7 axis cnc machine working video A 7 Axis CNC machine is a type of computer numerical control machine that has seven axes of motion. It is capable of performing complex and precise machining operations on a variety of materials such as metals, .

Reliable milling spindles, powerful motors, innovative cooling systems and tool systems in all common sizes, including fast changers for the milling tools, are what characterize DMG MORI vertical machining centers – paired with the stable construction of the machines.

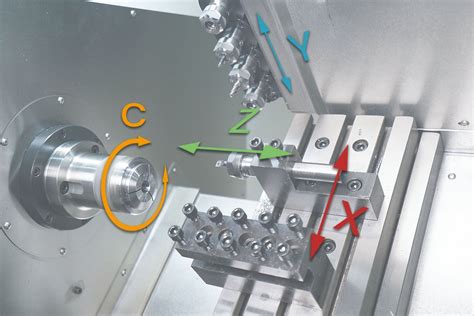

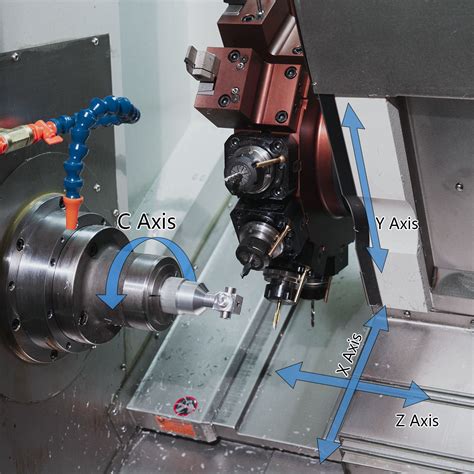

0 · y axis cnc lathe

1 · lathe axis explained

2 · cnc xyz axis

3 · cnc machine axis locations diagram

4 · axis identification in cnc machine

5 · 7 axis robot arm cnc

6 · 7 axis machining center

7 · 7 axis cnc machine price

Designed to house and protect a wide range of equipment, Altelix Industrial NEMA rated enclosures include options such as cooling and heating, FRP, ABS or Steel construction and in multiple sizes and configurations. In addition to our standard enclosures, full customization is .

Contact us cnc programmer: [email protected]://cmj.citizen.co.jp/english/product/cincom/cincom_l32.html For more information contact Global Equipment Group - U.S. and Canad representatives for Omag. Call 855-456-2588 or email [email protected].

7-axis CNC machining is used to produce intricate parts like engine components, transmission parts, and custom car parts. This technology allows manufacturers to reduce the number of . CNC Programmer Peter Chase discusses the entire Set Up and Process including how he uses Autodesk PowerMILL to program his Amazing 7 Axis Robot. .more. Learn about the Amazing 7 Axis. 7 axis CNC machining means that the machine can handle 7 operations to machine parts in one process, including the X, Y, and Z operations in standard CNC machining. It also . A 7 Axis CNC machine is a type of computer numerical control machine that has seven axes of motion. It is capable of performing complex and precise machining operations on a variety of materials such as metals, .

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the .

CNC Machine Video Gallery. A collection of videos including tips & trics, webinars, and training that will help you learn to program on the Hurco WinMax conversational control.

What is 7-axis CNC Machining? 7-axis CNC machining follows the same principle as 5-axis CNC machining with the addition of two more axes, making it a more versatile CNC machining technology. It usually includes: X . Contact us cnc programmer: [email protected]://cmj.citizen.co.jp/english/product/cincom/cincom_l32.htmlFor more information contact Global Equipment Group - U.S. and Canad representatives for Omag. Call 855-456-2588 or email [email protected].

And manufacturers can design and program the parts with any CAD, CAM software, and generate g-codes to feed into the CNC machine. Here’s is a video of a 7-axis CNC milling and turning center in action that features complete machining of a part from scratch.7-axis CNC machining is used to produce intricate parts like engine components, transmission parts, and custom car parts. This technology allows manufacturers to reduce the number of setups needed, cutting down on production time and costs.

CNC Programmer Peter Chase discusses the entire Set Up and Process including how he uses Autodesk PowerMILL to program his Amazing 7 Axis Robot. .more. Learn about the Amazing 7 Axis.

7 axis CNC machining means that the machine can handle 7 operations to machine parts in one process, including the X, Y, and Z operations in standard CNC machining. It also includes rotational axes such as Yaw, Pitch, and Rotation. A 7 Axis CNC machine is a type of computer numerical control machine that has seven axes of motion. It is capable of performing complex and precise machining operations on a variety of materials such as metals, plastics, and composites.

In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.CNC Machine Video Gallery. A collection of videos including tips & trics, webinars, and training that will help you learn to program on the Hurco WinMax conversational control.

What is 7-axis CNC Machining? 7-axis CNC machining follows the same principle as 5-axis CNC machining with the addition of two more axes, making it a more versatile CNC machining technology. It usually includes: X axis for vertical rotation; Y axis for horizontal rotation; Z axis for depth of the part; A axis for X axis revolution Contact us cnc programmer: [email protected]://cmj.citizen.co.jp/english/product/cincom/cincom_l32.html

y axis cnc lathe

For more information contact Global Equipment Group - U.S. and Canad representatives for Omag. Call 855-456-2588 or email [email protected] manufacturers can design and program the parts with any CAD, CAM software, and generate g-codes to feed into the CNC machine. Here’s is a video of a 7-axis CNC milling and turning center in action that features complete machining of a part from scratch.7-axis CNC machining is used to produce intricate parts like engine components, transmission parts, and custom car parts. This technology allows manufacturers to reduce the number of setups needed, cutting down on production time and costs. CNC Programmer Peter Chase discusses the entire Set Up and Process including how he uses Autodesk PowerMILL to program his Amazing 7 Axis Robot. .more. Learn about the Amazing 7 Axis.

7 axis CNC machining means that the machine can handle 7 operations to machine parts in one process, including the X, Y, and Z operations in standard CNC machining. It also includes rotational axes such as Yaw, Pitch, and Rotation. A 7 Axis CNC machine is a type of computer numerical control machine that has seven axes of motion. It is capable of performing complex and precise machining operations on a variety of materials such as metals, plastics, and composites.In this article, we’ll compare the functions and capabilities of various multi-axis CNC milling machines. 3-axis CNC machining evolved from rotary filing (think dental drill 😬). With a 3-axis CNC machine, the workpiece is stationary while the cutting tool moves across the X-, Y-, and Z-axes.CNC Machine Video Gallery. A collection of videos including tips & trics, webinars, and training that will help you learn to program on the Hurco WinMax conversational control.

metal pipe enclosures

metal planter boxes modern

Underneath the mount is also one of two options for Di2 junction box location (click to enlarge). Other highlights include lightweight FACT 11r carbon frame and Rider-First Engineering in order to provide consistent performance across the entire size range, which includes six frame sizes from 49cm to 61cm.

7 axis cnc machine working video|cnc machine axis locations diagram