coolant in cnc machines Using water alone as a coolant is never a good idea since it’s the additives in the fluid that prevent damaging rust and corrosion. Typically, most CNC machine tools use one of the following types of coolant classified as follows: See more uxcell 7.9"x4.7"x2.2"(200mmx120mmx56mm) ABS Junction Box Universal Project Enclosure W PC Transparent Cover light Gray Visit the uxcell Store 4.5 4.5 out of 5 stars 137 ratings

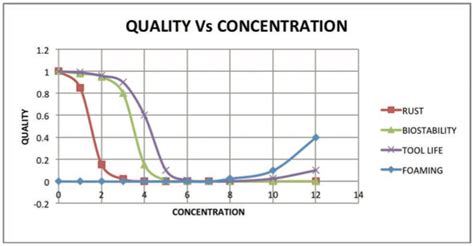

0 · machine coolant concentration chart

1 · coolant tank for cnc machine

2 · coolant system for milling machine

3 · coolant mixers for cnc equipment

4 · coolant concentration for cnc machines

5 · cnc machine coolant suppliers

6 · best semi synthetic machine coolant

7 · best coolant for cnc machine

Recognized as a trusted metal panel across multiple industries, 5V Crimp holds strong and provides a profitable outcome with a low margin. These panels stand as one of the favored options with high quality and low maintainability. .

The terms “coolant” and “lubricant” are often used interchangeably, but not all coolants are lubricants. For example, compressed air works as a coolant but has no use as a lubricant. No matter what type of CNC machining you do, CNC coolants play a Critical Role They help increase tool life and offer a better . See moreUsing water alone as a coolant is never a good idea since it’s the additives in the fluid that prevent damaging rust and corrosion. Typically, most CNC machine tools use one of the following types of coolant classified as follows: See more

Using the correct coolant for the material and type of machining results in higher production efficiency and sustained high-quality products. Recommendations vary according to the manufacturer, but for a general idea of different coolants used for other materials and . See moreMost machine manufacturers provide explicit instructions on the type of coolant their machine requires. For instance, manufacturers of . See moreApplying a water-soluble cutting fluid is as vital as the type you use. Most CNC lathes and machining centers come with through-the-tool coolant capability, and it makes sense to use it, even if you must buy new tool holders. If your machine tool can use high-pressure . See more Explore the crucial role of coolant in CNC machining operations, understanding how it dissipates heat, lubricates, and prevents tool wear. .

No matter what type of CNC machining you do, CNC coolants play a critical role. They help increase tool life and offer a better surface finish on the machined parts. By understanding the available coolant types, you can select a .

Explore the crucial role of coolant in CNC machining operations, understanding how it dissipates heat, lubricates, and prevents tool wear. Learn about coolant types, formulations, and why consistent application is essential for optimal machining outcomes. The significance of coolant in CNC machining cannot be overstated. By selecting the appropriate coolant type and managing it properly, manufacturers can extend tool life, improve surface finishes, and optimize overall machining efficiency.

Here, we’ll address this by breaking down the functions of coolant, the importance of choosing the right one for your CNC machine, and delve deeper into one of the popular types – soluble oils. Understanding the Role of Coolant in CNC Machining

The selection, monitoring, and maintenance of CNC machining coolant are crucial for maintaining temperature control, chip evacuation, lubrication, and extending tool life. Read on to learn more about the different types of CNC machining coolants, their specific uses, and why they’re necessary to ensure precision in the machining process.

CNC coolant is a specially formulated fluid used in CNC machining processes to cool and lubricate the cutting tool and the workpiece during metal removal operations. CNC coolants are essential for dissipating heat generated by friction, ensuring smooth cuts, and preventing wear on both the tool and the machined surface.The selection, monitoring, and maintenance of CNC machining coolant are crucial for maintaining temperature control, chip evacuation, lubrication, and extending tool life. Read on to learn more about the different types of CNC machining coolants, their specific uses, and why they’re necessary to ensure precision in the machining process.

Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid chip removal. This article discusses how CNC coolant works, and its delivery technique. Coolant in purpose is widely understood – it’s used to temper high temperatures common during machining, and aid in chip evacuation. However, there are several types and styles, each with its own benefits and drawbacks.

Coolant is typically supplied at high pressure and volume straight to the chip-tool contact in a metal cutting process, with valves surrounding the machine to confine the splash and others to reach the filter and recirculate the fluid. The probability of flooding is reducing as technology improves. No matter what type of CNC machining you do, CNC coolants play a critical role. They help increase tool life and offer a better surface finish on the machined parts. By understanding the available coolant types, you can select a .

Explore the crucial role of coolant in CNC machining operations, understanding how it dissipates heat, lubricates, and prevents tool wear. Learn about coolant types, formulations, and why consistent application is essential for optimal machining outcomes. The significance of coolant in CNC machining cannot be overstated. By selecting the appropriate coolant type and managing it properly, manufacturers can extend tool life, improve surface finishes, and optimize overall machining efficiency. Here, we’ll address this by breaking down the functions of coolant, the importance of choosing the right one for your CNC machine, and delve deeper into one of the popular types – soluble oils. Understanding the Role of Coolant in CNC Machining

The selection, monitoring, and maintenance of CNC machining coolant are crucial for maintaining temperature control, chip evacuation, lubrication, and extending tool life. Read on to learn more about the different types of CNC machining coolants, their specific uses, and why they’re necessary to ensure precision in the machining process.

CNC coolant is a specially formulated fluid used in CNC machining processes to cool and lubricate the cutting tool and the workpiece during metal removal operations. CNC coolants are essential for dissipating heat generated by friction, ensuring smooth cuts, and preventing wear on both the tool and the machined surface.The selection, monitoring, and maintenance of CNC machining coolant are crucial for maintaining temperature control, chip evacuation, lubrication, and extending tool life. Read on to learn more about the different types of CNC machining coolants, their specific uses, and why they’re necessary to ensure precision in the machining process.

Machinists often utilize CNC machine coolant to mitigate the effects of overheating on the cutting tool or materials during the CNC machining process. These coolants are effective as lubricants and cooling mechanisms and aid chip removal. This article discusses how CNC coolant works, and its delivery technique. Coolant in purpose is widely understood – it’s used to temper high temperatures common during machining, and aid in chip evacuation. However, there are several types and styles, each with its own benefits and drawbacks.

machine coolant concentration chart

coolant tank for cnc machine

Find many great new & used options and get the best deals for Vintage USQMC NE & S Co 1948 18"x14.5"x10" Metal Storage Box at the best online prices at eBay! Free shipping for many products!

coolant in cnc machines|coolant tank for cnc machine