beading in sheet metal $123.99 Universal Junction Box UJB94-W KEY FEATURES: Compatible with Select ENS Security Cameras; Compatible Bracket Diameter Range: 2.4-3.7in (60-95mm) Easy Installation; Outdoor or Indoor junction box options; Made of Aluminum; .

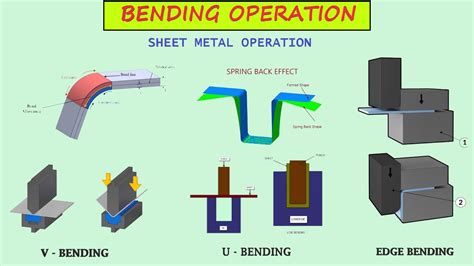

0 · types of sheet metal bending

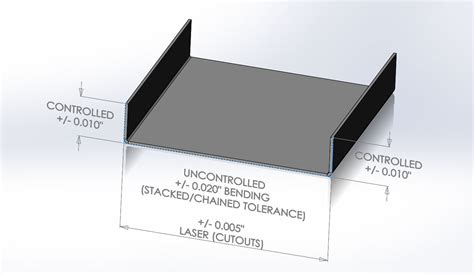

1 · sheet metal bending standards

2 · sheet metal bending dies

3 · maximum thickness sheet metal bending

4 · how to use bead roller

5 · bending sheet metal 90 degrees

6 · beading process in sheet metal

7 · beading machine for sheet metal

Miami Metalwork provides custom metalwork, metal fabrication, ironworks, welding and associated services throughout South Florida and Illinois. All of our work is completed in house at our Miami or Chicago based workshops by our skillful welders and fabricators.

Beading is common in the edge treatment of sheet metal parts and can also be used to form the working structure of parts, such as hinges. Beading forms a curl over a part's edge. This bead can be formed over a straight or curved axis. When stiffening ductwork or other sheet metal products, there are two primary techniques fabricators can employ, cross-braking or beading. Bead rolling adds strength and design features to sheet metal by creating raised or indented lines, known as beads, along the surface. This technique is often employed for .3.99

9.979.976.988.99

Cross breaking and duct beading do essentially the same thing. Both methods are used to add rigidity to the ductwork. The “cold air return” ductwork in your home or office is under ‘negative’ pressure—meaning that .Mark Simpson demonstrates how to use a bead roller to roll flanges and beads when fabricating sheet metals.Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a . Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis.

types of sheet metal bending

Here are some ways to increase the structural strength of flat sheet stock without adding gussets or increasing the weight of the product. If a panel must be extremely rigid and .

Beading machines are mainly used in sheet metal and air ductwork. They are easy to operate and feature rollers for different tasks such as beading, folding and flanging. The standard equipment of every KNUTH beading machine includes .Beading is common in the edge treatment of sheet metal parts and can also be used to form the working structure of parts, such as hinges. Beading forms a curl over a part's edge. This bead can be formed over a straight or curved axis.

When stiffening ductwork or other sheet metal products, there are two primary techniques fabricators can employ, cross-braking or beading. Bead rolling adds strength and design features to sheet metal by creating raised or indented lines, known as beads, along the surface. This technique is often employed for stiffening panels or adding decorative elements to automotive parts. Cross breaking and duct beading do essentially the same thing. Both methods are used to add rigidity to the ductwork. The “cold air return” ductwork in your home or office is under ‘negative’ pressure—meaning that the ductwork wants to pull or suck in. Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.

sheet metal bending standards

Mark Simpson demonstrates how to use a bead roller to roll flanges and beads when fabricating sheet metals.

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die). Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis.

electrical box pulled out of outside wall wall

Here are some ways to increase the structural strength of flat sheet stock without adding gussets or increasing the weight of the product. If a panel must be extremely rigid and non-flexible, beading is a better option for bracing.Beading machines are mainly used in sheet metal and air ductwork. They are easy to operate and feature rollers for different tasks such as beading, folding and flanging. The standard equipment of every KNUTH beading machine includes a stop and a set of four standard rollers.

Beading is common in the edge treatment of sheet metal parts and can also be used to form the working structure of parts, such as hinges. Beading forms a curl over a part's edge. This bead can be formed over a straight or curved axis. When stiffening ductwork or other sheet metal products, there are two primary techniques fabricators can employ, cross-braking or beading. Bead rolling adds strength and design features to sheet metal by creating raised or indented lines, known as beads, along the surface. This technique is often employed for stiffening panels or adding decorative elements to automotive parts.

Cross breaking and duct beading do essentially the same thing. Both methods are used to add rigidity to the ductwork. The “cold air return” ductwork in your home or office is under ‘negative’ pressure—meaning that the ductwork wants to pull or suck in. Bending is one of the most common sheet metal fabrication operations. Also known as press braking , flanging, die bending, folding and edging , this method is used to deform a material to an angular shape.Mark Simpson demonstrates how to use a bead roller to roll flanges and beads when fabricating sheet metals.

sheet metal bending dies

Bending is a fundamental process in sheet metal working that involves deforming a metal workpiece into a desired shape by applying force between two tools by a press brake: an upper tool (known as a punch) and a bottom tool (known as a V-die). Sheet metal bending is a fundamental forming process that alters the geometry of a metal sheet or panel by creating angular changes along a linear axis.

Here are some ways to increase the structural strength of flat sheet stock without adding gussets or increasing the weight of the product. If a panel must be extremely rigid and non-flexible, beading is a better option for bracing.

maximum thickness sheet metal bending

how to use bead roller

bending sheet metal 90 degrees

$23.89

beading in sheet metal|beading process in sheet metal