how far back does electrical box go into wall Most residential is 1/2- or 3/8-inch thick, so keep a handful of drywall strips of this thickness on hand to facilitate electrical box installation. If you are using a different wall . CNC Replacement Parts provides direct replacement parts for Spindle Drive Belts, Encoder Belts, Encoder Pulleys, Switches, and more. 100% Free Shipping in USA! Call us today!

0 · old electrical box installation

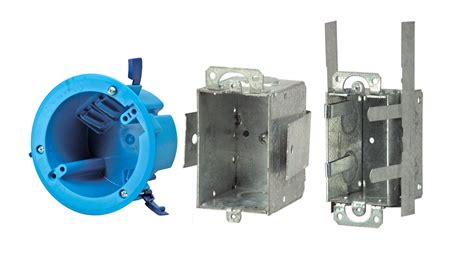

1 · installing electrical box in finished wall

2 · how to install electrical boxes

3 · extending electrical box

4 · electrical boxes for walls

5 · electrical box installation distance

6 · depth of electrical boxes

7 · depth of electrical box installation

Explore our range of high-quality CNC custom bicycle parts at Huayi International Industry Group Limited. Perfect for customizing your ride. Shop now!

old electrical box installation

how is a steel electrical enclosure made

Do electrical boxes have to be flush to the finished surface? Can they recess any depth into the wall by as much as 1/8" or 1/4"? How to Install an Electrical Box in a Finished Wall. Follow these expert tips to install an electrical box into drywall or plaster without the need for wall studs or joists. Total Time: 30 minutes. Skill Level: Kid-friendly. Wiring installation is easier before the walls and ceilings get covered with drywall or plaster. Installing electrical boxes the depth of drywall while studs and joists are . Most residential is 1/2- or 3/8-inch thick, so keep a handful of drywall strips of this thickness on hand to facilitate electrical box installation. If you are using a different wall .

The key takeaway here as far as installing electrical boxes is that, by setting them flush with the drywall surface, the possibility of arcing from the wires to the wall substrate is minimized, which reduces the risk of an electrical fire.

No gap is allowed between the front of a panel box and the wall surface that the dead front of a recessed panel will sit against in a regular wood stud (combustible) wall structure, but a 1/4” gap is acceptable in a . Make sure the box you choose has enough space to accommodate all the wires and connections without overcrowding. Allied Moulded Products offers a wide variety of electrical boxes to suit a variety of needs, . On concrete or block walls, surface-mount boxes and conduit are the way to go. These boxes can be plastic or metal. Because they’re exposed, they need to be mounted perfectly plumb and level. They also require conduit . If the box is set back into the wall, snap off the ears at the score marks and put them on the screws. Use one, two or more as necessary to get the device tight to the box and .

Use the bubble level and place the electrical box firmly on the wall. Then use the pencil to trace the outline of the box. . they cling to the front of the drywall. Essentially, the remodel box has support at the front and back of .

Do they make old work boxes with flappers that go back further so they can get behind a thick wall? Sometimes you have to put a receptacle in a cabinet with a 3/4" back panel on top of a 1" wall (plaster and wood lath) and .Go to electrical r/electrical. r/electrical . But where the holes are located in the box you may technically need an arc shield due to how far back it may end up . If I tighten the side screws the box will just get pulled into the wall. The box has .It can be seen that the box is mounted with 1 screw and 1 nail, driven into a block of wood that extends from the wall stud. Since the box is only mounted on one side, it bends on the said side when pulled, especially when pulled from the GFCI outlet (the right side of the last photo below, opposite of the screw+nail).

installing electrical box in finished wall

In this video I am showing you how to fix a box that is too far back in the wall. Per code you cannot install a device in the box if tis more than 1/4 inch r. 314.20 In Wall or Ceiling. (2008 NEC) In walls or ceilings with a sur-face of concrete, tile, gypsum, plaster, or other noncombustible material, boxes employing a flush-type cover or faceplate shall be installed so that the front edge of the box, plaster ring, extension ring, or listed extender will not be set back of the The holes for the boxes are slightly set away from the wall so that the conduit does not mount flush against the wall. I have found various types of single screw and double screw support clips that are intended for holding the conduit flush to the wall, but that would require an offset fitting at each box. When UL approves the box, they also approve the labeling on the box, and the instruction sheet intended to go with the box. Of course, big-box stores buy by the carton, sell them loose in bins, and don't give you the instruction sheet. But it should be on the Internet.

They are designed to be recessed 1/8". Take a plastic box. Slide it against a 2x4 until it hits the stud stops. Measure the distance the box protrudes past the face of the 2x4. That distance is 3/8". (You can do this at Home Depot if you don't stock these items.)

When drilling into the wall, how do I make sure I can avoid drilling into the wires behind the wall? . fasteners. Use a screw that will not penetrate into the wall more than two inches (1.5" of wood plus 1/2" drywall). As far as between the studs, drill as small hole only the depth of the drywall, then use a piece of wire or tip of a .If the box is not required to hold the weight of a light fixture it need only be securely fastened. For example, you can get a 3-gang "old work" box designed to be attached only to the drywall.Which one you pick can have more to do with what cable is coming into the box: NM vs metal jacketed.

2 or 4 screws for attaching the outlet plug(s) to the electrical box. (You may need ones that are longer than the current ones. Measure before buying.) Electrical Box Extender, Shimming Plate, or Outlet Spacers; Electrical/Voltage Tester; Go to the electrical box and turn off the power to the outlet box you are working on. Slip it into the hole and line it up with the top on the hole. Screw it to the wall from the outside. Cover the screw heads with drywall patching compound or even white toothpaste will work. Unscrew the mounting screws on the box making sure the ears are down. Insert the box into the wall and tighten the box mounting screws. My wife bought a wall switch/outlet plate, and I immediately realized that normal plates are convex, a bit of gap for the screws holding the outlets to the electrical box. I am thinking I can leave the screws off, and instead bend back the metal tabs at the top and bottom of the switches, burying them in plaster.tive. The second option is far more common. If there is access above the light (in an attic or kneewall space), you can remove the wire from the existing fixture box and install it in a junction box. You can then splice on a new piece of wire (make sure it is the same wire gauge) and run the new piece from the junction box back to the fixture .

Installations within or behind a surface of concrete, tile, gypsum, plaster, or other noncombustible material, including boxes employing a flush-type cover or faceplate, shall be made so that the front edge of the box, plaster ring, extension ring, or listed extender will not be set back of the finished surface more than 6 mm (¼ in.). Is there a better way to do this? There are certainly different ways to do this. A typical UK ceiling-rose for a pendant lamp. Wires are secured by screw terminals in brass blocks which are built into the plastic-bodied ceiling-rose. In .

Step 7: Secure the electrical box to the concrete wall. With the electrical box attached to the anchor bolts, the next step is to secure the box to the concrete wall. This step ensures the stability and durability of the installation. Follow these steps to properly secure the electrical box: Inspect the box to ensure it is properly aligned and . I have an electrical box that is set about 1/8" too deep in the wall so when the switchplate is installed the receptable plugs are sunken into the plate and recessed. . How to cope with an electrical box set too deep in the wall? Ask Question Asked 3 years, 4 months ago. Modified 3 years, . You also may need longer screws to go through the . The parking lot comes with an electrical box with a 50A hookup. Right now the box just has a face plate covering it up, but I presume the intention is for owners to install a NEMA 14-50 outlet on it. See attached picture for the box. My question is - does this look suitable to mount a Gen 2/3 Wall Connector on the front of?In other words, when can you just start drilling through a wall and when do you need to be worried about hitting electrical lines, plumbing, etc. drywall; . Lines that go up and down the wall will frequently be attached to the stud with . with 1/2" drywall and 3 1/2" stud walls, I should be OK if I don't drill more than 1 3/4" into the wall .

Drywall is not considered combustible but the gap behind the plate looks to expose the inner wall to a combustible area and possibly wood surfaces. Besides, it looks more professional to use a box extension rather than just monkey rigging it with nuts or plastic clips on a .It may also possibly be influenced by which muscle groups are effected (with Tazers, depending on which part of the body is hit, it can cause the body simply to go rigid, or to get thrown into the air from muscle contractions, or simply to collapse onto the floor - although Tazers are somewhat more specific in their actions than indiscriminate . Carefully cut the new box into a fresh bit of drywall, moving it in the direction from which the cable enters the area. This will give you more length to work with. Remove the cable from the old box and insert it into the new box. Install . A simple 2x6 horizontally across the stud bay is all that is needed, 2 screws from the back of the box into the 2x6. Remember if in the center and no clamps NMB needs to be stapled within 8” Make sure to set the back cross beam or horizontal box hanger so your box will protrude ~1/2” beyond the face of the stud I have seen DIY’s forget .

Sometimes they don't line up and you can't go back to back. Reactions: Easy, el dub, MikeFL and 1 other person. . Mounted the meter on one side with a little conduit stub right out the back and into the distro-panel. Actually thought it looked pretty clean and simple. . Back-to-back is the most common setup here by far, for decades; if the . Now 3M does say "When the moldable putty pad outlet box protective material is used as directed, the horizontal separation between outlet boxes on opposite sides of the wall may be less than 24" provided that the outlet boxes are not installed back to back

Custom Aluminum Parts. eMachineShop has machined aluminum parts for over 15 years. You can design and order your parts with our free CAD software or upload your own CAD file for a fast quote. FREE Shipping in the USA. No Minimum Order Quantity. 100% Quality Guaranteed.

how far back does electrical box go into wall|depth of electrical box installation