when was sheet metal invented • "Manufacturers Standard Gauge History". Steel Market Update. Archived from the original on 2013-09-28. Retrieved 2013-06-19.• "Sheet Steel Gauges and Thicknesses" (PDF). Sheet Steel Facts. Sachiya Steel International. . See more Remove the retaining strap off the tab (you can see the tab in your picture) by using your thumb to push down on the strap (toward the tab) and you will be able to unhook it. Reassemble by .

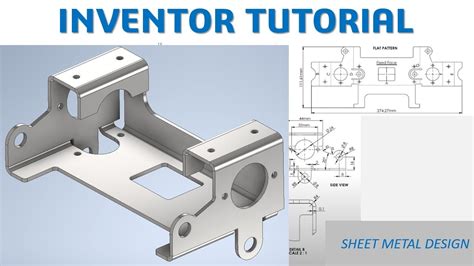

0 · sheet metal inventor tutorial pdf

1 · sheet metal inventor tutorial

2 · sheet metal drawing in inventor

3 · inventor unfold sheet metal

4 · inventor sheet metal thickness

5 · inventor sheet metal flat pattern

6 · inventor convert to sheet metal

7 · inventor change sheet metal thickness

This Parmida LED Slim Panel Downlight is an ultra-thin recessed downlight with a remote driver junction box for quick, simple, and housing free installations. Its low-profile design makes it the ideal solution for new construction or remodel projects without the requirement of a housing can.

Hand-hammered metal sheets have been used since ancient times for architectural purposes. Water-powered rolling mills replaced the manual process in the late 17th century. The process of flattening metal sheets required large rotating iron cylinders which pressed metal pieces into sheets. The metals suited for . See more

Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered . See moreBendingThe equation for estimating the maximum bending force is,$${\displaystyle F_{\text{max}}=k{\frac {TLt^{2}}{W}}}$$,where k is a factor taking into account several parameters . See moreFasteners that are commonly used on sheet metal include: clecos, rivets, and sheet metal screws. See more

• "Manufacturers Standard Gauge History". Steel Market Update. Archived from the original on 2013-09-28. Retrieved 2013-06-19.• "Sheet Steel Gauges and Thicknesses" (PDF). Sheet Steel Facts. Sachiya Steel International. . See moreStainless steelGrade 304 is the most common of the three grades. It offers good corrosion resistance while . See moreThe use of sheet metal, through a comprehensive cold working process, including bending, shearing, punching, laser cutting, water jet cutting, riveting, splicing, etc. to make the final product we want (such as computer chassis, washing machine shells, . See more• Circle grid analysis• Corrugated galvanised iron, also known as Corrugated Sheet Metal• Diamond plate• Forming limit diagram See more

Fundamental was, in 1857, the introduction of the Bessemer converter (Figure 1) used in the industrial production of steel starting from the . By 1851, sheet metal production was underway in America and Europe on a large scale. A 6 meter long and 11 millimeter thick piece of sheet metal was displayed at the British Great Expedition. It would signify the .How was sheet metal made in ancient times? Sheet metal making dates back to the times of ancient Egypt, where they crafted metal into various shapes. The process involved hammering metal into sheets, after which they would be .

1) Sheet metal fabrication has ancient origins. The ancient Egyptians are credited with developing the first sheet metal, which they used to create jewelry. Ashley Van Haeften / CC BY-SA. The ancient Egyptians first .The first known use of sheet metal dates back to 4000 BC when it was used to create swords in ancient Mesopotamia. Then, around 1000 BC, Chinese metallurgists began using a process .This history began over 80,000 years ago and leads to the industrial production of sheet metal made of complex alloys.At a very primitive state, sheet metal working started through the cold use of metals present in nature like gold and silver. Once the possibility of melting came into realization, bronze, copper and most recently steel were introduced into .

An historic overview of the sheet metal fabrication process. You may think that the term ‘sheet metal fabrication’ sounds modern, conjuring up thoughts of advanced manufacturing. .

What's sheet metal made of? A versatile material that is used in a variety of applications, sheet metal can be made of a wide range of materials. Whether it is made of copper or stainless steel, the process of making sheet metal is very similar and involves melting, cleaning and rolling the metal.Parts made from sheet metal must maintain a consistent thickness for best results. Related: 1. What is Ferrous Metal? 2. What is Non-Ferrous Metal? Many different metals can be used in sheet metal manufacturing such as aluminum, .Sheet metal is metal formed into thin, flat pieces, usually by an industrial process.. Sheets of Nirosta stainless steel cover the Chrysler Building. Microscopic close-up of mild steel sheet metal. Thicknesses can vary significantly; extremely thin sheets are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered plate, such as plate steel, a class of structural steel.

sheet metal inventor tutorial pdf

When was chrome plating invented? It was first developed in 1924, marking a significant advancement in surface finishing techniques that revolutionized many. . positions him as a key influencer shaping the future of the sheet metal fabrication industry. View AuthorUnit 6, No. 6, Sixth Street Montague Gardens Cape Town . [email protected]. Tel: 021-552 7750 Cell: 076-890 8355 Fax: 086-554 6701

Relative to some other industries, sheet metal bending really isn’t all that old. Manufacturing and production using sheet metal components largely took off in the late 19 th century during the Industrial Revolution. Using the newly developed concept of the assembly line and machines like press brakes, fabricators could produce more parts in .

Roman works used sheet metal on roofs and to line baths. Sheet copper metal ornament is present in Versailles as early as the 17th century. In North America, sheet metal emerged in the 19th century as a common building material, initially supplied by England, until rolling mills were established in post-Revolutionary War America.Corrugated galvanised iron (CGI) or steel, colloquially corrugated iron (near universal), wriggly tin (taken from UK military slang), pailing (in Caribbean English), corrugated sheet metal (in North America), zinc (in Cyprus and Nigeria) or custom orb / corro sheet (Australia), is a building material composed of sheets of hot-dip galvanised . Measuring and gauging wire and sheet metal "The early business of J. R. Brown & Sharpe connected them closely with the various standards then in use for measuring wire, sheet metal, and the like. Mr. Sharpe was impressed with the irregularity and confusion of these various gauges, so that after he became Mr. Brown's partner, he interested himself in the .

Parts with conical faces can also be made of sheet metal. To create a sheet metal part with conical faces: . However, sheet metal parts created with the Lofted Bends feature avoid this limitation and unfold appropriately. Parent topicInsert Bends Tool. Creating a Sheet Metal Part Using Sharp Bends. Creating a Sheet Metal Part Using Round Bends. American-Made Sheet Metal Prototyping and Metal Fabrication. Last updated on March 4th, 2024 at 12:05 pm. At Approved Sheet Metal (ASM), we’re proud that 100% of our parts are made in the USA (more specifically, made in the great town of Hudson, New Hampshire).. The assumption is often that American products are expensive compared to overseas resources, .In its simplest form, sheet metal is a thin, flat piece made from the more prominent metal roll. The metal sheet is uniformly thin, no more than 6mm thick. This makes it flexible and ideal for different manipulation techniques. Metal sheets come in many other materials, such as stainless, aluminum, brass, and copper. Each material has its .

As for the modern-day fasteners, they were only invented in the 18th century, with mass production starting in 1760. And in the early 20th century, the Phillips head screws were made. Yes, screws have been a long time in the making, and in this guide, we’ll talk about the history of the screw in great detail. . Sheet metal screws. For .Study with Quizlet and memorize flashcards containing terms like An extremely large machine for producing sheet metal from steel ingots would be classified as which type of support product?, Which of the following is the best example of a convenience product?, A newly-invented apple peeling and coring machine for the consumer market would be considered an and more. Galvanized steel has become a preferred construction material because of lower initial cost, lower maintenance costs, ease of inspection, faster construction time, and complete protection of structural elements. Galvanized .For thin sheet metal with a thickness less than 200 μm (0.0079 in), [citation needed] . To resolve this, the three-high mill was invented, which uses three rolls that rotate in one direction; the metal is fed through two of the rolls and then returned through the other pair. The disadvantage to this system is the workpiece must be lifted and .

Shop for steel sheet at America's Metal Superstore. Largest selection of Hot Rolled Steel Sheet, Cold Rolled Steel Sheet, Galvanized Steel Sheet at wholesale prices. Any Quantity, Any Size, Delivered Anywhere! Select Size; 1 .

sheet metal inventor tutorial

control box for electric motors

The thickness of the metal is uniform because the rollers are set to produce that thickness, so modern sheet metal has a series of very narrowly defined thicknesses (measured in 'gauge' - the area of a plate required to make a pound, lower is thicker -, or in metric measurements, generally millimeters and fractions therof).

6 Inch Hand Seamers Sheet Metal Tools - Straight Jaw Sheet Metal Hand Brake Bender Tools - Flattening Metal Made Easy - Ergonomic Handle - Durable and Reliable . Our 6 inch hand seamers sheet metal tools ergonomically contoured handle The handle is made of A3 steel material, the handle ensures comfortable use and brings you comfort.The larger the gauge number, the thinner the metal. Commonly used steel sheet metal ranges from 30 gauge to about 7 gauge. Gauge differs between ferrous (iron-based) metals and nonferrous metals such as aluminum or copper. Many different metals can be made into sheet metal, such as aluminium, brass, copper, steel, tin, nickel and titanium. As the application of sheet metal continues to expand, the design of sheet metal parts has become a critical aspect of product development. Mechanical engineers must be well-versed in the design of sheet metal components to ensure that the parts meet the necessary functional and aesthetic requirements while keeping the stamping die production .The Tesla Cybertruck is a battery electric full-size pickup truck built by Tesla, Inc. since 2023. The vehicle was introduced as a concept vehicle in.

The Earliest Uses of Sheet Metal Work. The first known use of sheet metal dates back to 4000 BC when it was used to create swords in ancient Mesopotamia. Then, around 1000 BC, Chinese metallurgists began using a process known as annealing to make weapons and tools from iron and steel. This process made the metal softer and more pliable, which . Housings and enclosures for medical equipment and devices are often made via sheet metal forming as this process meets the industry’s strict standards and regulations. The process is used a whole lot in construction for things like beams, columns, brackets, long-lasting and weather-resistant roofing sheets, and ductwork for HVAC systems. . Sheet metal ducts are ducts made from sheet metal plates, mostly galvanized steel, although they are also made of stainless steel, copper, and aluminum. Generally, they are prefabricated and formed in different formats according to the use to which they will be destined. There are circular, rectangular, and even oval ducts.

Find many great new & used options and get the best deals for Vintage Tin Snips Sheet Metal Cutting Shears USA Made Solid Steel at the best online prices at eBay! Free shipping for many products!

Fig.: Bending specs for 0.040” 5052 Aluminum. Bend Length. The bend length, or width of the flange, is dependent on, wait for it, the material properties: For the 304 Stainless in the previous example, the maximum length is 36” while a thinner, more ductile material like the the 5052 aluminum can easily be bent all the way up to the max part size of 44”.

cookeville sheet metal

sheet metal drawing in inventor

Key Features of Fibox Junction Boxes: UL Listed and Certified: Ensures compliance with safety standards for electrical applications. Fire Retardant Properties: Polycarbonate offers inherent fire resistance for added peace of .

when was sheet metal invented|sheet metal inventor tutorial