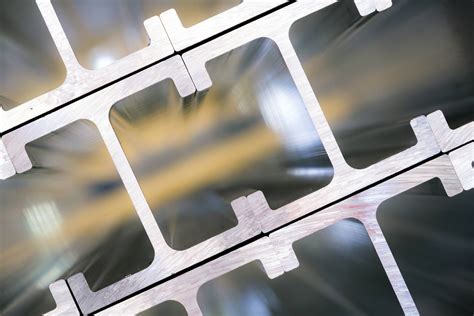

7075 cnc aluminum machining 7075 Aluminum is known for its high strength. Its tensile strength is 570MPa. It also has good fatigue strength and machining properties. But it is heat treatable which improves its all the other properties. It can process thorough forging, rolling, extrusion, drawing and can be in powder, bars, and plates forms.

The finished CNC machined parts are carefully packaged to protect them during shipping. They are then delivered to the customer or to the next stage of the manufacturing process. Common CNC machining process methods. Milling: Milling is one of the most commonly used CNC machining methods. It removes material from the workpiece by rotating the .

0 · how strong is 7075 aluminum

1 · how is 7075 aluminum made

2 · aluminum 7075 mechanical properties

3 · 7075 vs 6061 aluminum cost

4 · 7075 t6 aluminum vs 6061

5 · 7075 aluminum corrosion resistance

6 · 7075 aluminum compared to 6061

7 · 6061 vs 7075 aluminum strength

review four major enclosure options (ODP, WPII, TEWAC and TEAAC) for large- and medium-size electric motors (3,000 horsepower [hp] or larger) and a guide for selecting proper motor .

Despite its favorable properties, cnc machining Aluminum 7075 presents unique challenges: Tool Wear: High strength can accelerate tool wear. Burr Formation: Tendency to form burrs during cutting. Surface Finish: Achieving a smooth .

For complex geometries, 7075 aluminum can also be successfully processed using CNC machining, which enables high precision and good repeatability. In some instances, electrical discharge machining(EDM)may be a non-traditional method to .Despite its favorable properties, cnc machining Aluminum 7075 presents unique challenges: Tool Wear: High strength can accelerate tool wear. Burr Formation: Tendency to form burrs during cutting. Surface Finish: Achieving a smooth surface finish requires precise control of . 7075 aluminum alloy is a cold-treated forging alloy with high strength, far better than soft steel. 7075 is one of the most powerful alloys for commercial use. 7075 aluminum alloy has a tight structure and strong corrosion resistance and is best for aviation and marine plates.Aluminium 7075(AlZnMgCu1,5):Cutting conditions, Recommended Carbide Grades, Equivalent Material Standards, and Chemical Composition

7075 Aluminum is known for its high strength. Its tensile strength is 570MPa. It also has good fatigue strength and machining properties. But it is heat treatable which improves its all the other properties. It can process thorough forging, rolling, extrusion, drawing and can be in powder, bars, and plates forms.

how strong is 7075 aluminum

how is 7075 aluminum made

Aluminum 7075-T651 (CNC) is an aerospace-grade material with excellent strength-to-weight ratio and strength and hardness comparable to steels. T651 is the temper of Aluminum 7075, and to achieve this temper, the alloy is solution heat-treated, stress relieved, and then artificially aged.Fictiv offers multiple aluminum alloys. Our standard alloy on platform is 6061, a versatile and easy-to-machine metal. It is corrosion-resistant, non-magnetic, and heat treatable. 7075 Aluminum is a hard, high strength alternative to 6061 Aluminum .Cox Manufacturing has a reputation for machining quality parts & high volume swiss screw machining from Aluminum alloy 7075. We can machine intricate parts on our CNC Swiss machines and CNC turning centers .Aluminum 7075 Machining D.W. Ram specializes in the production of aluminum 7075 machined parts with tight tolerances and complex geometries. We combine decades of expertise with innovative CNC machining techniques to meet client needs on time and within budget.

Machining aluminum parts is easy with our free CAD design software, instant quoting and online ordering for prototypes or production. For complex geometries, 7075 aluminum can also be successfully processed using CNC machining, which enables high precision and good repeatability. In some instances, electrical discharge machining(EDM)may be a non-traditional method to .Despite its favorable properties, cnc machining Aluminum 7075 presents unique challenges: Tool Wear: High strength can accelerate tool wear. Burr Formation: Tendency to form burrs during cutting. Surface Finish: Achieving a smooth surface finish requires precise control of .

7075 aluminum alloy is a cold-treated forging alloy with high strength, far better than soft steel. 7075 is one of the most powerful alloys for commercial use. 7075 aluminum alloy has a tight structure and strong corrosion resistance and is best for aviation and marine plates.Aluminium 7075(AlZnMgCu1,5):Cutting conditions, Recommended Carbide Grades, Equivalent Material Standards, and Chemical Composition

aluminum 7075 mechanical properties

7075 Aluminum is known for its high strength. Its tensile strength is 570MPa. It also has good fatigue strength and machining properties. But it is heat treatable which improves its all the other properties. It can process thorough forging, rolling, extrusion, drawing and can be in powder, bars, and plates forms.Aluminum 7075-T651 (CNC) is an aerospace-grade material with excellent strength-to-weight ratio and strength and hardness comparable to steels. T651 is the temper of Aluminum 7075, and to achieve this temper, the alloy is solution heat-treated, stress relieved, and then artificially aged.

Fictiv offers multiple aluminum alloys. Our standard alloy on platform is 6061, a versatile and easy-to-machine metal. It is corrosion-resistant, non-magnetic, and heat treatable. 7075 Aluminum is a hard, high strength alternative to 6061 Aluminum .Cox Manufacturing has a reputation for machining quality parts & high volume swiss screw machining from Aluminum alloy 7075. We can machine intricate parts on our CNC Swiss machines and CNC turning centers .Aluminum 7075 Machining D.W. Ram specializes in the production of aluminum 7075 machined parts with tight tolerances and complex geometries. We combine decades of expertise with innovative CNC machining techniques to meet client needs on time and within budget.

unique steel lunch box

7075 vs 6061 aluminum cost

Outdoor electrical boxes are commonly used for installing outdoor outlets, light fixtures, security cameras, and other electrical devices in patios, decks, gardens, or other outdoor spaces.

7075 cnc aluminum machining|7075 vs 6061 aluminum cost