cnc machine numerical control Motion is controlling multiple axes, normally at least two (X and Y), and a tool spindle that moves in the Z (depth). The position of the tool is driven by direct-drive stepper motors or servo motors to provide highly accurate . See more © 2024 Von Metal Fabrications Ltd. All Rights Reserved. Theme By: RoseCityGardens.

0 · who invented cnc machine

1 · what is a cnc mill

2 · numerically controlled machine tool

3 · computerized numerical control cnc

4 · computer numerically controlled machine tools

5 · computer numerical control today

6 · computer numerical control cnc programmer

7 · cnc machine full form

Whether in a junction box or distribution box, WAGO's installation terminal blocks and connectors offer you the right product for every installation job. Push-in termination of solid conductors, such as that offered by our junction box connectors, saves you plenty of time and money.

In machining, numerical control, also called computer numerical control (CNC), is the automated control of tools by means of a computer. It is used to operate tools such as drills, lathes, mills, grinders, routers and 3D printers. CNC transforms a piece of material (metal, plastic, wood, ceramic, stone, or composite) . See more

Motion is controlling multiple axes, normally at least two (X and Y), and a tool spindle that moves in the Z (depth). The position of the tool is driven by direct-drive stepper motors or servo motors to provide highly accurate . See more

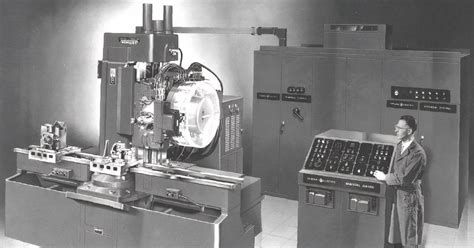

The first CNC machines were built in the 1940s and 1950s, based on existing tools that were modified with motors that moved the tool or part to follow points fed into the system on See more

Many other tools have CNC variants, including:• 3D printing• See more

Within the numerical systems of CNC programming, the code generator can assume that the controlled mechanism is always perfectly . See more

Now the CNC in the processing manufacturing field has been very extensive, not only the traditional milling and turning, other machines and equipment are also installed with the corresponding CNC, which makes the manufacturing . See moreIn CNC, a "crash" occurs when the machine moves in such a way that is harmful to the machine, tools, or parts being machined, . See moreIn numerical control systems, the position of the tool is defined by a set of instructions called the part program. Positioning control is handled using either an open-loop or a closed-loop system. In an open-loop system, communication takes place in one . See more What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, .

Computer numerical control (CNC) is a manufacturing method that automates the control, movement and precision of machine tools through the use of preprogrammed computer software, which is embedded inside the tools. CNC . CNC stands for Computer Numerical Control and is used to automate machine tools in manufacturing processes. CNC machines are programmed with G-code, a set of computer instructions that control their .The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how .

Computer Numerical Control, commonly written as CNC, is a type of control system that can provide automated movement and working of the machine tool. The instructions in CNC technology are written in a code format.computer numerical control (CNC), in manufacturing, the control of a device, particularly machine tools, by direct input of data from a computer program. It is a principal element of computer . Numerical control (NC), commonly known as computer numerical control (CNC), is a technology that allows the automation of machine tools. It uses programmable machine controller units and software to efficiently produce . CNC, or computer numerical control, automates machining with computer-guided tools for a precise, repeatable manufacturing process.

Today, computer numerical control (CNC) machines are found almost everywhere, from small job shops in rural communities to Fortune 500 companies in large urban areas. Truly, there is hardly a facet of manufacturing .

1968 vw bus sheet metal

In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] It is used to operate tools such as drills , lathes , mills , grinders , routers and 3D printers .

What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines : There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.Computer numerical control (CNC) is a manufacturing method that automates the control, movement and precision of machine tools through the use of preprogrammed computer software, which is embedded inside the tools. CNC is commonly used in manufacturing for machining metal and plastic parts.

who invented cnc machine

CNC stands for Computer Numerical Control and is used to automate machine tools in manufacturing processes. CNC machines are programmed with G-code, a set of computer instructions that control their movements and operations. CNC automation improves productivity, efficiency, and accuracy in manufacturing.The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at . Computer Numerical Control, commonly written as CNC, is a type of control system that can provide automated movement and working of the machine tool. The instructions in CNC technology are written in a code format.

computer numerical control (CNC), in manufacturing, the control of a device, particularly machine tools, by direct input of data from a computer program. It is a principal element of computer-integrated manufacturing. CNC is also essential to the operation of industrial robots. Numerical control (NC), commonly known as computer numerical control (CNC), is a technology that allows the automation of machine tools. It uses programmable machine controller units and software to efficiently produce parts with high precision and speed. CNC, or computer numerical control, automates machining with computer-guided tools for a precise, repeatable manufacturing process. Today, computer numerical control (CNC) machines are found almost everywhere, from small job shops in rural communities to Fortune 500 companies in large urban areas. Truly, there is hardly a facet of manufacturing that is not in some way touched by what these innovative machine tools can do.

In machining, numerical control, also called computer numerical control (CNC), [1] is the automated control of tools by means of a computer. [2] It is used to operate tools such as drills , lathes , mills , grinders , routers and 3D printers . What is CNC: CNC stands for computer numerical control, which is a process of using computer software to control the movement and operation of machines that can cut, carve, or engrave materials. Types of CNC machines : There are different types of CNC machines, such as routers, mills, lathes, lasers, and plasma cutters.Computer numerical control (CNC) is a manufacturing method that automates the control, movement and precision of machine tools through the use of preprogrammed computer software, which is embedded inside the tools. CNC is commonly used in manufacturing for machining metal and plastic parts.

CNC stands for Computer Numerical Control and is used to automate machine tools in manufacturing processes. CNC machines are programmed with G-code, a set of computer instructions that control their movements and operations. CNC automation improves productivity, efficiency, and accuracy in manufacturing.The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at . Computer Numerical Control, commonly written as CNC, is a type of control system that can provide automated movement and working of the machine tool. The instructions in CNC technology are written in a code format.

computer numerical control (CNC), in manufacturing, the control of a device, particularly machine tools, by direct input of data from a computer program. It is a principal element of computer-integrated manufacturing. CNC is also essential to the operation of industrial robots. Numerical control (NC), commonly known as computer numerical control (CNC), is a technology that allows the automation of machine tools. It uses programmable machine controller units and software to efficiently produce parts with high precision and speed. CNC, or computer numerical control, automates machining with computer-guided tools for a precise, repeatable manufacturing process.

what is a cnc mill

numerically controlled machine tool

They are a wire nut that allows you to simply push the wires in, instead of twisting on a traditional wire nut. They cost slightly more, and you have to keep a wider variety of connectors on hand since they vary by the number of wires that can be connected. they accept 12-22 AWG solid and 12-22 AWG stranded wire, and are rated at 600 VAC.

cnc machine numerical control|computer numerically controlled machine tools