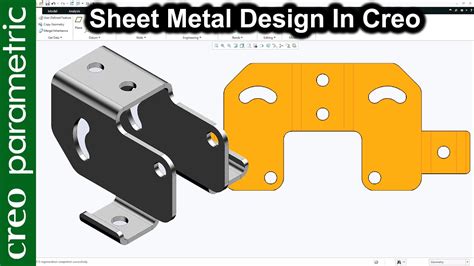

creo sheet metal drawing pdf Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (1) Level: basic, Year 10/11 Contribution to D&T, Maths, Science: design and creation . I need to bulk order electrical boxes for outlets for metal studs for a new installation. Studs are 3 5/8". Electrical is being run with Metal clad cable. MC lite. I'm in nyc so i need metal boxes with side clamps. What size and depth .

0 · sheet metal creo parametric

1 · flat pattern sheet metal drawing

2 · creo sheet metal tutorial PDF

3 · creo sheet metal tutorial

4 · creo sheet metal practice drawing

5 · creo sheet metal basics

6 · creo practice sheet metal models

7 · creo parametric sheet metal tutorial

A roof color visualizer is a free software program that Western States Metal Roofing offers where you can upload a photo of your home and digitally try out different metal panels and colors on your roof (and siding) to get the best idea of how each combination will look.Whether you prefer neutral hues (such as white, black, and gray), natural wood finishes, or bolder shades (such as Kelly green, purple, or yellow), stainless steel appliances provide a neutral base that allows you to take more risk when it comes to the color of your .

Ensure you have the sheetmetal module attached to your license of Pro/ENGINEER before beginning. 1. Create a part (sub-type sheetmetal) with extruded wall as first feature; sketch as .

Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (2) This method of working with sheet metal is to create the model within sheet metal .

Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (1) Level: basic, Year 10/11 Contribution to D&T, Maths, Science: design and creation .Creotm Parametric to create, view, and annotate models and drawings. Detailed Drawings support additional view types and multisheets, offers numerous commands for manipulating .In Creo Parametric, the parametric part modeling process involves the following steps: 1. Set up Units and Basic Datum Geometry. 2. Determine the type of the base feature, the first solid feature, of the design. Note that Extrude, Revolve, .Every sheet metal design starts with the decision for a certain manufacturing shop and a specific material. Then you go on with creating a basic sheet metal part. You must first use a workplane and create the 2D geometry which defines the .

sheet metal creo parametric

This training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features. On completion of this course, you .

This document provides an overview of a training course on sheetmetal design using Creo Parametric. The course objectives are to teach students how to create primary and secondary sheetmetal walls, apply various features, generate flat .SheetmetalusingCreoParametric4.0 Overview CourseCode TRN-5107-T CourseLength 16Hours Inthiscourse,youwilllearnhowtocreate sheetmetalpartsinCreoParametric.The

To create a sheet metal part in Pro/E, choose Sheetmetal instead of selecting Solid from the New (file) dialog. The FEAT CLASS menu structure appears differently in Pro/SHEETMETAL mode. protrusion. After constructing the first Wall feature, you may create surface or solid features, as well as datum or sheet metal features.Ensure you have the sheetmetal module attached to your license of Pro/ENGINEER before beginning. 1. Create a part (sub-type sheetmetal) with extruded wall as first feature; sketch as in following figure: FEATURE / CREATE / WALL / EXTRUDED / DONE / ONE SIDE / DONE / select your planes etc.

flat pattern sheet metal drawing

Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (2) This method of working with sheet metal is to create the model within sheet metal from a number of flat pieces joined together. The alternative is to create a solid first then shell it before opening the sheet metal module. Create and name a new Sheetmetal .

Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (1) Level: basic, Year 10/11 Contribution to D&T, Maths, Science: design and creation of nets for construction of containers, nets of geometrical shapes. This method of working with sheet metal is to create a solid first thenCreotm Parametric to create, view, and annotate models and drawings. Detailed Drawings support additional view types and multisheets, offers numerous commands for manipulating items in a drawing, and lets you add and modify differentIn Creo Parametric, the parametric part modeling process involves the following steps: 1. Set up Units and Basic Datum Geometry. 2. Determine the type of the base feature, the first solid feature, of the design. Note that Extrude, Revolve, or Sweep operations are the most common types of base features. 3.Every sheet metal design starts with the decision for a certain manufacturing shop and a specific material. Then you go on with creating a basic sheet metal part. You must first use a workplane and create the 2D geometry which defines the exact contours of the new basic sheet.

creo sheet metal tutorial PDF

This training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features. On completion of this course, you will have acquired the skills to confidently manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.This document provides an overview of a training course on sheetmetal design using Creo Parametric. The course objectives are to teach students how to create primary and secondary sheetmetal walls, apply various features, generate flat patterns, and create detailed drawings.

SheetmetalusingCreoParametric4.0 Overview CourseCode TRN-5107-T CourseLength 16Hours Inthiscourse,youwilllearnhowtocreate sheetmetalpartsinCreoParametric.TheTo create a sheet metal part in Pro/E, choose Sheetmetal instead of selecting Solid from the New (file) dialog. The FEAT CLASS menu structure appears differently in Pro/SHEETMETAL mode. protrusion. After constructing the first Wall feature, you may create surface or solid features, as well as datum or sheet metal features.

Ensure you have the sheetmetal module attached to your license of Pro/ENGINEER before beginning. 1. Create a part (sub-type sheetmetal) with extruded wall as first feature; sketch as in following figure: FEATURE / CREATE / WALL / EXTRUDED / DONE / ONE SIDE / DONE / select your planes etc.

Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (2) This method of working with sheet metal is to create the model within sheet metal from a number of flat pieces joined together. The alternative is to create a solid first then shell it before opening the sheet metal module. Create and name a new Sheetmetal . Creo Parametric: Creation of a simple part and flat pattern in the Sheet Metal module (1) Level: basic, Year 10/11 Contribution to D&T, Maths, Science: design and creation of nets for construction of containers, nets of geometrical shapes. This method of working with sheet metal is to create a solid first thenCreotm Parametric to create, view, and annotate models and drawings. Detailed Drawings support additional view types and multisheets, offers numerous commands for manipulating items in a drawing, and lets you add and modify differentIn Creo Parametric, the parametric part modeling process involves the following steps: 1. Set up Units and Basic Datum Geometry. 2. Determine the type of the base feature, the first solid feature, of the design. Note that Extrude, Revolve, or Sweep operations are the most common types of base features. 3.

Every sheet metal design starts with the decision for a certain manufacturing shop and a specific material. Then you go on with creating a basic sheet metal part. You must first use a workplane and create the 2D geometry which defines the exact contours of the new basic sheet.This training course enables you to use your introductory modeling skills to create sheet metal models, including walls, bends, notches, and form features. On completion of this course, you will have acquired the skills to confidently manipulate sheet metal geometry, adjust bend developed lengths, and convert solid parts.This document provides an overview of a training course on sheetmetal design using Creo Parametric. The course objectives are to teach students how to create primary and secondary sheetmetal walls, apply various features, generate flat patterns, and create detailed drawings.

creo sheet metal tutorial

creo sheet metal practice drawing

creo sheet metal basics

I am trying to install additional outlets under the eave of my home and I want to use old work boxes with waterproof covers. My under eave soffit is hardie board and I will be using GFCI plugs, but I just want to make sure I'm using the right method under code.

creo sheet metal drawing pdf|sheet metal creo parametric