bending thin sheet metal Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the . Very light gauge steel, flimsy drawer slides, and cheap in general. I also have several Lista cabinets in my home garage. Lista is widely used in race shops, and are top quality.

0 · types of bending sheet metal

1 · sheet metal bending standards

2 · sheet metal bending near me

3 · sheet metal bending guidelines

4 · sheet metal bending chart

5 · problems with sheet metal bending

6 · bending sheet metal by hand

7 · bending galvanized sheet metal

Sheet metal screws come in various lengths, grades, drive types, thread types and materials (such as stainless steel). Uses of sheet metal screws include sealing panels, attaching hinges to cabinets and mounting decorative fixtures.

types of bending sheet metal

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See moreThis guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts.Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are .

If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with.

Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the .

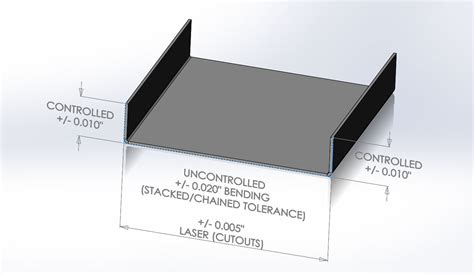

Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make .In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.

If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's how to easily bend thin-gauge sheet metal.

Sheet metal is a thin, malleable piece of metal. Since it’s so thin, you can bend it and it will keep its shape. To bend sheet metal, you simply need to squeeze it between parts . Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

This guide explores sheet metal bending processes, materials suitable for bending, factors to consider and design tips for bending sheet metal parts.Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack. If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's a cool trick for bending thin-gauge sheet metal with. Sheet metal bending is the forming of metal into different geometries, by using a force to deform the metal. It is referred to as sheet metal bending as a thin sheet of metal is bent once, or multiple times, to form the final geometry. The thickness of sheet metal used can vary.

Sheet metal bending can be done using many methods. We discuss those along with springback, bend allowances, k factor, design tips etc.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.

sheet metal bending standards

In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace.If you've got scrap sheet metal around, you can put it to use in projects to save material costs. Here's how to easily bend thin-gauge sheet metal.

Study with Quizlet and memorize flashcards containing terms like Who is born at the start of the film, How does Amelie's mother die, What does Amelie find hidden inside her wall? and more.

bending thin sheet metal|bending sheet metal by hand