cnc machine operation ppt This web page contains a presentation on CNC machines, their history, components, advantages, and programming methods. It also covers the differences between . Search our network of job shops and contract manufacturers. Injection .

0 · cnc machine tools ppt

1 · cnc machine ppt template

2 · cnc machine ppt download

3 · cnc machine maintenance ppt

4 · cnc lathe machine working ppt

5 · cnc lathe machine ppt download

6 · cnc drilling machine pdf

7 · basics of cnc machine ppt

What size screws should I use for cabinet doors? It is recommended to use #6 or #8 screws that are 1 1/4 inches long for cabinet doors. Can I use shorter screws for cabinets?

This web page contains a presentation on CNC machines, their history, components, advantages, and programming methods. It also covers the differences between .This presentation summarizes the key characteristics of CNC machines. It .CNC milling machines use computerized controls and rotating cutting tools to .

This document provides an overview of CNC programming and operation skills .

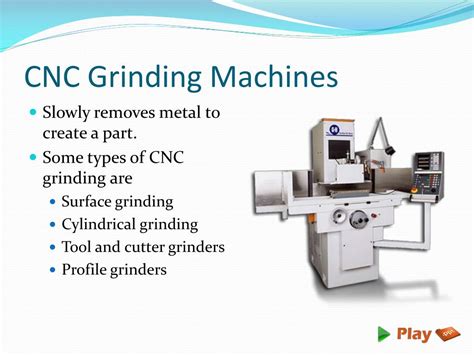

This presentation summarizes the key characteristics of CNC machines. It describes how CNC machines are automated machine tools controlled by programmed commands stored on a computer. The history of . CNC milling machines use computerized controls and rotating cutting tools to remove material from a workpiece. There are two main types - horizontal and vertical milling machines - classified based on the orientation of . Introduction • CNC (Computer Numerical Control) Machines are automated machines, which uses programs to automatically execute a series of machining operations. • .

3 objectives List the steps to set up and operate CNC Mill. Identify location and purpose of operating controls on CNC mill controller. Start and Home CNC mill. Load tools into CNC mill. . Introduction to CNC. Presented By Bidve M.A. Introduction. Conventionally machines were operated by skilled technician(operator) who determines the various variables like speed, feed, depth of cut, etc. for .- CNC machines are electro-mechanical devices that manipulate machine shop tools using computer programming inputs. Let's find out what CNC Machines are and its types. Read: http://www.hatfieldmachinery.com/ | PowerPoint PPT . This document provides an overview of CNC programming and operation skills training at the Government Tool Room and Training Centre in Hassan. It introduces the GTTC and its facilities for CAD/CAM and advanced .

Large cnc milling machine with custom cnc machining services. CNC Machining: It is a process to manufacturing of high precision parts which required to be produced with high specifications. CNC machining works great .

cnc machine tools ppt

CNC (Computer Numerically Controlled) machines allow for precise and repeatable machining operations through computerized control programs, with CNC lathes, milling machines, and other tools controlled by numerically coded . The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions.

nx sheet metal drawing

This presentation summarizes the key characteristics of CNC machines. It describes how CNC machines are automated machine tools controlled by programmed commands stored on a computer. The history of CNC is outlined from its origins in the 1950s to become widely used today. CNC milling machines use computerized controls and rotating cutting tools to remove material from a workpiece. There are two main types - horizontal and vertical milling machines - classified based on the orientation of the spindle axis. Introduction • CNC (Computer Numerical Control) Machines are automated machines, which uses programs to automatically execute a series of machining operations. • CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) programs is used in modern CNC machines for end-to-end component design.

3 objectives List the steps to set up and operate CNC Mill. Identify location and purpose of operating controls on CNC mill controller. Start and Home CNC mill. Load tools into CNC mill. Set Tool Length Offset registers. Set Fixture Offset registers. Introduction to CNC. Presented By Bidve M.A. Introduction. Conventionally machines were operated by skilled technician(operator) who determines the various variables like speed, feed, depth of cut, etc. for machining the required component. Slideshow 9013202 by .- CNC machines are electro-mechanical devices that manipulate machine shop tools using computer programming inputs. Let's find out what CNC Machines are and its types. Read: http://www.hatfieldmachinery.com/ | PowerPoint PPT presentation | free to view

cnc machine ppt template

This document provides an overview of CNC programming and operation skills training at the Government Tool Room and Training Centre in Hassan. It introduces the GTTC and its facilities for CAD/CAM and advanced manufacturing techniques. Large cnc milling machine with custom cnc machining services. CNC Machining: It is a process to manufacturing of high precision parts which required to be produced with high specifications. CNC machining works great when you have .

CNC (Computer Numerically Controlled) machines allow for precise and repeatable machining operations through computerized control programs, with CNC lathes, milling machines, and other tools controlled by numerically coded programs to automate cutting, drilling, milling, and other manufacturing processes with improved flexibility, accuracy, and . The key elements of a CNC machine are described as the input device, machine control unit, machine tool, driving system, feedback devices, and display unit. The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions.

This presentation summarizes the key characteristics of CNC machines. It describes how CNC machines are automated machine tools controlled by programmed commands stored on a computer. The history of CNC is outlined from its origins in the 1950s to become widely used today.

CNC milling machines use computerized controls and rotating cutting tools to remove material from a workpiece. There are two main types - horizontal and vertical milling machines - classified based on the orientation of the spindle axis. Introduction • CNC (Computer Numerical Control) Machines are automated machines, which uses programs to automatically execute a series of machining operations. • CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) programs is used in modern CNC machines for end-to-end component design.

3 objectives List the steps to set up and operate CNC Mill. Identify location and purpose of operating controls on CNC mill controller. Start and Home CNC mill. Load tools into CNC mill. Set Tool Length Offset registers. Set Fixture Offset registers. Introduction to CNC. Presented By Bidve M.A. Introduction. Conventionally machines were operated by skilled technician(operator) who determines the various variables like speed, feed, depth of cut, etc. for machining the required component. Slideshow 9013202 by .

- CNC machines are electro-mechanical devices that manipulate machine shop tools using computer programming inputs. Let's find out what CNC Machines are and its types. Read: http://www.hatfieldmachinery.com/ | PowerPoint PPT presentation | free to view

cnc machine ppt download

This document provides an overview of CNC programming and operation skills training at the Government Tool Room and Training Centre in Hassan. It introduces the GTTC and its facilities for CAD/CAM and advanced manufacturing techniques. Large cnc milling machine with custom cnc machining services. CNC Machining: It is a process to manufacturing of high precision parts which required to be produced with high specifications. CNC machining works great when you have .

nosework electric junction boxes

northern new jersey metal fabrication

The earliest Craftsman Tool Boxes were typically made from durable steel and featured a classic red finish. They often had simple, yet robust, latches and handles. Identifying these early models can be challenging, but certain characteristics, such as the lack of modern amenities like drawer slides, can give you a clue about their vintage.

cnc machine operation ppt|cnc machine tools ppt