classification of cnc lathe machine In this section, based on this classification, we will explore different types of CNC machines, their respective uses, and the limitations of each type. 1. CNC Router. A CNC router is a machine that shares similarities with a CNC mill.

CNC machine inserts play a vital role in ensuring the efficiency and effectiveness of CNC machines. Understanding the different types of inserts and their specific applications can help .

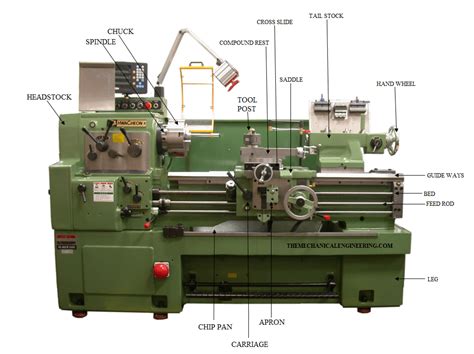

0 · type of lathe machine

1 · specification of lathe machine

2 · special purpose lathe machine drawing

3 · lathe machine types pdf

4 · lathe machine specification with diagram

5 · figure of lathe machine

6 · different types of lathe machine

7 · diagram of lathe machine

Types of Heat Treatment Processes. Heat treatment encompasses various processes, each tailored to achieve specific results in altering the properties of metals. Hardening. The primary purpose of hardening is to increase the hardness and strength of metals.

Select the right CNC lathe for efficient machining. . A CNC turning machine, also known as a CNC lathe, is an automated machine used in precision machining. These machines work with cylindrical workpieces, rotating them while cutting tools shape the material into the desired . There are two guideways provided, inner ways and outer ways, which are accurately machined to make them parallel to the axis. The lathe should take up the various .

According to the function or type of CNC machining parts, CNC machining machine tools can be divided into five types: CNC milling machine, CNC lathe, CNC drilling machine, CNC plasma cutting machine and CNC .

vintage metal boxes

CNC Lathe Machine. Turning employs single-point cutting tools to remove material from the rotating workpiece. The design of the turning tool varies based on the particular application, with tools available for roughing, finishing, .According to the functions or types of machined parts, CNC machines can be classified into five types: CNC milling machines, CNC lathes, CNC drilling machines, CNC plasma cutters, and CNC grinders.In this section, based on this classification, we will explore different types of CNC machines, their respective uses, and the limitations of each type. 1. CNC Router. A CNC router is a machine that shares similarities with a CNC mill.CNC machining can be classified into different categories based on the scope of application and complexity of the parts produced. The most common classifications include: - CNC Lathe Machining: This technique rotates the .

Select the right CNC lathe for efficient machining. . A CNC turning machine, also known as a CNC lathe, is an automated machine used in precision machining. These machines work with cylindrical workpieces, rotating them while cutting tools shape the material into the desired form. . Comprehensive Classification of CNC Turning Machines

type of lathe machine

Explore our range of CNC Lathe Machines & Turning Centres. The different types of CNC lathe can be determined by the number of movement axes: 2-axis – can perform outer/inner diameter machining, facing, drilling, and tapping. 4-axis – typically adds a second tool carrier or turret. There are 15 different types of CNC machines, each with their own unique capabilities. The most common types include milling machines, lathes, routers, and grinders. These are the 15 types of CNC I’ll cover in this article: CNC router machine; CNC mills; CNC lathe machines; Wire EDM; EDM; CNC laser cutting machine; CNC grinders; CNC plasma .

Following are the types of CNC machine: 1. CNC Lathe Machine. Lathe CNC machines are defined by their capability to turn materials during operation. They have less number of axes than CNC milling machines, making them shorter and more compact. There are two guideways provided, inner ways and outer ways, which are accurately machined to make them parallel to the axis. The lathe should take up the various vibrations, which are causing due to different types of force. The guideways provide sliding surfaces to the carriage and the tailstock.

According to the function or type of CNC machining parts, CNC machining machine tools can be divided into five types: CNC milling machine, CNC lathe, CNC drilling machine, CNC plasma cutting machine and CNC grinder.

CNC Lathe Machine. Turning employs single-point cutting tools to remove material from the rotating workpiece. The design of the turning tool varies based on the particular application, with tools available for roughing, finishing, facing, threading, forming, undercutting, parting, and grooving applications.According to the functions or types of machined parts, CNC machines can be classified into five types: CNC milling machines, CNC lathes, CNC drilling machines, CNC plasma cutters, and CNC grinders.

In this section, based on this classification, we will explore different types of CNC machines, their respective uses, and the limitations of each type. 1. CNC Router. A CNC router is a machine that shares similarities with a CNC mill.

CNC machining can be classified into different categories based on the scope of application and complexity of the parts produced. The most common classifications include: - CNC Lathe Machining: This technique rotates the workpiece while a cutting tool removes material, resulting in cylindrical or rotational parts.Select the right CNC lathe for efficient machining. . A CNC turning machine, also known as a CNC lathe, is an automated machine used in precision machining. These machines work with cylindrical workpieces, rotating them while cutting tools shape the material into the desired form. . Comprehensive Classification of CNC Turning MachinesExplore our range of CNC Lathe Machines & Turning Centres. The different types of CNC lathe can be determined by the number of movement axes: 2-axis – can perform outer/inner diameter machining, facing, drilling, and tapping. 4-axis – typically adds a second tool carrier or turret.

There are 15 different types of CNC machines, each with their own unique capabilities. The most common types include milling machines, lathes, routers, and grinders. These are the 15 types of CNC I’ll cover in this article: CNC router machine; CNC mills; CNC lathe machines; Wire EDM; EDM; CNC laser cutting machine; CNC grinders; CNC plasma . Following are the types of CNC machine: 1. CNC Lathe Machine. Lathe CNC machines are defined by their capability to turn materials during operation. They have less number of axes than CNC milling machines, making them shorter and more compact.

vintage metal angle brackets

There are two guideways provided, inner ways and outer ways, which are accurately machined to make them parallel to the axis. The lathe should take up the various vibrations, which are causing due to different types of force. The guideways provide sliding surfaces to the carriage and the tailstock. According to the function or type of CNC machining parts, CNC machining machine tools can be divided into five types: CNC milling machine, CNC lathe, CNC drilling machine, CNC plasma cutting machine and CNC grinder. CNC Lathe Machine. Turning employs single-point cutting tools to remove material from the rotating workpiece. The design of the turning tool varies based on the particular application, with tools available for roughing, finishing, facing, threading, forming, undercutting, parting, and grooving applications.According to the functions or types of machined parts, CNC machines can be classified into five types: CNC milling machines, CNC lathes, CNC drilling machines, CNC plasma cutters, and CNC grinders.

In this section, based on this classification, we will explore different types of CNC machines, their respective uses, and the limitations of each type. 1. CNC Router. A CNC router is a machine that shares similarities with a CNC mill.

specification of lathe machine

special purpose lathe machine drawing

vintage cannon split housing mil spec screw connector metal

lathe machine types pdf

Cutting inserts are divided into different types. This division specifically relates to the material they are made, its shape, dimensions, and applications. The most common are turning inserts, groove-turning inserts, inserts for cutting hard materials, and thread-turning inserts.

classification of cnc lathe machine|type of lathe machine