sheet metal process costing Sheet metal fabrication is the art of transforming raw metal sheets into various components and structures, serving a multitude of industries. While you may already be well-acquainted with the basics, we will delve deeper into . $59.99

0 · sheet metal production cost calculator

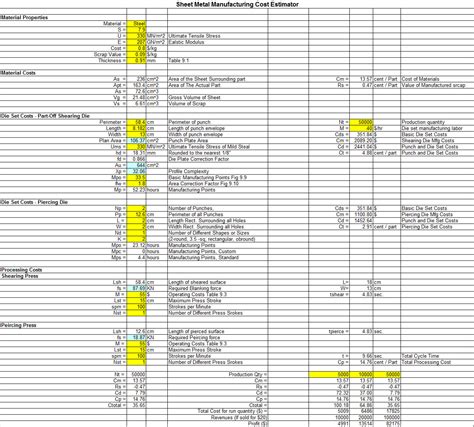

1 · sheet metal production cost

2 · sheet metal manufacturing cost formula

3 · sheet metal manufacturing cost estimator

4 · sheet metal fabrication cost

5 · sheet metal design cost calculator

6 · sheet metal cutting cost

7 · sheet metal cost calculator

Here are 12 examples to get the wheels turning. Perfect for pole beans and morning glories, a tall, spindly tipi trellis adds whimsy along with variation to other structures in the yard. Tip: An added bonus is that these are .

Various factors influence sheet metal fabrication costs, each crucial in determining the final expenses for sheet metal parts. Manufacturers can gain insights into budget allocation and cost control by comprehending these cost . SOLIDWORKS Costing (available in SOLIDWORKS Professional & Premium) is a powerful tool that can estimate production costs for manufactured components using parameters such as raw material costs, . Sheet metal fabrication is the art of transforming raw metal sheets into various components and structures, serving a multitude of industries. While you may already be well-acquainted with the basics, we will delve deeper into . In this blog post, we’ll address six frequently asked questions about cost estimating for sheet metal parts, and introduce you to a solution that can help streamline your estimating process and make your life easier as an .

How to calculate sheet metal part cost.#Costing sheet format#Estimation#manufacturingcost A sheet metal costing sheet is a document that is used to calculate.

Cost accounting is defined by the Institute of Management Accountants as "a systematic set of procedures for recording and reporting measurements of the cost.

This comprehensive course of 15+ hours covers the fundamentals and advanced topics of Sheet Metal engineering & it focus more on costing of sheet metal component and assemblies.. This course is ideal for mechanical, aerospace, automotive, and manufacturing engineers, design engineers, fabrication specialists, and quality control professionals seeking to enhance their . Here, I will use some of the concepts and ideas of these articles and propose a method to estimate the production cost of a single sheet metal product, and of a full batch.

One of the key advantages of sheet metal hydroforming is its ability to produce parts with reduced material waste and cost savings compared to traditional forming methods. The process allows for the use of thinner materials while still maintaining the required strength, which can result in lighter parts and lower production costs.To be competitive in sheet metal fabrication, manufacturers must be able to maximise raw material sheet utilisation. Hexagon’s dedicated sheet metal solutions digitalise the workflow from process planning, simulation and costing to fabrication and inspection, enabling better utilisation and greater efficiency throughout the process. In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking Operations

Sheet metal manufacturing is a vital process in numerous industries, ranging from automotive and aerospace to electronics and construction. Efficiently fabricating sheet metal parts requires a deep understanding of various formulas and their practical applications. In this comprehensive guide, we will delve into the common formulas used in .Http://www.ETMmfg.com 56 UNDERSTANDING SHEET METAL COSTS Our Take on Profits The latest data published by Financial Research Associates for sheet metal fabricators with sales over million indicates that profits are very slim: Net sales Cost of sales Gross Profit Overhead Operating Profit Interest Depreciation Profit Before Tax ,000,000 . How to find the costing of sheet metal componentsजरूर देखना लिंक पे क्लिक करके 👇👇https://youtu.be/0RtVU .Once created, using the embedded model editor, these models have inputs or drop down lists, as well as formulas that quickly and easily complete calculations for manufacturing time and/or cost. Costimator contains hundreds of fabrication process cost models that make estimating sheet metal parts and assembly a breeze.

To prepare costing sheet and quotation. Cost analysis for competitive pricing. . Review and recommend effective process improvement plan to cut down redundancy and eliminate unproductive process; Metal sheet / stamping: 2 years (Preferred). Employer Active 23 .Related Resources: Manufacturing Sheet Metal Manufacturing Cost Estimation Spreadsheet. NOTE: Refunds are not awarded after excel files have been downloaded - review your membership agreement for details.; This excel spreadsheet may contain macros which will need to be enabled in your excel application, see web page: Enable macros in Downloaded excel files

Machine or process setup operations (such as brake setup costs) The Costing tool automatically recognizes a sheet metal part as a part that contains sheet metal features such as flanges, bends, or forming tools. Features such as holes and cuts are recognized as manufacturing cut paths for operations such as laser, water jet, and plasma cutting.

Cost estimating sheet metal manufacturing and fabricated parts and products generally consists of a few basic manufacturing processes namely, cutting a blank to size.

We will discuss a sheet metal fabrication cost calculator using simple ideas and concepts. Step 1: Break Down the Production Cycle. Product development involves various cycles, and production cycles often vary from .Sheet Metal Templates. Custom Operations for Sheet Metal Parts. You can create custom operations to apply additional costs to sheet metal parts. Typically, these are costs for features that are not modeled in the part, such as heat treatment, painting, or shipping. Editing Sheet Metal Operations. You can edit manufacturing operations in the .

electrical box for kitchen cabinet

CustomPartNet is a free resource for engineers and manufacturers that facilitates product design and cost estimation. Learn about the process cycle and design for manufacturing (DFM) guidelines for a wide range of manufacturing processes, including injection molding, metal casting, machining (milling and turning), and rapid prototyping. Get fast and accurate cost estimates by . The SOLIDWORKS Costing tool helps you calculate how much it costs to manufacture sheet metal, machined, multi-body parts, and assemblies, as well as plastic molded cast, 3D printed parts, and.

The calculation of each cost element is dependent on the manufacturing process and will not be explicitly presented here. A depth information about the calculation procedure of the sheet metal .Sheet Metal Forming Process Chain . software speeds up the cost estimation process with the automatic detection of part geometry features and an embedded costing engine for stamping operations. As a result, up to a hundred cost estimations can be made a day, enabling you to meet deadlines for budgets, resource plans and quotations. .DFM Concurrent Costing . Now we are going to change the sheet metal process type and do a cost comparison of the two processes. A compound die analysis 1. Make a copy of the turret press analysis (Click the tab. Edit->Copy, Edit->Paste) 2. A copy is created at the second tab of the Process Chart.or revise labor costs, materials, or manufacturing processes. The following costing operations can be included and analyzed. Making Cents of It: Your Introduction to SOLIDWORKS Costing www.solidprofessor.com 1 Everything You Can Analyze in the SOLIDWORKS Costing Tool Sheet Metal Parts Sheet metal cutting operations Punches and forming tools

Guide to powder coating that explains the process, types of powder coat, how it is done and what are advantages and disadvantages of this coating technique. . 2021 by Staff. Powder coating revolutionized architecture, furniture manufacturing, and outdoor metal maintenance. This versatile coating protects metals and other materials from .We automate the process of calculating the planned production cost of production using Excel formulas. Our task is to create a table using Excel tools so that when you substitute data, the production cost of goods, works, and services is automatically considered. . «Price». All other columns refer to the data of the «Standards» sheet. In .Company A purchased plastic costing ,000 and sheet metal costing ,000 with cash. Both of these materials are used in the production process. Make the necessary journal entry or entries to record these transactions.

But u need to take into consideration that the component is made after going through most of the process so that process cost can be calculated seperately. i need to have an excel sheet as how to do the sheet metal costing. u can even take an example for a round bar or a standard sheet. Register to Reply: ddk. Guru. Join Date: Jul 2007.

sheet metal production cost calculator

electrical box for finished wall

electrical box for concrete pour

electrical box for between studs

electrical box for dryer receptacle

This used to be a “panelboard” enclosure and has been modified into a “junction box,” which (technically) goes against its “listing and labeling.” Every time I have seen this .

sheet metal process costing|sheet metal fabrication cost