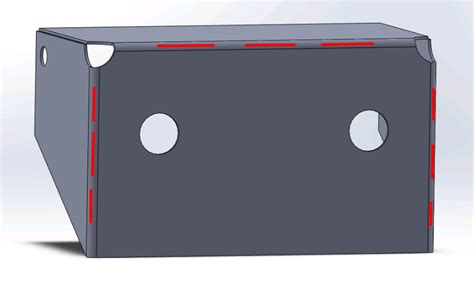

bend relief for sheet metal Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part. Figure "B" shows a part with the edge a sufficient distance . Usually if it is smaller pipe and I bend the Box Offset my first bend is a fingers width away from the end of the pipe (so I know where my first bend started and it doesn't pinch the end of the pipe), second bend is as close as I can get to .

0 · solidworks sheet metal relief cut

1 · solidworks sheet metal corner relief

2 · solidworks sheet metal bend relief

3 · sheet metal fabrication design guide

4 · sheet metal corner relief chart

5 · sheet metal bending chart

6 · sheet metal bend relief guidelines

7 · auto relief solidworks sheet metal

Whether you plan to sell custom wooden wares on Etsy, or need a more professional CNC router for prototyping or commercial part production, there’s a tool to match your project and budget.

A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. They are a .

Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part. Figure "B" shows a part with the edge a sufficient distance .

Bend Relief in Sheet Metal Bend Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Recommended Bend Relief height is . Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Although they are small features, leaving . In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced techniques and real-world applications that contribute to successful fabrication endeavors.

The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether you are coining or air bending on a press brake, and adding bend . Bend reliefs prevent tears during transitions between bends or between a bend and a flat surface. They ensure a clean part free from deformation, burrs, and sharp points, especially crucial for parts subject to .Missing or Insufficient Bend Relief. Bend relief allows two bend regions to connect on the ends, without "fighting over" which bend gets to deform the metal. In the flat pattern below, two different bends at 90 degrees meet on the end of the . See how and when specifically to design bend reliefs and corner reliefs in sheet metal parts to open up geometry options & tighter tolerances

solidworks sheet metal relief cut

A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. They are a great way to ensure a clean looking part that is free from deformation, burrs, and sharp points where the bend edges terminate.Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part. Figure "B" shows a part with the edge a sufficient distance from the form. This distance should never be less than the radius of the bend.Bend Relief in Sheet Metal Bend Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Recommended Bend Relief height is always more than two times of sheet thickness plus bend radius.

solidworks sheet metal corner relief

Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Although they are small features, leaving them out can cause stress to concentrate at the bend line, resulting in deformed holes and slots. In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced techniques and real-world applications that contribute to successful fabrication endeavors.

The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether you are coining or air bending on a press brake, and adding bend relief to prevent tearing material. Bend reliefs prevent tears during transitions between bends or between a bend and a flat surface. They ensure a clean part free from deformation, burrs, and sharp points, especially crucial for parts subject to vibration or flexion.

Missing or Insufficient Bend Relief. Bend relief allows two bend regions to connect on the ends, without "fighting over" which bend gets to deform the metal. In the flat pattern below, two different bends at 90 degrees meet on the end of the part, without bend relief:Bend relief, also known as bend allowance or bend deduction, is a design technique used to mitigate the effects of stress and deformation that occur during the bending process. When a metal sheet is bent, the inner radius compresses while the outer radius stretches. See how and when specifically to design bend reliefs and corner reliefs in sheet metal parts to open up geometry options & tighter tolerances

A bend relief prevents tears from occurring where there is a transition between bends or between a bend and a flat surface. They are a great way to ensure a clean looking part that is free from deformation, burrs, and sharp points where the bend edges terminate.Bend Relief - When a bend is made close to an edge the material may tear unless bend relief is given. Figure "A" shows a torn part. Figure "B" shows a part with the edge a sufficient distance from the form. This distance should never be less than the radius of the bend.Bend Relief in Sheet Metal Bend Bend relief is provided at the end of the bending edge in sheet metal design to avoid any crack tearing in the corner. Recommended Bend Relief height is always more than two times of sheet thickness plus bend radius.

Bend reliefs are two small cuts made in a piece of sheet metal to free up the metal between them. Although they are small features, leaving them out can cause stress to concentrate at the bend line, resulting in deformed holes and slots. In this comprehensive guide, we’ll explore the intricate world of sheet metal bend relief guidelines, uncovering advanced techniques and real-world applications that contribute to successful fabrication endeavors. The article discusses making small holes and when to use a punch or laser cutter, inside radius measurements and how they differ depending on whether you are coining or air bending on a press brake, and adding bend relief to prevent tearing material.

signoraware executive steel medium lunch box

Bend reliefs prevent tears during transitions between bends or between a bend and a flat surface. They ensure a clean part free from deformation, burrs, and sharp points, especially crucial for parts subject to vibration or flexion.

Missing or Insufficient Bend Relief. Bend relief allows two bend regions to connect on the ends, without "fighting over" which bend gets to deform the metal. In the flat pattern below, two different bends at 90 degrees meet on the end of the part, without bend relief:

solidworks sheet metal bend relief

It’s something Apple has include with most iPhone models since the 3G, and it has a single purpose. To eject the SIM card tray. And why would you need to do that? Well that's what I'll explain in.

bend relief for sheet metal|solidworks sheet metal corner relief