coining sheet metal Coining produces finer details and provides a smooth surface finish to the metal work piece. Coining can be done using a gear driven press, a hydraulic press, or a mechanical press. Lubricants are not used in coining as they are .

Viking Steel Structures offer a versatile range of quality Prefab Steel Buildings across the US. You can directly call our metal building specialists at 877-801-3263 or surf our diverse catalog to choose the one that suits your requirements.

0 · sheet metal process in impl

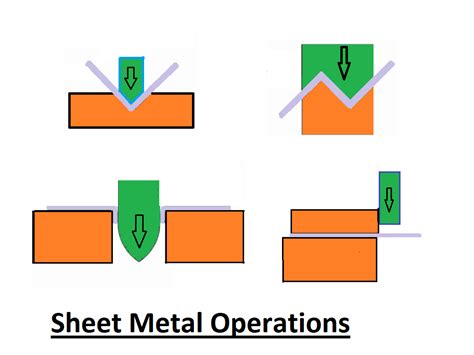

1 · sheet metal operations with diagrams

2 · sheet metal coining process

3 · restrike process in sheet metal

4 · lancing process in sheet metal

5 · design for manufacturing sheet metal

6 · defects in sheet metal operation

7 · coining process in metal stamping

Westech Metal Fabrication Inc. opened for business in 1993 building a wide range of custom metal products from a 1000 sq ft leased building here in San Diego. Since then, we have migrated through several buildings to our present 18,000 sq ft complex.

sheet metal process in impl

Coining fabrication is a basic type of bending in which the workpiece is stamped between the punch and die. Both the punch tip and the punch actually penetrate into the metal past the neutral axis under a high amount of pressure. In this video, I will introduce you to coining sheet metal. We will not be making coins but, that’s where the name comes from. Coining metal is the process o.

steel box channel size chart

Coining is a form of precision stamping in which a workpiece is subjected to a sufficiently high stress to induce plastic flow on the surface of the material. A beneficial feature is that in some metals, the plastic flow reduces surface grain size, and work hardens the surface, while the material deeper in the part retains its toughness and ductility. The term comes from the initial use of the process: manufacturing of coinsexpensive sheet metal, slow, very high formability Technology – a brief review Forming Speed 20-1000pts/hr 7-13cycles/hr 3-8pts/hr . • “coining” or bottoming the punch . Pure Bending . In the same vein, “coining” with a press brake (Fig. 1a) involves using enough tonnage to conform the sheet metal to the exact angle of the punch and die being used. In .

Coining produces finer details and provides a smooth surface finish to the metal work piece. Coining can be done using a gear driven press, a hydraulic press, or a mechanical press. Lubricants are not used in coining as they are .Metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece. Coining may be used to control surface quality and detail on parts. Metal coining is often a finishing process for .

Coining is a process in which the metal is compressed or squeezed into the desired shape or profile. The coins that you have in your pocket are a classic example of items made by coining. Coining has several .Coining in sheet metal involves bending a sheet metal workpiece using a punch and die such that the Punch penetrates the sheet metal part. In this way, coining gives highly accurate and precise sheet metal parts.Coining fabrication is a basic type of bending in which the workpiece is stamped between the punch and die. Both the punch tip and the punch actually penetrate into the metal past the neutral axis under a high amount of pressure.

In this video, I will introduce you to coining sheet metal. We will not be making coins but, that’s where the name comes from. Coining metal is the process o.Coining is a form of precision stamping in which a workpiece is subjected to a sufficiently high stress to induce plastic flow on the surface of the material. Coins (metal currency) are created with the coining process. A simple round metal slug is placed into the die and forced to flow into a given shape by compressing it (see Figure 3). The restrike die operation fundamentally is a solid forming operation.expensive sheet metal, slow, very high formability Technology – a brief review Forming Speed 20-1000pts/hr 7-13cycles/hr 3-8pts/hr . • “coining” or bottoming the punch . Pure Bending Bending & Stretching σ h -Y Fully plastic σ h Y Fully plastic Y Y tension compression .

In the same vein, “coining” with a press brake (Fig. 1a) involves using enough tonnage to conform the sheet metal to the exact angle of the punch and die being used. In coining, the sheet metal is more than just bent, it is actually thinned by the impact of the punch and die, as it is compressed between them along the bending surfaces (Fig .Coining produces finer details and provides a smooth surface finish to the metal work piece. Coining can be done using a gear driven press, a hydraulic press, or a mechanical press. Lubricants are not used in coining as they are incompressible.Metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece. Coining may be used to control surface quality and detail on parts. Metal coining is often a finishing process for manufactured products. Coining is a process in which the metal is compressed or squeezed into the desired shape or profile. The coins that you have in your pocket are a classic example of items made by coining. Coining has several advantages and disadvantages.

Coining in sheet metal involves bending a sheet metal workpiece using a punch and die such that the Punch penetrates the sheet metal part. In this way, coining gives highly accurate and precise sheet metal parts.Coining fabrication is a basic type of bending in which the workpiece is stamped between the punch and die. Both the punch tip and the punch actually penetrate into the metal past the neutral axis under a high amount of pressure.In this video, I will introduce you to coining sheet metal. We will not be making coins but, that’s where the name comes from. Coining metal is the process o.

Coining is a form of precision stamping in which a workpiece is subjected to a sufficiently high stress to induce plastic flow on the surface of the material. Coins (metal currency) are created with the coining process. A simple round metal slug is placed into the die and forced to flow into a given shape by compressing it (see Figure 3). The restrike die operation fundamentally is a solid forming operation.expensive sheet metal, slow, very high formability Technology – a brief review Forming Speed 20-1000pts/hr 7-13cycles/hr 3-8pts/hr . • “coining” or bottoming the punch . Pure Bending Bending & Stretching σ h -Y Fully plastic σ h Y Fully plastic Y Y tension compression . In the same vein, “coining” with a press brake (Fig. 1a) involves using enough tonnage to conform the sheet metal to the exact angle of the punch and die being used. In coining, the sheet metal is more than just bent, it is actually thinned by the impact of the punch and die, as it is compressed between them along the bending surfaces (Fig .

Coining produces finer details and provides a smooth surface finish to the metal work piece. Coining can be done using a gear driven press, a hydraulic press, or a mechanical press. Lubricants are not used in coining as they are incompressible.Metal coining is a forging process by which very fine and intricate details can be created on the surface of a work piece. Coining may be used to control surface quality and detail on parts. Metal coining is often a finishing process for manufactured products. Coining is a process in which the metal is compressed or squeezed into the desired shape or profile. The coins that you have in your pocket are a classic example of items made by coining. Coining has several advantages and disadvantages.

sheet metal operations with diagrams

sheet metal coining process

steel ammo box usa

restrike process in sheet metal

This listing is for a Western Electric WE KS-14703 755A Speaker in Original WE Cabinet with WE speaker Transformer. The speaker is in good working condition and sounds quite nice. The measured DCR is 2.3 ohms. The cosmetics of both the speaker and cabinet can be seen in the many pictures taken.

coining sheet metal|defects in sheet metal operation