advantages of part line programing cnc Are you new to the Machining industry or considering a career in this field

At Lowe’s, we carry a range of fence parts that includes accessories for wood, vinyl and chain link fences. Powder-coated steel U-posts offer a durable design and serve as the foundation for rolled fences. These posts resist corrosion and chipping and are easy to install, with no digging required.

0 · what is cnc programming

1 · manual cnc programming vs manual

2 · cnc programming tools

3 · cnc machine programming process

4 · cnc machine programming instructions

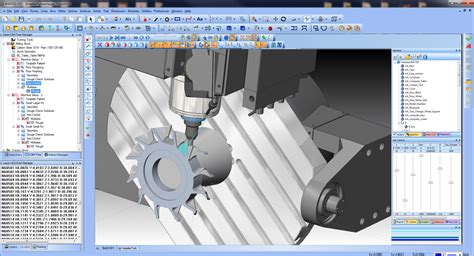

5 · cam software vs cnc programming

6 · basics of cnc programming

7 · basic cnc machine programming

$6.59

Manual programming is limitless when it comes to developing a part program. You can set and adjust every fine detail to your exact touch, whether it’s tweaking feeds and speeds, changing cycle parameters, or using different cycles. Another big advantage is that manual .Manual programming for a CNC mill or lathe has been the most common way . CNC .

For you to get a job as a CNC Machinist, you will need to . Job 0. CNC Machinist .

how to use a multimeter to test a junction box

This website uses cookies to ensure you get the best experience on our website. .CNC Machinist Training – How to Become A Machinist. CNC machining and other .Are you new to the Machining industry or considering a career in this fieldThere are a lot of tools that a CNC Machinist will use over the

CNC machine programming offers numerous advantages over traditional manual machining techniques. It improves efficiency, accuracy, and productivity, reduces human error, and .

what is cnc programming

Here are a few of the pros and cons of the different approaches: Efficiency: CAM software automates much of the CNC programming process. It can often take only a few minutes to generate a complete CNC program. This . When selecting your CNC machine, it’s especially important to consider the control and operating system and how that might aid or impede automation and programming. In .

CNC programming refers to the process of using software to develop CNC machine instructions. These instructions control how the CNC machine moves while interacting with the work piece. Popular CNC machines . CNC programming provides automation, cost savings, excellent machining quality, flexibility, reduced production time, and a host of other benefits to manufacturers. It is an incredibly versatile industrial solution that can be .

There are several significant benefits. In theory, a good CNC program should result in a good part every time. A CNC mill will remove the same amount of material, a lathe will turn a part at a .

CNC programming advantages for fewer operating expenses and high profit that helps businesses to expand. CNC programming controls routers, mills, lathes, mill-turn and turn-mill machines, multi-tasking centers, wire . Unlock the true potential of your CNC machining operations with automated part programming techniques at Premier Equipment Inc. Learn how automation can revolutionize .

Manual programming is limitless when it comes to developing a part program. You can set and adjust every fine detail to your exact touch, whether it’s tweaking feeds and speeds, changing cycle parameters, or using different cycles. Another big advantage is that manual programming teaches strong discipline.

CNC machine programming offers numerous advantages over traditional manual machining techniques. It improves efficiency, accuracy, and productivity, reduces human error, and allows for complex and intricate designs to be produced with ease. Here are a few of the pros and cons of the different approaches: Efficiency: CAM software automates much of the CNC programming process. It can often take only a few minutes to generate a complete CNC program. This saves time and increases efficiency. When selecting your CNC machine, it’s especially important to consider the control and operating system and how that might aid or impede automation and programming. In many cases, selecting an option with conversational programming can be a game changer.

Conversational programming allows your operators to easily generate programs on a CNC machine control in a matter of minutes, with a series of built-in data prompts involving part geometry, work piece material, and tooling to guide operators through the machining process. CNC programming refers to the process of using software to develop CNC machine instructions. These instructions control how the CNC machine moves while interacting with the work piece. Popular CNC machines that work with CNC programming are CNC lathes and CNC milling machines.

how to use a metal box of wood chip smoker

CNC programming provides automation, cost savings, excellent machining quality, flexibility, reduced production time, and a host of other benefits to manufacturers. It is an incredibly versatile industrial solution that can be used with wood, metal, plastics, composites, glass, foam, and more.There are several significant benefits. In theory, a good CNC program should result in a good part every time. A CNC mill will remove the same amount of material, a lathe will turn a part at a given speed – with CNC, a given program is nearly infinitely repeatable. For a manufacturer, this means that an entire run of parts should be consistent. CNC programming advantages for fewer operating expenses and high profit that helps businesses to expand. CNC programming controls routers, mills, lathes, mill-turn and turn-mill machines, multi-tasking centers, wire EDMs, and industrial robots. Unlock the true potential of your CNC machining operations with automated part programming techniques at Premier Equipment Inc. Learn how automation can revolutionize your workflow, enhance efficiency, and ensure optimal precision in Mazak machining. Explore the benefits of automation and drive your business towards unprecedented productivity. Don't .

Manual programming is limitless when it comes to developing a part program. You can set and adjust every fine detail to your exact touch, whether it’s tweaking feeds and speeds, changing cycle parameters, or using different cycles. Another big advantage is that manual programming teaches strong discipline.CNC machine programming offers numerous advantages over traditional manual machining techniques. It improves efficiency, accuracy, and productivity, reduces human error, and allows for complex and intricate designs to be produced with ease.

manual cnc programming vs manual

cnc programming tools

Here are a few of the pros and cons of the different approaches: Efficiency: CAM software automates much of the CNC programming process. It can often take only a few minutes to generate a complete CNC program. This saves time and increases efficiency. When selecting your CNC machine, it’s especially important to consider the control and operating system and how that might aid or impede automation and programming. In many cases, selecting an option with conversational programming can be a game changer. Conversational programming allows your operators to easily generate programs on a CNC machine control in a matter of minutes, with a series of built-in data prompts involving part geometry, work piece material, and tooling to guide operators through the machining process. CNC programming refers to the process of using software to develop CNC machine instructions. These instructions control how the CNC machine moves while interacting with the work piece. Popular CNC machines that work with CNC programming are CNC lathes and CNC milling machines.

how to test jet ski electric box

CNC programming provides automation, cost savings, excellent machining quality, flexibility, reduced production time, and a host of other benefits to manufacturers. It is an incredibly versatile industrial solution that can be used with wood, metal, plastics, composites, glass, foam, and more.There are several significant benefits. In theory, a good CNC program should result in a good part every time. A CNC mill will remove the same amount of material, a lathe will turn a part at a given speed – with CNC, a given program is nearly infinitely repeatable. For a manufacturer, this means that an entire run of parts should be consistent. CNC programming advantages for fewer operating expenses and high profit that helps businesses to expand. CNC programming controls routers, mills, lathes, mill-turn and turn-mill machines, multi-tasking centers, wire EDMs, and industrial robots.

cnc machine programming process

Best CNC Router Overall: MYSWEETY CNC Pro Engraver Machine Shop Now Runner Up: SainSmart Genmitsu CNC Router Machine Shop Now Honorable Mention: .

advantages of part line programing cnc|manual cnc programming vs manual