sheet metal process gif I'm sure the forming process causes some heat, but the circular hollow section is put in cold, and roll formed into shape. The process is called cold forming. Causes the steel to increase is . A junction box provides a safe, code-compliant space for housing cable connections for outlets, switches, or splices. They prevent potential electrical shocks, and keep sparks from spreading to flammable surroundings.Choose the right electrical box for your wall sconce based on the fixture’s weight, wall material, and specific installation requirements to ensure a safe and compliant installation.

0 · types of sheet metal operations pdf

1 · types of sheet metal drawings

2 · types of sheet metal diagrams

3 · sheet metal operations diagram

4 · sheet metal operations

5 · sheet metal drawing operations

6 · sheet metal blanking operations

Old work electrical boxes are used when you need to add an electrical box to walls that are closed in or covered with drywall. These boxes are designed to clamp.

GIPHY is the platform that animates your world. Find the GIFs, Clips, and Stickers that make your conversations more positive, more expressive, and more you.

GIPHY is the platform that animates your world. Find the GIFs, Clips, and Stickers .

I’ve just started getting into sheet metal design with Fusion 360. Since I’m riding the parts through a service, I don’t interact with the press setup, but they give rules for bend .

I'm sure the forming process causes some heat, but the circular hollow section is put in cold, and roll formed into shape. The process is called cold forming. Causes the steel to increase is .Browse MakeaGif's great section of animated GIFs, or make your very own. Upload, customize and create the best GIFs with our free GIF animator! See it. GIF it. Share it.This sub is for .gif/.gifv/silent .mp4 images that contain a subject matter of mechanical origin.Find the GIFs, Clips, and Stickers that make your conversations more positive, more expressive, and more you.

GIPHY is the platform that animates your world. Find the GIFs, Clips, and Stickers that make your conversations more positive, more expressive, and more you. The perfect Sheet Metal Animated GIF for your conversation. Discover and Share the best GIFs on Tenor.

Browse MakeaGif's great section of animated GIFs, or make your very own. Upload, customize and create the best GIFs with our free GIF animator! See it. GIF it. Share it. The process, known as sheet metal laser cutting, can develop complex geometries rapidly and accurately in metals like steel, aluminum, and titanium. Hydroforming. Hydroforming uses highly pressurized fluid instead of . Forming is the most widely used sheet metal operation used for manufacturing various sheet metal components across the industry.. Sheet Metal Forming . Image courtesy: Wiki Based upon the manufactured components .

The deburring process in sheet metal processing is vital to ensure safety and the overall finish of the final product. This step involves removing any sharp edges or “burrs” left from the previous processes such as cutting or punching. Edge .Tool, machine, and manufacturing gifs. Sometimes entertaining, always educational. . so it will pick up a hand going through the laser guard but sheet metal with 1/2/3/4/5mm thickness does not activate it when it goes through. . It’s always really cool to see the technicians that design the process work backwards to deconstruct a part and . 06 sheet metal forming - Download as a PDF or view online for free . Suranaree University of Technology Jan-Mar 2007 • Sheet metal forming is a process that materials undergo permanent deformation by cold forming to produce a variety of complex three dimensional shapes. • The process is carried out in the plane of sheet by tensile forces .Sheet metal manufacturing is the process of creating sheet metal parts by cutting, bending, and forming thin metal sheets into specific shapes and sizes. The process typically uses coating, cutting, bending, and assembly techniques. Sheet metal is made from various materials, including steel, aluminum, zinc, and copper.

used steel filing cabinets

Browse MakeaGif's great section of animated GIFs, or make your very own. Upload, customize and create the best GIFs with our free GIF animator! See it. GIF it. Share it. . Sheet Metal Stamping Dies & Processes. 455. Added 4 years ago anonymously in science GIFs Source: Watch the full video | Create GIF from this video. 0.Browse MakeaGif's great section of animated GIFs, or make your very own. Upload, customize and create the best GIFs with our free GIF animator! See it. GIF it. Share it. . Sheet Metal Stamping Dies & Processes. 1642. Added 4 years ago anonymously in misc GIFs Source: Watch the full video | Create GIF from this video. 0.

Figure 1 Schematic diagram of automatic stamping production line. Main production process parameters of the press. Currently, the most widely used presses are mechanical closed presses, which can be used for various cold stamping processes such as blanking, forming, bending, correction, and shallow drawing of thin plate parts.

Sheet Hydroforming Process| PPT | ENGINEERING STUDY MATERIALSSheet hydroforming is a metal forming process that uses pressurized hydraulic fluid in a flexibl.

used woodworking cnc machines for sale

Clinching phases. In metalworking, clinching or press-joining is a bulk sheet metal forming process aimed at joining thin metal sheets without additional components, using special tools to plastically form an interlock between two or more sheets. The process is generally performed at room temperature, but in some special cases the sheets can be pre-heated to improve the . The TOX®-Clinching can be used for versatile customer applications. Be it in the automotive industry or in the production of household appliances such as was.Curling sheet metal is the process of adding a hollow, circular roll to the edge of the sheet. The curled edge provides strength to the edge and makes it safe for handling. Curling is different than a tear drop hem because in a curl the edge finishes inside itself, where a .Join Date May 2024 Posts 1,520 Thanks 0 Thanked 2,590 Times in 1,079 Posts

Sheet Metal FormabilityBasic Stamping Die OperationsGIPHY is the platform that animates your world. Find the GIFs, Clips, and Stickers that make your conversations more positive, more expressive, and more you.Supporting Member Join Date May 2024 Posts 1,358 Thanks 0 Thanked 2,388 Times in 987 PostsInsert Bends or “Convert to Sheet Metal” features. When designing with sheet metal, it is important to think about the best approach to model or design a part. At times, it may appear quicker to use non-sheet metal features (boss-extrude, etc.), and then insert bends or convert to sheet metal. However, these options are problematic

types of sheet metal operations pdf

The difference between these two processes is that coining uses up to 30 times more pressure to bend sheet metal than air bending, making it highly useful for bending thick and/or hard sheet metal. Bottoming. Bottoming is a bending process in which sheet metal is pressed against a bottom die featuring a V shape.Extrusion is a process in which a section of the deep drawn metal is pushed out to create a protrusion. This can be useful for creating certain functional features in a deep drawn box, or other types of deep draw stamping products.. 8. Hole Creation. Holes of various sizes and shapes can be created in deep drawn stampings as per the design requirements. . This step is critical in .

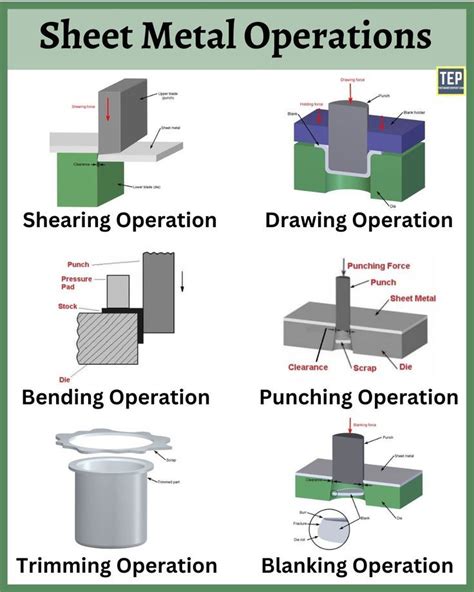

Supporting Member Join Date May 2024 Posts 1,144 Thanks 0 Thanked 2,048 Times in 836 Posts Types of Sheet Metal Operations. Below are the types of sheet metal operations: Shearing Operations. The Shearing operation is cut in a straight line across a strip, sheet, or bar. It leaves a lean edge on the piece of metal that is sheared or cut. In this operation, a sheet metal workpiece is placed or kept between two dies from one end. The process of plastic deformation by deep-drawing sheet metal is used on a large scale in the industry. The main users are the automotive and aeronautical sectors. 5. Sheet Metal Processing The raw material for sheet metal manufacturing processes is the output of the rolling process. Typically, sheets of metal are sold as flat, rectangular sheets of standard size. If the sheets are thin and very long, they may be in the form of rolls. Therefore the first step in any sheet metal process is to cut the correct shape and .

In this blog post, we will delve into the fascinating world of CNC machining using captivating animated GIFs to showcase the process and highlight its key advantages. From detailed machining processes to the latest advancements in CNC technology, join us on a visual journey as we explore the art and science behind CNC machining. . Sheet metal . Hemming is a sheet metal forming process in which sheets are joined by bending it usually to 180°. Automotive body panels and automotive parts such as deck-lids, trunk-lids, doors, hoods and tailgates are formed by hemming process. This paper present a systematic review of sheet metal hemming process based on materials used in hemming process . Sheet Metal GIF SD GIF HD GIF . CAPTION. V. Vishya. Share to iMessage. Share to Facebook. Share to Twitter. Share to Reddit. Share to Pinterest. Share to Tumblr. Copy link to clipboard. Copy embed to clipboard. Report. Sheet Metal. Share URL. Embed. Details File Size: 95KB Dimensions: 498x427 Created: 10/10/2022, 6:00:22 PM.

types of sheet metal drawings

usig outlet box as junction box

Generally, Snap-on toolboxes are constructed using high-quality steel ranging from 16 to 20 gauge thickness. Thicker gauges, such as 16 gauge, offer more durability and .

sheet metal process gif|sheet metal operations diagram