ab tech cnc machining This course introduces the manual programming, setup, and operation of CNC machining centers. Topics include programming formats, control functions, program editing, part production, and .

Deep drawing is a processing method that uses a drawing die to press the flat blank into various open hollow parts or process the manufactured hollow parts into other shapes of hollow parts under the pressure of a press. The mold for deep drawing is been called deep drawing die. Types of deep drawing parts.

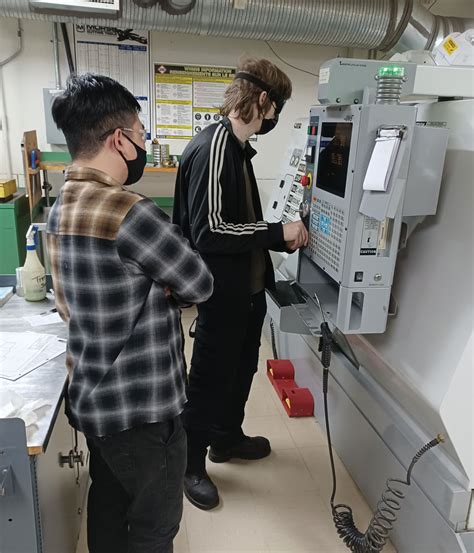

0 · nbcc cnc program

1 · nbcc cnc machine

2 · cnc machine program

Computer Numerical Control (CNC) machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and .

nbcc cnc program

The Computer-Integrated Machining Technology curriculum is designed to prepare students with the analytical, creative, and innovative skills necessary to take a production idea from an initial .This course introduces the manual programming, setup, and operation of .

ceiling light electrical boxes

This course introduces the manual programming, setup, and operation of .The Advance Machining Operator Certificate program provides a .This course introduces the manual programming, setup, and operation of CNC machining centers. Topics include programming formats, control functions, program editing, part production, and .

This course introduces the manual programming, setup, and operation of CNC machining centers. Topics include programming formats, control functions, program editing, part production, and .In our CNC Machining program, you’ll learn the skills needed to bring design ideas to life. We’ll teach you how to program, set-up, troubleshoot, and operate advanced machine tools so that .

CNC precision machining is a computer-controlled manufacturing process that focuses on the ability to consistently replicate specific attributes across a large production volume, ensuring that the dimensions and .ABTech’s high-precision air-bearing spindles provide the ultimate performance utilizing a proven and robust design. High stiffness, load capacity, and very low error motion make these spindles ideal for precision machining, grinding, . 5-axis CNC machining represents a groundbreaking leap in manufacturing technology, offering unmatched flexibility and precision. By enabling simultaneous movement .

CNC machining, is a cutting-edge technology revolutionizing the manufacturing industry. With its unmatched precision, efficiency, and versatility, CNC machining is essential for engineers and . AI and machine learning will revolutionize CNC machining in automotive production. Predictive maintenance algorithms will minimize downtime, while dynamic tool path .The Advance Machining Operator Certificate program provides a foundational knowledge in manufacturing and machining operations, print reading, CNC, industrial safety, 5S, Lean .The Computer-Integrated Machining Technology curriculum is designed to prepare students with the analytical, creative, and innovative skills necessary to take a production idea from an initial concept through design, development, and production, resulting in a finished product.

This course introduces the manual programming, setup, and operation of CNC machining centers. Topics include programming formats, control functions, program editing, part production, and inspection. Upon completion, students should be able to manufacture simple parts using CNC machining centers.This course introduces the manual programming, setup, and operation of CNC machining centers. Topics include programming formats, control functions, program editing, part production, and inspection. Upon completion, students should be able to manufacture simple parts using CNC machining centers.In our CNC Machining program, you’ll learn the skills needed to bring design ideas to life. We’ll teach you how to program, set-up, troubleshoot, and operate advanced machine tools so that you’re ready to become a valuable member of any industrial engineering team . CNC precision machining is a computer-controlled manufacturing process that focuses on the ability to consistently replicate specific attributes across a large production volume, ensuring that the dimensions and characteristics of multiple units .

ABTech’s high-precision air-bearing spindles provide the ultimate performance utilizing a proven and robust design. High stiffness, load capacity, and very low error motion make these spindles ideal for precision machining, grinding, single-point diamond turning, and high-precision scanning. 5-axis CNC machining represents a groundbreaking leap in manufacturing technology, offering unmatched flexibility and precision. By enabling simultaneous movement across five axes, these machines streamline production, reduce setup times, and create intricate designs with ease. Here's how 5-axis CNC machines are transforming manufacturing: 1.CNC machining, is a cutting-edge technology revolutionizing the manufacturing industry. With its unmatched precision, efficiency, and versatility, CNC machining is essential for engineers and product developers alike. From aerospace components to custom automotive parts, this innovative process ensures high-quality output and cost-effectiveness.

AI and machine learning will revolutionize CNC machining in automotive production. Predictive maintenance algorithms will minimize downtime, while dynamic tool path optimization and automated quality control systems will enhance efficiency and product consistency.The Advance Machining Operator Certificate program provides a foundational knowledge in manufacturing and machining operations, print reading, CNC, industrial safety, 5S, Lean manufacturing, quality control, and Total Productive Maintenance (TPM) with an emphasis on preventative maintenance.The Computer-Integrated Machining Technology curriculum is designed to prepare students with the analytical, creative, and innovative skills necessary to take a production idea from an initial concept through design, development, and production, resulting in a finished product.This course introduces the manual programming, setup, and operation of CNC machining centers. Topics include programming formats, control functions, program editing, part production, and inspection. Upon completion, students should be able to manufacture simple parts using CNC machining centers.

This course introduces the manual programming, setup, and operation of CNC machining centers. Topics include programming formats, control functions, program editing, part production, and inspection. Upon completion, students should be able to manufacture simple parts using CNC machining centers.In our CNC Machining program, you’ll learn the skills needed to bring design ideas to life. We’ll teach you how to program, set-up, troubleshoot, and operate advanced machine tools so that you’re ready to become a valuable member of any industrial engineering team . CNC precision machining is a computer-controlled manufacturing process that focuses on the ability to consistently replicate specific attributes across a large production volume, ensuring that the dimensions and characteristics of multiple units .ABTech’s high-precision air-bearing spindles provide the ultimate performance utilizing a proven and robust design. High stiffness, load capacity, and very low error motion make these spindles ideal for precision machining, grinding, single-point diamond turning, and high-precision scanning.

5-axis CNC machining represents a groundbreaking leap in manufacturing technology, offering unmatched flexibility and precision. By enabling simultaneous movement across five axes, these machines streamline production, reduce setup times, and create intricate designs with ease. Here's how 5-axis CNC machines are transforming manufacturing: 1.CNC machining, is a cutting-edge technology revolutionizing the manufacturing industry. With its unmatched precision, efficiency, and versatility, CNC machining is essential for engineers and product developers alike. From aerospace components to custom automotive parts, this innovative process ensures high-quality output and cost-effectiveness.

AI and machine learning will revolutionize CNC machining in automotive production. Predictive maintenance algorithms will minimize downtime, while dynamic tool path optimization and automated quality control systems will enhance efficiency and product consistency.

nbcc cnc machine

cnc machine program

cell phone reception in house with metal roof

Junction boxes are highly reliable for outdoor usage. They are water-resistant, so outside weather does not damage them. We need junction boxes for garden lights, outdoor fixtures , and security lighting.

ab tech cnc machining|nbcc cnc machine