then the editor tells you that there is a difference between the two. Different!Microscopic close-up of mild steel sheet metal. Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel.. Sheet metal is available in flat pieces or coiled strips.

Online sheet metal fabrication service. Get custom parts delivered in just a few days—upload STEP or DXF files for instant pricing! . Available on sheet metal and plastic. Hole Operations. Hardware, Tapping, Countersinking. Dimple Forming +1-2 days. Finishing Options. Anodizing, Plating, Powder Coating, Tumbling.

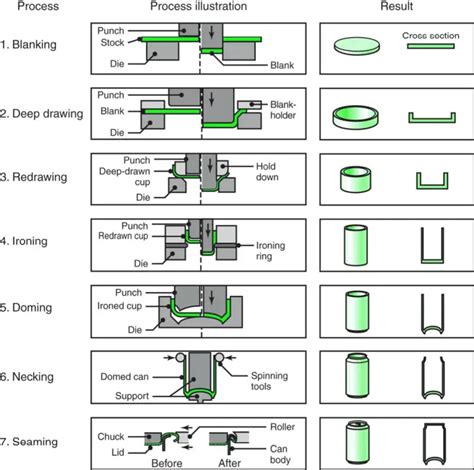

A fireman turning a bar of metal on a lathe on the USS Harry S. Truman (CVN 75) in 2004. Metalworking is the process of shaping and reshaping metals in order to create useful objects, parts, assemblies, and large scale structures. As a term, it covers a wide and diverse range of processes, skills, and tools for producing objects on every scale: from huge ships, buildings, .Bending A chimney starter, a sample product of bending. Bending is a manufacturing process that produces a V-shape, U-shape, or channel shape along a straight axis in ductile materials, most commonly sheet metal. [1] Commonly used equipment include box and pan brakes, brake presses, and other specialized machine presses.Typical products that are made like this are .Rolling schematic view Rolling visualization. In metalworking, rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough.Rolling is classified according to the temperature of the metal rolled.Animation of a power press with a fixed barrier guard. Stamping (also known as pressing) is the process of placing flat sheet metal in either blank or coil form into a stamping press where a tool and die surface forms the metal into a net shape. Stamping includes a variety of sheet-metal forming manufacturing processes, such as punching using a machine press or stamping .

The Fabrication Station (or "Fabristation") is an interactive computer terminal and attached pneumatic tubing in the far corner of the garage backrooms. It allows The Driver to purchase item blueprints and car and garage upgrades in exchange for Anchor Energy and some incidental raw materials. Purchased blueprints and upgrades are deposited immediately next to the terminal .What Is Sheet Metal Fabrication. Sheet metal fabrication is not only a pivotal technology that sheet metal technicians need to grasp, but also an important process of sheet metal product forming. Sheet metal fabrication includes traditional cutting, punching, bending, welding and other methods to form different shapes.

Sheet metal is available in flat pieces or coiled strips. The coils are formed by running a continuous sheet of metal through a roll slitter. In most of the world, sheet metal thickness is consistently specified in millimeters. In the U.S., the thickness of sheet metal is commonly specified by a traditional, non-linear measure known as its gauge.Sheet Metal Fabrication. Sheet metal fabrication involves the cutting, bending and welding of sheet metal to build various machines and structures. One of the core competence of our parent company, HCS Engineering continues to carry that .Facility Our 8000-square-foot, Toronto-based facility is a hub for a diverse range of sheet metal fabrication services, including those for elevators, escalators, interior design, commercial areas, and film and movie sets, showcasing our .The Sheet Metal Door is the most common door found on bases due to its resistances to melee weapons and fire but relatively cheap cost to craft. Regardless, it is still relatively weak to explosives compared to its expensive .

Sheet metal fabrication’s vast construction applications are due to the durability, strength, high weather resistance, manufacturability, versatility, aesthetic qualities, and other beneficial properties of various sheet metals, including steel, aluminium, and copper. One of countless examples of sheet metal fabrication in the construction .

In a box-and-pan brake (also known as a finger brake [1]), the clamping bar includes several removable blocks, which may be removed and rearranged to permit bending of restricted areas of a piece of sheet metal or of already partially formed pieces.. After bending, the box or pan form is then completed by screw, solder, weld, rivet, or other metal fixing process.Automated Sheet Metal Fabrication and Robotics Are The Future; Should Your Sheet Metal Manufacturing Partner Be Tech-Savvy? 5 Hints You Are Working With The Right Plastic Injection Molding Manufacturer; Injection Molding Tooling Tips- The Key To Success; Plastic Injection Molding Design Tips

Semiconductor device fabrication, the process used to create semiconductor devices and integrated circuits in everyday electronic devices; Art fabrication, production of large or technically difficult artworks; Metal fabrication, the building of metal structures by cutting, bending, and assembling; Prefabrication, assembling components of a structure and transporting them to .Resistor based on the sheet resistance of carbon film. Sheet resistance is the resistance of a square piece of a thin material with contacts made to two opposite sides of the square. [1] It is usually a measurement of electrical resistance of thin films that are uniform in thickness. It is commonly used to characterize materials made by semiconductor doping, metal deposition, .

Material Selection: The choice of the sheet metal material depends on various factors, such as the specific requirements of the building, the local climate, and the budget. Common materials used for gutter fabrication include steel, aluminum, copper, and zinc. Design and Planning: A well-thought-out design and planning phase are crucial for ensuring that the gutters are tailored to .

Many industries require sheet metal fabrication in Sydney. Sheet metal fabrication is used for industries such as automotive, aerospace, construction, manufacturing, civil works, heavy engineering, energy and mining and more because it is a versatile and cost-effective way to create custom metal parts and structures with high precision and .

Most of the aluminum sheet metal parts are made of 6061、6063 , 1100-H44, 3003-H12 aluminum sheets and pipe fittings.Because of its light weight, high strength and rigidity, the shape can be arbitrarily complex, the material consumption is low, and machining is no longer required.The surface is smooth and clean, so it is widely used in daily life and industrial production, such as . It is crucial to understand the various sheet metal fabrication techniques available to fully comprehend the process of forming multiple components utilizing sheet metal. The processing procedures for sheet metal make the transformation of two-dimensional metal sheets into three-dimensional, functional pieces. The following list contains the .

types of sheet metal process

Tiled, framed, suspended or draped, GKD metal fabrics conform to regular and irregular ceiling surfaces. Beyond the material’s striking aesthetic, metal fabric ceilings effectively hide wiring, plumbing, ductwork, mechanicals and support structures yet they are fire-proof and allow for the free flow of air and sprinkler system water.

sheet metal fabrication wiki|sheet metal manufacturing guide