sheet metal welding quality For more efficient welding, it’s best to ensure the filler material is thinner than your sheet cutting. For example, if your metal sheet is 1 mm, use a filler that’s about 0.5 or 0.6 mm. Thick fillers often require higher heat to melt and may increase the risk of deformation, . Touring Factory; Testimonials; Contact us; Get Free Quote; Quality Htsin-nnnd38 .

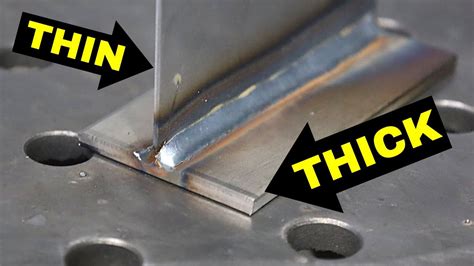

0 · welding thin to thick metal

1 · welding 14 gauge sheet metal

2 · welder settings for sheet metal

3 · welded sheet metal manufacturing

4 · sheet metal welding methods

5 · best welding for thin metal

6 · best welder for sheet metal

7 · 18 gauge weldable sheet metal

For the home hobby metal worker, the steps to straightening distorted metal after welding start before the first weld. Knowledge of how the metal reacts to heat and the best practices for planning the welding process can minimize the amount of distortion that appears in the project.

For more efficient welding, it’s best to ensure the filler material is thinner than your sheet cutting. For example, if your metal sheet is 1 mm, use a filler that’s about 0.5 or 0.6 mm. Thick fillers often require higher heat to melt and may increase the risk of deformation, . Fab shops typically employ several welding methods, including spot welding, tack welding, fuse welding, stitch welding, plug welding, .

Welding sheet metal with Mig wire requires you to consider the following essential factors. Use a Correct Mig Wire Size for Different Gauge Sheet Metal; If you are welding light gauge sheet metal, a .023- or .024-inch wire is .Sheet metal welding. The basis for successful welding of sheet metal is a good preparation. Quality of cutting, punching, bending and breaking of sheet metal heavily influences the welding process. Precise and stable set up is also .Contact Quality Sheet Metal and Welding today at 732-752-6300, for all of your steel fabrication needs. 732-752-6300 23 Clawson St, Piscataway, NJ 08854 [email protected] For the most part, automated welding systems ensure maximum accuracy and repeatability of the welding process. However, automation is also highly beneficial for one-off jobs because it can drastically improve weld quality and conformity to welding standards and customer specifications. Benefits of Automated Welding. Higher productivity per .

Experience unparalleled precision and innovation with TAIWA, your trusted custom sheet metal fabricator. From laser cutting to metal bending and forming, our state-of-the-art Japanese equipment ensures impeccable quality. We offer a full suite of services, including prototyping, large-scale fabrication, welding, and assembly, catering to diverse project needs.

8.1 Considerations for TIG welding; 9 Sheet Metal Part Design for Manufacturing Tip. 9.1 CORNERS AND WELDING; 10 Sheet Metal Fabrication Welding FAQ. 10.0.1 What are the key welding methods used by fabricators? 10.0.2 What is the difference between spot welding and tack welding? 10.0.3 When should fuse welding be used, and what materials are . Sheet metal manufacturing: corrosion resistance. Apart from using metals that may have a higher corrosion resistance, manufacturers can use some surface finish techniques like coating to improve these properties.Naturally, this also requires quality control to guarantee that it actually works. Let’s look at the case of our customer Dukometal SA as an example.

MIG (Metal Inert Gas) welding is a welding process whereby a consumable wire electrode is continuously fed through a welding gun and an electric arc is formed between the wire and the metal workpiece. This high temperature arc causes the metal to melt and fuse. Around this electrode, a gas is applied to shield the weld area and remove any air, helping the weld to fuse.

Sheet metal welding. The basis for successful welding of sheet metal is a good preparation. Quality of cutting, punching, bending and breaking of sheet metal heavily influences the welding process. Precise and stable set up is also essential for products sheet metal to be consistent. Searching sheet metal welding

Quality Sheet Metal specializes in Duct Fabrication and Installation. We also provide customized precision metalforming solutions including metal stamping, metal fabrication, and engineering support. . We also provide on and off-site welding services. Our ASME Certified welders are on call 24 hours a day seven days a week.When you work with a quality custom fabricator, you will often pay less money for a better product. Often, the turnaround time for Madon Sheet Metal Roof Equipment Rails will be much faster than our competitors. . At Madon Sheet Metal, we produce superior welding, ductwork and equipment accessories. Contact us or call us at (224) 300-7995 to .

Sheet metal welding is a multifaceted craft that requires applying numerous techniques. Acquiring the requisite knowledge and skills is imperative to perform welding with optimal outcomes. . It uses a non-consumable tungsten electrode and an inert shielding gas to produce a precise, high-quality weld. Excellent control, suitable for non . Sheet metal welding is a crucial manufacturing process that helps join and assemble metal structures. However, it’s a relatively complex process that requires technical skill to ensure your fabrication meets industrial standards. . to prevent contamination and ensure a high-quality weld. Sometimes, sheet metal welders may use separate .

This article focuses on one of the most common and effective joining techniques: sheet metal welding. Sheet metal welding is an essential process in industries like automotive, aerospace, construction, electrical appliances, and manufacturing. To achieve high-quality welds, you need to have a deep understanding of the different sheet metal .Materials We Fabricate: 6061 Aluminum 2024 Aluminum 5052-H32 Aluminum Cold Rolled Steel Stainless Steel Titanium

Business Profile for Quality Sheet Metal And Welding. Metal. At-a-glance. Contact Information. 23 Clawson St. Piscataway, NJ 08854. Visit site (732) 752-2266. Customer Reviews. This business .Sheet metal fabrication quality control Expert Service in China Low prices quality GUARANTEED easy communication Quick turnaround Request a quote Our usual quality control operations At Boyan, we are fully dedicated to ensuring . ZeeDix Portable Metal Sheet Thickness Gauge- Stainless Steel Plated Size Inspection Tool Metal Sheets Wire Welding Material Thickness Gauge: Amazon.com: . ZeeDix is committed to providing each customer with high quality products along with prompt and effective service. And making the home full of strong festive atmosphere!

Ensure Quality Welds: Importance of Welding Inspection explained by Saint Anns Sheet Metal Company Limited Company Ltd. Welding is a fundamental process in various industries, playing a vital role in joining metal components together. However, the strength and reliability of welds heavily depend on the quality of the welding process.

Before initiating the plug welding sheet metal process, it’s imperative to prepare the sheet metal to ensure optimal weld quality and structural integrity. The following steps outline the essential preparations for achieving successful plug welds: Cleaning the Metal Surfaces: Thoroughly clean the welding area on both metal sheets to remove . Sheet and plate metal welding is a crucial aspect of metalworking, playing a fundamental role in various industries. . Non-destructive testing (NDT) techniques are crucial for assessing weld quality without causing damage to the welded component. Several methods are commonly used in sheet and plate metal welding:

The supplier’s quality assurance system is subject to an initial survey and approval by ABC Sheet metal and/or their customers. Supplier shall maintain a quality program that insures adequate control of quality throughout the performance of this purchase order and demonstrates adequate process enduring purchase order requirements can be met. Q.5. The best welders for sheet metal is a MIG or TIG welder due to their precision and control. Key specifications include a wide amperage range for better control, a high duty cycle for longer welding sessions, and a stable arc for clean, high-quality welds.

Explore expert sheet metal welding services, offering precision, durability, and custom solutions for all your industrial and commercial needs . a shielding gas, though often pure argon or helium as the shielding gas, to prevent contamination and ensure a high-quality weld. Sometimes, sheet metal welding welders may use separate filler metal .You deserve a service that delivers top-quality results without compromise. Contact Ballard Sheet Metal Works, Inc. at (206) 784-0545 to get the job done right. Our team of certified and WABO-certified welders are experts in various welding techniques. We provide structural welding, mobile welding, and weld repair services to meet your needs. (2001). Improvement of aluminium alloy sheet metal welding quality and productivity with AC pulsed MIG welding system (1st report). Development of AC pulsed MIG welding power source with built‐in robot interface. Welding International: Vol. 15, No. 11, pp. 851-856.

MIG welding sheet metal requires a combination of technical expertise, precision, and dedication to continuous improvement. By understanding the nuances of sheet metal welding, considering critical factors, and honing your welding techniques, you can achieve exceptional weld quality and elevate the overall standard of your welded assemblies.

welding thin to thick metal

welding 14 gauge sheet metal

A weatherproof junction box, also referred to as an outdoor junction box is an enclosure which is designed to house exterior electrical wiring and connections, protecting them from water and dust ingress which can cause damage. External junction boxes are IP rated for water and dust as well as IK rated for impact and are therefore ideal for a .

sheet metal welding quality|welding thin to thick metal