different types of sheet metal forming processes In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, . At Northwest Steel Fab Inc., we’re your premier destination for custom metal fabrication and coating solutions. With a track record of precision and excellence, we specialize in crafting .

0 · sheet metal working process pdf

1 · sheet metal stamping process pdf

2 · sheet metal processes pdf

3 · sheet metal forming process pdf

4 · sheet metal forming press dies

5 · sheet metal forming by hand

6 · sheet metal bending process pdf

7 · bulk deformation vs sheet metal forming

High quality BXJ8050-20/6 Series Explosion Proof Junction Boxes Stainless Steel IP65 Flameproof from China, China's leading ip65 explosion proof junction boxes product, with strict quality control flameproof explosion proof electrical junction box factories, producing high quality stainless steel ex proof junction box products.

Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different . In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, . In this article, we will cover 19 different operations you can use to fabricate your metal parts. Let’s dive right in: 1. Rolling Metal. In the fabrication sector, rolling metal is among the most often used techniques. This procedure .Learn about the different types of metal forming processes such as bending, roll forming, and more. Click here!

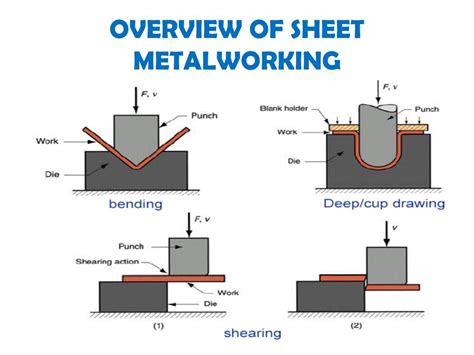

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing. Shearing is . The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form . Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different processes and equipment, which we’ll cover a . Based upon the manufactured components and the manufacturing process, various kinds of forming are developed. Different types of sheet metal forming processes and their applications and characteristics are discussed below: Roll forming; In this process the sheet metal is passed through a large numbers of set of rollers continuously. The each .

In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, advancements, applications, and more. In this article, we will cover 19 different operations you can use to fabricate your metal parts. Let’s dive right in: 1. Rolling Metal. In the fabrication sector, rolling metal is among the most often used techniques. This procedure will be .Learn about the different types of metal forming processes such as bending, roll forming, and more. Click here! However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing. Shearing is similar to what the name suggests—cutting through a sheet of metal in a straight line or curve.

Metal forming is a process of manufacturing components of desired shapes by deforming the material plastically, by the application of compressive force, bending or shear force, tensile force, or combinations of these all forces together, without adding or removing material. Sheet metal forming, encompassing techniques such as bending, stretching, and deep drawing, plays a pivotal role in creating lightweight yet durable components essential for modern engineering applications.

Metal punching, extrusion, press braking, rolling, forging and laser cutting are some of the more common forming processes. Here are more details on each technique: Common Types of Forming. The most common metal . The process of producing sheet metal components using metal sheets is known as sheet metal forming or sheet metal fabrication. This is accomplished by bending, punching, shearing, hydroforming, and other techniques to form . Also known as sheet metal fabrication, sheet metal forming uses metal sheets to make various products and components. The metal sheets are formed and cut into the necessary shape and size via many different processes and equipment, which we’ll cover a . Based upon the manufactured components and the manufacturing process, various kinds of forming are developed. Different types of sheet metal forming processes and their applications and characteristics are discussed below: Roll forming; In this process the sheet metal is passed through a large numbers of set of rollers continuously. The each .

In this comprehensive guide, we will explore different types of sheet metal forming processes, materials used, design considerations, tooling and equipment, process steps, quality control, troubleshooting, advancements, applications, and more. In this article, we will cover 19 different operations you can use to fabricate your metal parts. Let’s dive right in: 1. Rolling Metal. In the fabrication sector, rolling metal is among the most often used techniques. This procedure will be .Learn about the different types of metal forming processes such as bending, roll forming, and more. Click here!

However, there are two categories of sheet metal operations: cutting and forming. Under the two subcategories, there are nine other processes that make up sheet metal operations as a whole. 1. Shearing. Shearing is similar to what the name suggests—cutting through a sheet of metal in a straight line or curve. Metal forming is a process of manufacturing components of desired shapes by deforming the material plastically, by the application of compressive force, bending or shear force, tensile force, or combinations of these all forces together, without adding or removing material. Sheet metal forming, encompassing techniques such as bending, stretching, and deep drawing, plays a pivotal role in creating lightweight yet durable components essential for modern engineering applications.

miniature corrugated metal sheets

sheet metal working process pdf

sheet metal stamping process pdf

sheet metal processes pdf

Warren County Sheet Metal is a reputable company based in Bowling Green, KY, specializing in the fabrication and installation of custom sheet metal products. With a focus on quality craftsmanship and attention to detail, they cater to both residential and commercial clients.

different types of sheet metal forming processes|bulk deformation vs sheet metal forming