cnc machine vs human Machining can be described as conventional, which requires manual technician prompting and manipulation of the cutting tools, or non-conventional, such as CNC machining, which relies on computer automation . Sheet Metal Doors are stronger and provide better protection from quick raids. The strongest doors in the game are Garage Doors and Armored Doors, both of which require blueprints to learn or research through the tech tree.

0 · traditional machining vs cnc

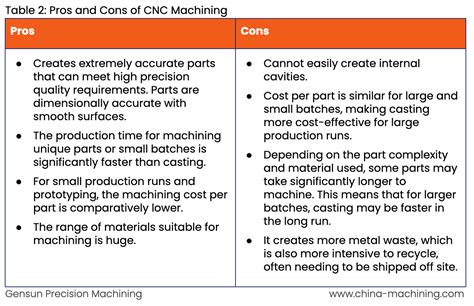

1 · pros and cons of cnc machines

2 · manual machining vs cnc machine

3 · difference between cnc and traditional

4 · difference between cnc and manual

5 · difference between cnc and conventional

6 · cnc vs manual machining cost

7 · are cnc machines accurate

Precision metal sheet fabrication is a refined process that focuses on the creation of highly accurate and detailed metal parts and assemblies. This method is crucial in industries where exact measurements and specifications .

traditional machining vs cnc

By replacing manual processes with computer numerical control, it offers precision, consistency, and efficiency that traditional methods can’t match. This article will explore the main benefits of CNC machining and why it might . Discover the superiority of CNC over manual machines with dekcel-cnc. Enhance precision and efficiency! Dive into our detailed comparison now! What is the Difference Between CNC Machines and Traditional Machines? CNC, or Computer Numerical Control machines, operate through automated digital instructions that control the machining process. This level of . With pre-programmed instructions, CNC machines can replicate the same parts repeatedly. This guarantees product quality and minimizes the waste that can arise from human error. Additionally, modern CNC machines .

Machining can be described as conventional, which requires manual technician prompting and manipulation of the cutting tools, or non-conventional, such as CNC machining, which relies on computer automation . Here are three CNC machines to discuss as you evaluate CNC machining vs Manual machining. CNC mill machine. CNC milling is a universal method used for complex parts manufacturing. It utilizes a rotating cylindrical .

d & a metal fabrication

A CNC machine is an automatic power tool with computer controlled for turning, milling, engraving, cutting, drilling, grinding, welding, spinning, winding in modern industrial manufacturing. . which reflects the humanization that .Understand the unique advantages of 3-axis, 4-axis, and 5-axis CNC machining for your projects. Learn how each configuration impacts precision, design complexity, and cost, with expert insights to help you select the ideal setup for applications from simple parts to intricate aerospace components. Find out more about the best uses and limitations of each CNC machining type . Manual V grooving machines often struggle to match the precision and consistency of CNC machines: Human Error: The manual operation introduces the potential for human error, which can lead to . CNC machines excel in intricate and sophisticated tasks, thanks to computer-controlled precision and repeatability. In contrast, a manual lathe provides more hands-on control and is well-suited for simpler projects and quick adjustments. . CNC machines require less human labor and maintenance compared to manual machining, resulting in long .

Precise control from CNC machines eliminates human error, ensuring each component meets exact specifications. Moreover, the ability to produce precision-turned components consistently gives businesses a competitive edge. Whether it’s a drill bit or a complex assembly, CNC machining ensures that each part is manufactured to perfection . Evaluating the Cost Differences of CNC and Manual Machining . CNC Machining and Its Cost Efficiency. CNC machining tends to be more efficient than manual machining, leading to lower labor costs.Automated CNC processes mean that operators can manage multiple machines, unlike manual CNC lathe or manual milling where continuous monitoring is .

Yes, CNC machining has a very higher accuracy than manual machines. A CNC machine can provide an accuracy on a microscopic level, which is not possible through manual machines due to human limitations of the latter. This is why CNC machining equipment such as the CNC mill is used where tolerances need to be kept to a minimum.Automation in CNC (Computer Numerical Control) machining refers to the integration of advanced technologies that enable machines to operate with minimal human intervention. This technology-driven approach is designed to enhance efficiency, productivity, and precision in . CNC machining vs manual machining is confused about which one to choose. This article is about all their differences, including principles, pros and cons. . Due to high dependency on human operators, manual machines lack precision, which means there is a higher possibility of human errors with this method. By following programmed instructions, CNC machines can efficiently fabricate complex geometries with minimal human intervention, making them integral to modern manufacturing industries.

CNC machines are utilized in many industries, and their use is increasing every year. The global CNC machine market is projected to grow from 83.99 billion USD in 2021 to 128.41 billion USD in 2028 – that’s over a 50% increase — and it’s primarily due to an increased demand for greater manufacturing efficiency and precision.

CNC machines play a pivotal role in the present-day scenario of flexible manufacturing. It is considered as a key contributing element towards the success of Industry 4.0 concept. In most of CNC machine failures, it has been observed that the main reasons behind their occurrence are from the operators’ end.

Each approach has its advantages and limitations, making it essential to understand the differences in CNC machining vs. traditional machining to determine which method best fits your operational needs. Understanding CNC Machining. CNC machining utilizes computerized systems to control machine tools, allowing for high precision and automation. This video shows how Omron's solution can transform a manufacturing line to be Industry 4.0 ready. It demonstrates traceability and work-in-progress trackin. CNC vs laser cutter in 3D/2D capabilities. A laser cutter is a 2D cutting machine. Even with a rotary attachment, they still only move in two directions. But, CNCs are 3D machines. CNC routers have three axes by .

pros and cons of cnc machines

You have certain machines – like CNC laser cutters – that deliver unrivaled accuracy and quality. Even a standard CNC milling machine is capable of better quality when compared to a similar traditional machine. There is no reliance on a human being to outline where a tool needs to go or what needs to be cut. The conventional machining process uses a human operator to direct and control machining tools such as milling, boring, and drilling machines as well as lathes and other sharp cutting tools. This individual is responsible for driving the location and intensity of tool contact with the raw material through the use of buttons, levers, or wheels .

To alleviate CNC machine failure due to human errors, the managers should focus on the cause group errors, i.e. poor vigilance, poor skillset and lack of knowledge of the operator. Download: Download high-res image (126KB) Download: Download full-size image; Fig. 2. CNC Machining Vs Manual Machining- Advantages And Disadvantages. . Human errors can result in inconsistencies, making it challenging to attain the same level of precision as that achieved through CNC machining. . However, CNC machines offer higher precision, automation, and the ability to handle complex designs and multi-axis operations .While conventional machining can produce high-quality results, it lacks the efficiency and speed necessary for large production runs. In contrast, CNC machining can deliver consistent parts at scale and meet tight deadlines. The key difference is that CNC machines are controlled by software, rather than human operators. Multi-Tasking CNC Machines. Modern CNC grinding machines are increasingly designed to perform multiple tasks in a single setup, reducing the need for multiple machines and setups. These multi-tasking machines can combine grinding with other machining processes such as milling, drilling, and turning, enhancing versatility and productivity.

CNC Lathe Machining vs. Manual Machining: A Detailed Comparison Precision and Accuracy. CNC lathe machining offers superior precision, making it the preferred choice for industries where tight tolerances are crucial. Once a CNC machine is programmed, it can consistently produce identical parts with minimal variation.Advantages of CNC Machining. High Precision and Repeatability: CNC machines produce parts with exceptional accuracy, meeting stringent industry standards. Reduced Human Error: Minimizing manual intervention reduces the risk of errors and inconsistencies. 24/7 Operation: CNC machines can run continuously, increasing production capacity.

Robots vs CNC Machines. Industrial robots and CNC machines were both introduced to manufacturing around the same time during the 1960s. Both have been deployed to automate production lines in order to reduce the amount of human involvement with manufacturing processes for more efficient operations.

CNC Automation Is Meant to Make Manual Labor Easier for Humans. At its very core, automation was developed in order to assist humans—to ease the load of having to do actions that are extremely repetitive and mundane. Robots make the workplace more efficient in order for the human workforce to focus on tasks that offer more value to the .

manual machining vs cnc machine

difference between cnc and traditional

K Factor in sheet metal bending is a constant used to calculate sheet metal flat length or Flat-pattern. Mathematically k factor value is equal to the ratio of position of the .

cnc machine vs human|traditional machining vs cnc