cnc lathe machine working principle How Does a CNC Lathe Machine Work? CNC lathe machines are marvels of modern engineering, designed to perform CNC turning with incredible precision. But how do they work? At the heart of a CNC lathe machine is the concept of computer numerical control. This means the machine’s . Our swaging tool and flaring tool combination flares and swages soft or annealed copper and similar materials. Six hardened and plated alloy steel adapters are interchangeable to convert sizes and functions.

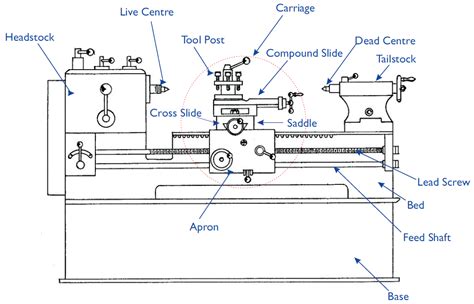

0 · sketch of a lathe machine

1 · simple diagram of lathe machine

2 · parts of lathe machine diagram

3 · operations performed on lathe machine

4 · lathe machine specification with diagram

5 · lathe machine schematic diagram

6 · labelled diagram of lathe machine

7 · block diagram of lathe machine

A yellow box with crisscross lines in the junction indicates a yellow box junction. this tutorial is following the red car turning right on the yellow box. If your driving test involves the use of box junctions, you will need to approach them exactly the same as any other junction by using the MSPSL routine , in this case, for Turning right at .

How Does a CNC Lathe Machine Work? CNC lathe machines are marvels of modern engineering, designed to perform CNC turning with incredible precision. But how do they work? At the heart of a CNC lathe machine is the concept of computer numerical control. This means the machine’s .How CNC Lathes Work. At the core of a CNC lathe is a computer program, often .CNC (Computer Numerical Control) lathe machines have revolutionized the manufacturing industry with their precision, efficiency, and versatility. In this blog post, we will delve into the .

How CNC Lathes Work. At the core of a CNC lathe is a computer program, often written in G-code. This code directs the machine’s movements, controlling everything from the speed of the .

Fig 2: Working Principle of CNC machine. The process of CNC machining involves several integral components working seamlessly in tandem. Initially, the part program is input into the MCU (Machine Control Unit) of the .CNC lathe machines operate on CNC programming principles, automated tool movement and positioning, material removal process, and precision machining. These principles enable the machine to produce high-quality components .

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how .

CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry, enabling precise and efficient production of complex parts. In this blog post, we will delve into . In this article, we will explore the basics of CNC lathe machines and how they operate to produce high-quality components. From the computer-aided design (CAD) software to the actual machining process, we’ll take you .A CNC lathe machine is normally used to produce precise round shapes with both an Outer Diameter (OD), and an Inner Diameter (ID). Practically all kinds of structures could be machined with this machine tool, depending on their .

How Does a CNC Lathe Machine Work? CNC lathe machines are marvels of modern engineering, designed to perform CNC turning with incredible precision. But how do they work? At the heart of a CNC lathe machine is the concept of computer numerical control. This means the machine’s movements are directed by coded instructions, usually written in G-code. In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.CNC (Computer Numerical Control) lathe machines have revolutionized the manufacturing industry with their precision, efficiency, and versatility. In this blog post, we will delve into the world of CNC lathe machines, explaining their working principles, applications, benefits, and .

How CNC Lathes Work. At the core of a CNC lathe is a computer program, often written in G-code. This code directs the machine’s movements, controlling everything from the speed of the spindle to the position of the cutting tool. The process begins with a CAD (Computer-Aided Design) drawing, which is translated into G-code. This code is then . Fig 2: Working Principle of CNC machine. The process of CNC machining involves several integral components working seamlessly in tandem. Initially, the part program is input into the MCU (Machine Control Unit) of the CNC system.CNC lathe machines operate on CNC programming principles, automated tool movement and positioning, material removal process, and precision machining. These principles enable the machine to produce high-quality components efficiently with accuracy and consistency.

The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at .CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry, enabling precise and efficient production of complex parts. In this blog post, we will delve into the working principle of CNC machines and explore how they have transformed various industries.

In this article, we will explore the basics of CNC lathe machines and how they operate to produce high-quality components. From the computer-aided design (CAD) software to the actual machining process, we’ll take you through every step of the way.A CNC lathe machine is normally used to produce precise round shapes with both an Outer Diameter (OD), and an Inner Diameter (ID). Practically all kinds of structures could be machined with this machine tool, depending on their needs in different industries.How Does a CNC Lathe Machine Work? CNC lathe machines are marvels of modern engineering, designed to perform CNC turning with incredible precision. But how do they work? At the heart of a CNC lathe machine is the concept of computer numerical control. This means the machine’s movements are directed by coded instructions, usually written in G-code. In this article, you'll learn what is CNC machine with its working principle, basic elements, types, advantages, applications and PDF.

CNC (Computer Numerical Control) lathe machines have revolutionized the manufacturing industry with their precision, efficiency, and versatility. In this blog post, we will delve into the world of CNC lathe machines, explaining their working principles, applications, benefits, and .How CNC Lathes Work. At the core of a CNC lathe is a computer program, often written in G-code. This code directs the machine’s movements, controlling everything from the speed of the spindle to the position of the cutting tool. The process begins with a CAD (Computer-Aided Design) drawing, which is translated into G-code. This code is then . Fig 2: Working Principle of CNC machine. The process of CNC machining involves several integral components working seamlessly in tandem. Initially, the part program is input into the MCU (Machine Control Unit) of the CNC system.

CNC lathe machines operate on CNC programming principles, automated tool movement and positioning, material removal process, and precision machining. These principles enable the machine to produce high-quality components efficiently with accuracy and consistency.The CNC machine process is a highly automated technical program that combines computer numerical control with precision machine tooling. Learn what a CNC machine is and how automated CNC machining works to increase productivity, safety and efficiency at .CNC (Computer Numerical Control) machines have revolutionized the manufacturing industry, enabling precise and efficient production of complex parts. In this blog post, we will delve into the working principle of CNC machines and explore how they have transformed various industries.

In this article, we will explore the basics of CNC lathe machines and how they operate to produce high-quality components. From the computer-aided design (CAD) software to the actual machining process, we’ll take you through every step of the way.

sketch of a lathe machine

simple diagram of lathe machine

parts of lathe machine diagram

Since its beginning in 1990, Yarl Metal has grown several times and established itself as a leading supplier of metal fabrication products having state-of-the-art facilities supported by a highly experienced engineering team.

cnc lathe machine working principle|parts of lathe machine diagram