bending process in sheet metal ppt Common forming operations include bending, drawing, stamping, spinning, . Explosion proof junction boxes are electrical enclosures designed to protect users from hazardous areas and prevent the propagation of flames or sparks in explosive environments. They do this by isolating specific circuits and .

0 · sheet metal working process pdf

1 · sheet metal calculations pdf

2 · sheet metal bending guide pdf

3 · sheet metal bending chart

4 · sheet metal bend allowance chart

5 · maximum thickness sheet metal bending

6 · bending sheet metal by hand

7 · bend sheet metal without brake

Direct Current Distribution Box is used to protect the solar power generating system if there is any fault during a failure on the DC side. The DC Distribution Box incorporates fuses to switch off the system during the fault, there is a surge protection device to save your system from any surges that occur due to fault or another phenomenon.

BENDING Bending of sheet metal is a common and vital process in manufacturing industry. Sheet metal bending is the plastic deformation of the work over an axis, creating a .Common forming operations include bending, drawing, stamping, spinning, .Sheet metal forming operations include bending, stretching, deep drawing, and .

homebase metal brackets

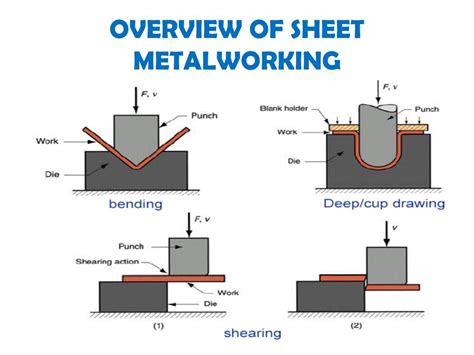

The document discusses various sheet metal processes including shearing, . Common forming operations include bending, drawing, stamping, spinning, and stretching. Cutting operations include blanking, punching, and shearing. 3. Bending involves curving sheet metal between a punch and die. . Sheet metal forming operations include bending, stretching, deep drawing, and other processes where sheets are formed. Bending involves shaping a straight length into a curve and can be done using presses or rolls. . Sheet metal working involves cutting, bending, drawing, and other forming operations to shape metal sheets. The processes include shearing, blanking, and punching, with various tools like punches and dies.

Basic Types of Sheet Metal Processes • Cutting • Shearing to separate large sheets • Blanking to cut part perimeters out of sheet metal • Punching/ Piercing to make holes in .

The cutting and bending processes are important for manufacturing sheet metal parts for a wide range of applications. The document discusses various sheet metal working processes including cutting operations like shearing, blanking, .The document also discusses bending sheet metal, tube bending, stretch forming, deep drawing, rubber forming, spinning, super plastic forming, and explosive forming. It provides examples and diagrams to illustrate key aspects of each . Sheet Metal Forming Process and Their Application. Sheet metal forming process is carried out in the plane of the sheet by tensile forces with a high ratio of surface area to thickness. The high rate of production and .

Sheet metal embossing is a stamping process for producing raised or sunken designs or relief in sheet metal. This process can be made by means of matched male and female roller dies, or by passing sheet or a strip of metal between . The document discusses various sheet metal processes including shearing, bending, drawing, and special forming processes. It provides details on: - Common shearing operations like punching, blanking, and notching used to . BENDING Bending of sheet metal is a common and vital process in manufacturing industry. Sheet metal bending is the plastic deformation of the work over an axis, creating a change in the part's geometry. Similar to other metal forming processes, bending changes the shape of the work piece, while the volume of material will remain the same. Common forming operations include bending, drawing, stamping, spinning, and stretching. Cutting operations include blanking, punching, and shearing. 3. Bending involves curving sheet metal between a punch and die. Drawing uses .

Sheet metal forming operations include bending, stretching, deep drawing, and other processes where sheets are formed. Bending involves shaping a straight length into a curve and can be done using presses or rolls. 2. Deep drawing uses a die and punch to shape flat sheets into cup-shaped parts.

Sheet metal working involves cutting, bending, drawing, and other forming operations to shape metal sheets. The processes include shearing, blanking, and punching, with various tools like punches and dies. Basic Types of Sheet Metal Processes • Cutting • Shearing to separate large sheets • Blanking to cut part perimeters out of sheet metal • Punching/ Piercing to make holes in sheet metal • Bending • Straining sheet around a straight axis • Drawing • Forming of sheet into convex or concave shapes EMUThe cutting and bending processes are important for manufacturing sheet metal parts for a wide range of applications. The document discusses various sheet metal working processes including cutting operations like shearing, blanking, and punching and describes how they work.

The document also discusses bending sheet metal, tube bending, stretch forming, deep drawing, rubber forming, spinning, super plastic forming, and explosive forming. It provides examples and diagrams to illustrate key aspects of each forming technique.

Sheet Metal Forming Process and Their Application. Sheet metal forming process is carried out in the plane of the sheet by tensile forces with a high ratio of surface area to thickness. The high rate of production and formability is determined by its mechanical properties.Sheet metal embossing is a stamping process for producing raised or sunken designs or relief in sheet metal. This process can be made by means of matched male and female roller dies, or by passing sheet or a strip of metal between rolls of the desired pattern.

The document discusses various sheet metal processes including shearing, bending, drawing, and special forming processes. It provides details on: - Common shearing operations like punching, blanking, and notching used to cut sheet metal. BENDING Bending of sheet metal is a common and vital process in manufacturing industry. Sheet metal bending is the plastic deformation of the work over an axis, creating a change in the part's geometry. Similar to other metal forming processes, bending changes the shape of the work piece, while the volume of material will remain the same. Common forming operations include bending, drawing, stamping, spinning, and stretching. Cutting operations include blanking, punching, and shearing. 3. Bending involves curving sheet metal between a punch and die. Drawing uses . Sheet metal forming operations include bending, stretching, deep drawing, and other processes where sheets are formed. Bending involves shaping a straight length into a curve and can be done using presses or rolls. 2. Deep drawing uses a die and punch to shape flat sheets into cup-shaped parts.

Sheet metal working involves cutting, bending, drawing, and other forming operations to shape metal sheets. The processes include shearing, blanking, and punching, with various tools like punches and dies. Basic Types of Sheet Metal Processes • Cutting • Shearing to separate large sheets • Blanking to cut part perimeters out of sheet metal • Punching/ Piercing to make holes in sheet metal • Bending • Straining sheet around a straight axis • Drawing • Forming of sheet into convex or concave shapes EMUThe cutting and bending processes are important for manufacturing sheet metal parts for a wide range of applications. The document discusses various sheet metal working processes including cutting operations like shearing, blanking, and punching and describes how they work.The document also discusses bending sheet metal, tube bending, stretch forming, deep drawing, rubber forming, spinning, super plastic forming, and explosive forming. It provides examples and diagrams to illustrate key aspects of each forming technique.

home it steel bread box

Sheet Metal Forming Process and Their Application. Sheet metal forming process is carried out in the plane of the sheet by tensile forces with a high ratio of surface area to thickness. The high rate of production and formability is determined by its mechanical properties.Sheet metal embossing is a stamping process for producing raised or sunken designs or relief in sheet metal. This process can be made by means of matched male and female roller dies, or by passing sheet or a strip of metal between rolls of the desired pattern.

sheet metal working process pdf

home depot two gang metal box

sheet metal calculations pdf

sheet metal bending guide pdf

There are two basic ways to lay out a flat blank, and which to use will depend on the information that you are given to work with. For the first method, you need to know the leg dimensions. A leg is any flat area of a part, .

bending process in sheet metal ppt|maximum thickness sheet metal bending