sheet metal forming tool design Dimple forming has been a vital tool in metalworking since the early 1900s, significantly impacting industries like automotive and aerospace by enhancing the structural integrity and aesthetics of sheet metal components. In this article, we’ll explore the history, applications, and benefits of sheet metal dimple dies, along with practical tips for using them .

$36.99

0 · solidworks sheet metal stamping

1 · sheet metal forming solidworks

2 · sheet metal forming hand tools

3 · sheet metal forming by hand

4 · sheet metal fabricating tools

5 · forming tool sheet metal solidworks

6 · custom tooling for metal forming

7 · custom sheet metal forming

The TOPGREENER TGWFRSM1 Wi-Fi single relay module is designed for installation behind light switches, electrical outlets, or inside ceiling boxes. Instantly upgrade any appliance into a remote-controlled smart device.

Objectives. By the end of today you should be able to. .describe different forming processes, when they might be used, and compare their production rates, costs and environmental . Sheet metal forming technology has undergone a significant transformation in recent years, driven by advancements in materials, processes, and design tools. Today, engineers and designers have access to a vast array of innovative techniques that enable them to create complex and intricate sheet metal parts with unprecedented precision and . To ensure your tool creates the quality form consistently and reliably, we need the following information: Machine Make and Model; Material Type and Thickness; Form Up or Form Down – Wilson Tool always . The side of the metal sheet facing the forming tool is used as the contact surface for moulding process. Thus, thickness variation on the sheet metal does not cause major influence on the moulded part influencing only the tool mechanical behaviour. . The design of a sheet metal tool is strongly dependent on the manufacturing process where it .

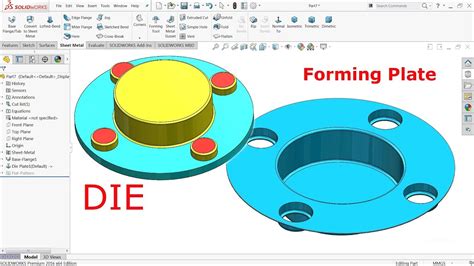

Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part . Dimple forming has been a vital tool in metalworking since the early 1900s, significantly impacting industries like automotive and aerospace by enhancing the structural integrity and aesthetics of sheet metal components. In this article, we’ll explore the history, applications, and benefits of sheet metal dimple dies, along with practical tips for using them .Contents. Creating Forming Tools. You can create forming tool parts for use in sheet metal parts. Applying Forming Tools to Sheet Metal Parts. Forming tools from the Design Library are used only with sheet metal parts. Sheet metal parts display the Sheet-Metal feature in .Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part files (*.SLDPRT), not Form Tool (*.SLDFTP) files.

Click the forming tool on the sheet metal toolbar, select stopping face, select faces to remove and click ok. I took this straight out of the help files. Try doing some research before asking the question. Solid works has great tutorials on how to form dimples and such in sheet metal with solid bodies. I can't find anything in Inventor Help, youtube or. . Forming sheet metal features with solid Bodies in Inventor . The process for creating Punch Tools (Form Tools) is significantly different in Inventor than SolidWorks. . In this video we are going to learn how to make the punch and die by using sheet metal partOpen a sheet metal part, and browse to the forming tools folder in the Design Library.; Right-click the folder and click Forming Tools Folder.If Forming Tools Folder is already selected, omit this step. When asked if you want all subfolders to be marked as forming tools folders, click Yes.

In this video we are going to learn how to design the punch and die in NX software In conclusion, understanding the basics of sheet metal fabrication and the process involved in forming and laser cutting are crucial steps in creating effective designs.By adhering to these sheet metal design guidelines, engineers and designers can successfully navigate the process of turning raw sheets into valuable components.A Lance and Form is a tool that both cuts (lances) and forms sheet metal. They are a great tool for a variety of applications, including air flow, decoration, card guides, location markers, shear tabs, wire harnesses and clip attachments. With Wilson Tool’s adjusting spring plunger, you can make length adjustments without shims.

I can't seem to find the forming tools in the design library. I need to put a form in the bottom of this sheet metal but can't find the forming tools in the design library.

solidworks sheet metal stamping

Before you apply forming tools to sheet metal parts, in the Design Library you must right-click the folder that contains the forming tools and select Forming Tools Folder to designate its contents as forming tools. This applies to forming tools that are part .Andersson: Comparison of Sheet Metal Forming Simulation and Try-out Tools in Design of Forming Tools, J. of Engineering Design, v. 15. (2004) No. 6. pp. 551-561. [19] However, the process of tool design and material selection is beyond the scope of this review, and interested readers are referred to . Firat, M. (2007b). Computer aided analysis and design of sheet metal forming processes:: Part III: Stamping die-face design. Materials and Design, 28, 1311–1320.

In this section You will learn the basics of Sheet metal design command in NX : Sketch - It is the basics of any design. • Extrude - It creates a feature by extruding a section along a vector. • Sheet Metal from solid - It builds a sheet metal model that takes its shapes from a .Open a sheet metal part, and browse to the forming tools folder in the Design Library.; Right-click the folder and click Forming Tools Folder.If Forming Tools Folder is already selected, omit this step. When asked if you want all subfolders to be marked as forming tools folders, click Yes.A Standard Style Louver Punched Into Sheet Metal Forming of Louvers Punch Press. Forming a louver on a punch pres is by far the easiest method, though it requires large and expensive tooling. If you are designing a piece which uses many louvers, it is certainly desirable to have it manufactured on a punch press over a press brake.Forming tools from the Design Library are used only with sheet metal parts. Sheet metal parts display the Sheet-Metal feature in the FeatureManager design tree. . If the forming tool has radii that are pushed into the sheet metal body, then the forming tool will fail when the concave radius is smaller than the material thickness. In this case .

The forming simulation in sheet metal forming technology and its industrial applications have greatly impacted the automotive sheet metal product design, die developments, die construction and . Design hubthis video about How to Design forming tool in Solidworks. at the last of video you will be able to make and Design Today, the accuracy of the results in sheet-metal-forming simulation is high enough to replace the use of try-out tools to a great extent. At Volvo Car Corporation, Body Components, where this study has been carried out, sheet-metal-forming simulation is used as an integrated part in the process of tool design and tool production. 6. TOOL DESIGN PROCEDURE STUDY OF COMPONENT The first step in the design procedure is to define the problem in a clear and simple statement of the functional needs. The tool design will receive the part print, information on which tool is needed, what the capabilities of the tool must be, the type of the press on which tool is used, the number of parts .

Sheet metal design skills are a crucial tool in any engineer’s toolbox, but given how little attention sheet metal design gets in academia, most skills are learned on the job. . A basic (single axis) bend is the most foundational sheet metal forming operation. Despite the relative simplicity of the bending process, there is a lot to .

sheet metal forming solidworks

sheet metal forming hand tools

sheet metal forming by hand

Steelscapes Rustics capture the natural beauty of oxidized metal while offering finish warranties of up to 30 years. From the fresh oxidized glow of Sedona Rust to the aged tone of Natural Rust, Steelscape has an authentic finish for all applications.In this guide o how to glue fiberglass to metal, you will learn step-by-step how to prepare the surfaces, apply the glue, and cure the bond to full strength. The top choices for gluing fiberglass to metal will include epoxy resin, polyurethane .

sheet metal forming tool design|sheet metal forming by hand