sheet-bulk metal forming process By applying bulk forming processes to sheet metal material the TCRC 73 is providing a significant contribution to the development of forming technologies and thus to the solution of several of . Metal electrical boxes must be connected to the ground system with a grounding pigtail, which links circuit ground wires to the outlet via a green grounding screw. Plastic electrical boxes do not need grounding.

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal operations with diagrams

4 · sheet metal forming process pdf

5 · sheet metal bending process pdf

6 · forming sheet metal by hand

7 · bulk deformation vs sheet metal forming

My concern is the wiring the new transformer properly. The new transformer new transformer has the Hot (black), Neutral (White), Ground (Green) wiring. When I disconnect the disconnect the old transformer from the sides of the outlet, how can I tell where to connect the Black and White wires?

In sheet-bulk metal forming processes, the bulk deformation of sheet is carried out that invariably brings out the intended changes in the thickness as well. Some examples of bulk metal . SBMF unites the advantages of sheet and bulk metal forming processes. Cold forging has among others the advantages of strain hardening during the forming process, high . Sheet-bulk metal forming processes are forming processes in which often conventional sheet and bulk forming operations are combined. These processes are applied to .By applying bulk forming processes to sheet metal material the TCRC 73 is providing a significant contribution to the development of forming technologies and thus to the solution of several of .

Sheet-bulk metal forming – forming of functional components from sheet metals. August 2015. MATEC of Conferences 21 (2):01001. DOI: 10.1051/matecconf/20152101001..

This paper is focused on a combined deep drawing and extrusion process dedicated to the new process class of sheet bulk metal forming (SBMF).

กลุ่มกระบวนการขึ้นรูปโลหะแผ่น (Sheet Metal Forming Process) และถ้าวัสดุเริ่มต้นมีลักษณะเป็นก้อน (Bulk Metal Forming Process) จะเป็นกระบวนการขึ้นรูปโลหะก้อน The design, manufacturing and further processing of Tailored Blanks in a sheet-bulk metal forming process is analysed and presented using numerical models and verified by experimental tests. The process combination of deep drawing and upsetting enables the single-stage manufacturing of cups with an external gearing. Specific challenges .

[Show full abstract] discussed include new flexible bulk and sheet metal forming technologies for large components, online process and product property control, lightweight design opportunities . Due to rising demands regarding the functionality and load-bearing capacity of functional components such as synchronizer rings in gear systems, conventional forming operations are reaching their limits with respect to formability and efficiency. One way to meet these challenges is the application of the innovative process class of sheet-bulk metal forming . Due to ecological and economic challenges there is a rising demand on closely-tolerated complex functional components. Regarding short process chains and improved mechanical properties conventional forming processes are often limited. A promising approach to meet these requirements can be seen in the combination of traditional sheet and bulk metal .

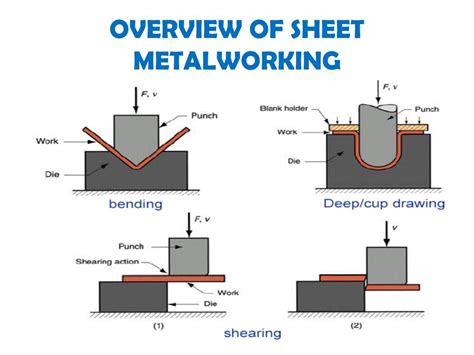

By comparing the process chain of PBF-LB and forming (Fig. 2) with the process chain of subsequent sheet bulk metal forming operations (Fig. 5) it can be seen that, the main difference is the process step for manufacturing the tooth geometry on the sheet metal. In case of the hybrid approach, the tooth geometries are manufactured by PBF-LB on a . Forming Process has been classified into two groups; Bulk-forming and Sheet metal forming. Further, the detailed classification of the forming process as you can see in the layout above. . The punch and die are used as tools in the fabrication process. Sheet metal forming is associated with operations; Bending, Drawing, Shearing, Blanking . 2. BULK DEFORMATION PROCESSES: Metal forming operations which cause significant shape change by deformation in metal parts whose initial form is bulk rather than sheet. These processes work by stressing metal sufficiently to cause plastic flow into desired shape. Performed as cold, warm, and hot working operations. In hot working, significant shape .Maximizes reader understanding/skills with technologic and business projects with solutions and process flow diagrams; Reinforces concepts presented with applications, 200 worked numerical examples, 125 diagrams and 100 MCQs with answers . sheet-metal forming, and sheet-bulk-metal forming. Theory of metal forming is presented by discussing .

Bulk Upload for Production Quotes. Onboard Xometry As Your Vendor. . This sheet metal forming process is often used for vehicle body parts, enclosures, and electrical components. It can be performed on most compatible sheet metal forming materials, like stainless steel, brass, aluminum, and galvanized steel. . This paper is focused on a combined deep drawing and extrusion process dedicated to the new process class of sheet bulk metal forming (SBMF). Exemplified by the forming of gearings, combined sheet and bulk forming operations are applied to sheet metal in order to form local functional features through an intended and controlled change of the sheet .

Effects of process parameters on the deformation energy in a sheet-bulk metal forming process for an automotive component. Author links open overlay panel Mohamad El Mehtedi a, Pasquale Buonadonna a, Antonello D’Annibale b, . considering the parameter effects in sheet-bulk metal forming [15] and the material workability model [16,17 .

2. Wire or rod drawing: similar to extrusion, except that the workpiece is pulled through the die opening to take the cross-section. Classification of basic bulk forming processes Rolling Forging Extrusion Wire drawing Rolling: In this process, the workpiece in the form of slab or plate is compressed between two rotating rolls in the thickness direction, so that the .

The sheet-bulk metal forming (SBMF) process class can meet these requirements by applying bulk forming to semi-finished sheet metal products. This is often done in combination with sheet metal forming processes, which expand the range of components that can be produced [1]. The combination of bulk and sheet metal forming leads to challenges . This innovative process class, also called sheet-bulk metal forming (SBMF), facilitates the forming of minute functional elements such as lock toothing and gear toothing on sheet-metal bodies.

glitzhome metal and wooden christmas house decor

Deep drawing is a sheet metal forming process used to fabricate cup-shaped parts; bar drawing is a bulk deformation process used to reduce the diameter of a cylindrical work part. What are some of the advantages of cold working relative to warm and hot working? Power metal forming process; Bulk Forming Processes. Bulk forming process involves using raw materials with a low surface area to volume ratio for shaping. This category includes processes like rolling, forging, .

The present contribution deals with the process-machine interaction and its impacts on the workpiece quality by forming parts with sheet-bulk metal forming. It focuses on the manufacturing of complex asymmetrical parts with functional elements. The functional applications of these elements such as fixation, motion and load transmission require compliance with high . Flo w forming is according to [6] an incremental sheet-bulk metal forming process with a rotational. tool movement to reduce the sheet thickness at low forming forces. It is characterized by a local. PENJELASAN DIAGRAM MEETAL FORMING. bulk deformation process; . Sheet metal forming proses merupakan proses pembentukan logam pada logam lembaran (sheet), logam strip dan coil biasannya dilakukan dengan cold working yang karakteristiknya perbangingan luas permukaan denagn volume yang tinggi. Sheet metal forming prosess . Sheet bulk metal forming is a composite plastic processing technology based on sheet metal forming and bulk forming, which can form non-uniformly thick and complex sheet metal parts with 3D characteristics nearly net [].This method can effectively promote the process of lightweight forming and reduce production costs [2, 3].Sheet bulk metal forming process has .

conditions for a specific sheet-bulk metal forming process were defined by numerical investigations. The results reveal that a local increase of the friction leads to an improved die filling of the functional elements. Based on these results abrasive blasting as a method to modify the tool surface and thus influencing the A new sheet-bulk metal forming process for the production of bulk components out of a flat sheet has been developed. Superimposed oscillation has been applied to the new process. By this means .Explanation: Bulk forming is a deformation process which results in a massive shape change of the material. The ratio of surface area to volume of the material is relatively small. It includes processes like forging, extrusion and rolling. But the bending process is a part of sheet metal forming which has surface area to volume ratio relatively .

For sheet metal forming process, the most used test in the literature today is the Strip Drawing Test or Bending Under Tension . Tillmann W, Stangier D, Lopes-Dias NF, et al. Adjustment of friction by duplex-treated, bionic structures for Sheet-Bulk Metal Forming. Tribology International. 2017; 111:9-17; 20.

sheet metal working process pdf

In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking Operations The development and advantages of both systems for the sheet bulk metal forming process are shown. Discover the world's research. 25+ million members; 160+ million publication pages;

gluing for galvanized metal to fabric

gluing fabric to metal

glass lunch box with steel lid

glue for sheet metal

The Legrand Wiremold 700 series raceway is ideal for surface mounting small amounts of electrical wiring or communication cables. Surface metal raceway allows you to add fixtures and outlets without disturbing the drywall, plaster or insulation in your home.

sheet-bulk metal forming process|sheet metal bending process pdf