metallic transistor fabrication Substrate must be tied to GND, n-well to VDD Metal to lightly-doped semiconductor forms poor connection called Schottky Diode Use heavily doped well and substrate contacts / taps See more Westward’s wide selection allows you to customize your storage to fit your needs and space. Their heavy-duty tool boxes and chests, made of high quality steel, keep tools protected while providing smooth-gliding drawers and cabinets.

0 · two dimensional transistors

1 · silicon transistor fabrication

2 · semiconductor wafer fabrication

3 · semiconductor chip fabrication process

4 · fabrication of semiconductor devices

5 · cmos transistors

6 · cmos transistor fabrication

7 · 2d transistor array fabrication

CNC milling streamlines the process from prototyping to production with high-level precision, versatility, and efficiency for various applications. This article illuminates the top benefits that render CNC milling an indispensable tool in the engineer’s arsenal. 1. Precision and Consistency. CNC milling machines offer exceptional precision.

Introduction to the course How a transistor works CMOS transistors This module: CMOS Fabrication See more

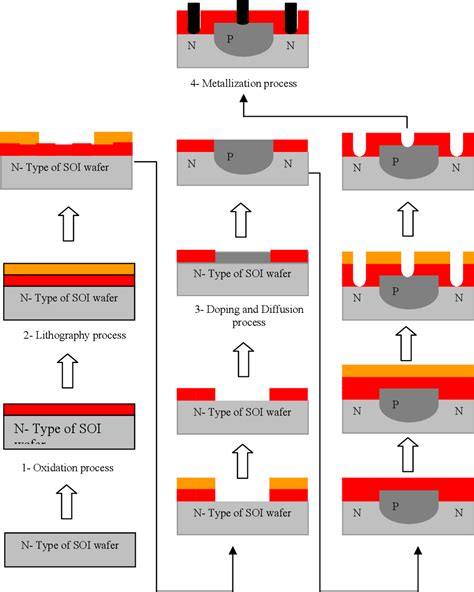

Typically use p-type substrate for nMOS transistors See moreCMOS transistors are fabricated on silicon wafers Lithography process has been the mainstream chip manufacturing process Similar to a printing press See Chris Mack's page for a . See moreSubstrate must be tied to GND, n-well to VDD Metal to lightly-doped semiconductor forms poor connection called Schottky Diode Use heavily doped well and substrate contacts / taps See moreSemiconductor device fabrication is the process used to manufacture semiconductor devices, typically integrated circuits (ICs) such as computer processors, microcontrollers, and memory chips (such as RAM and Flash memory). It is a multiple-step photolithographic and physico-chemical process (with steps such as thermal oxidation, thin-film deposition, ion-implantation, etching) durin.

In the fabrication of metallic nanotransistors, an electron beam lithography process has been developed to fabricate structures at the sub 30 nm scale using silver nanowires on .

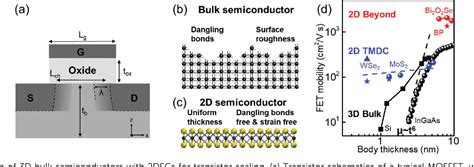

two dimensional transistors

silicon transistor fabrication

By transforming polycrystalline 1T’-MoTe 2 to 2H polymorph via abnormal grain growth, we fabricated 4-inch 2H-MoTe 2 wafers with ultra-large single-crystalline domains and . Here, we demonstrate a layer-by-layer transfer process of large-scale indium gallium zinc oxide (IGZO) semiconductor arrays and metal electrodes, and realize large-scale .fabrication steps. The one dimensional structure of metallic transistors allows the use of nanoimprint technology in terms of rapid and economical fabrications. Two types of metallic .Metallic nanotransistors are transistor structures made from a single layer of metal with dimensions in the sub 30nm scale. The primary advantages of a metallic transistor over .

The metallic SET transistors fabrication within the chip interconnect layers using CMOS back-end-of-line (BEOL)-compatible processing is shown in Parekh . It describes .This paper details the design and fabrication techniques of metallic nanotransistors. The limiting issues for writing sub30nm structures using EBL such as the charging effect of insulating .The single pass line exposure technique in electron beam lithography has been employed to define patterns of transistor structure as small as 20.2nm dimensions. This paper details the .

“A 32nm SoC Platform Technology with 2nd Generation High -k/Metal Gate Transistors Optimized for •Ultra Low Power, High Performance, and High Density Product Applications”, IEDM, Dec 2009. M1Semiconductor device fabrication is the process used to manufacture semiconductor devices, typically integrated circuits (ICs) such as computer processors, microcontrollers, and memory chips (such as RAM and Flash memory).

semiconductor wafer fabrication

In the fabrication of metallic nanotransistors, an electron beam lithography process has been developed to fabricate structures at the sub 30 nm scale using silver nanowires on Si 3 N 4 substrate. By transforming polycrystalline 1T’-MoTe 2 to 2H polymorph via abnormal grain growth, we fabricated 4-inch 2H-MoTe 2 wafers with ultra-large single-crystalline domains and spatially-controlled.

Here, we demonstrate a layer-by-layer transfer process of large-scale indium gallium zinc oxide (IGZO) semiconductor arrays and metal electrodes, and realize large-scale VFETs with ultra-short.fabrication steps. The one dimensional structure of metallic transistors allows the use of nanoimprint technology in terms of rapid and economical fabrications. Two types of metallic transistors have been explored and fabricated, the field-effect and the Y-branch metallic transistors. The metallic field-effect transistor operates similarly to theMetallic nanotransistors are transistor structures made from a single layer of metal with dimensions in the sub 30nm scale. The primary advantages of a metallic transistor over MOSFETs are its smaller dimensions and simple structures that require fewer fabrication steps. The metallic SET transistors fabrication within the chip interconnect layers using CMOS back-end-of-line (BEOL)-compatible processing is shown in Parekh . It describes fabrication of SET using nanodamascene process in detailed.

blanking process in sheet metal

This paper details the design and fabrication techniques of metallic nanotransistors. The limiting issues for writing sub30nm structures using EBL such as the charging effect of insulating materials, the proximity effects, and the single pass exposures are discussed.The single pass line exposure technique in electron beam lithography has been employed to define patterns of transistor structure as small as 20.2nm dimensions. This paper details the design and fabrication techniques of metallic nanotransistors.“A 32nm SoC Platform Technology with 2nd Generation High -k/Metal Gate Transistors Optimized for •Ultra Low Power, High Performance, and High Density Product Applications”, IEDM, Dec 2009. M1Semiconductor device fabrication is the process used to manufacture semiconductor devices, typically integrated circuits (ICs) such as computer processors, microcontrollers, and memory chips (such as RAM and Flash memory).

In the fabrication of metallic nanotransistors, an electron beam lithography process has been developed to fabricate structures at the sub 30 nm scale using silver nanowires on Si 3 N 4 substrate. By transforming polycrystalline 1T’-MoTe 2 to 2H polymorph via abnormal grain growth, we fabricated 4-inch 2H-MoTe 2 wafers with ultra-large single-crystalline domains and spatially-controlled. Here, we demonstrate a layer-by-layer transfer process of large-scale indium gallium zinc oxide (IGZO) semiconductor arrays and metal electrodes, and realize large-scale VFETs with ultra-short.

fabrication steps. The one dimensional structure of metallic transistors allows the use of nanoimprint technology in terms of rapid and economical fabrications. Two types of metallic transistors have been explored and fabricated, the field-effect and the Y-branch metallic transistors. The metallic field-effect transistor operates similarly to theMetallic nanotransistors are transistor structures made from a single layer of metal with dimensions in the sub 30nm scale. The primary advantages of a metallic transistor over MOSFETs are its smaller dimensions and simple structures that require fewer fabrication steps.

The metallic SET transistors fabrication within the chip interconnect layers using CMOS back-end-of-line (BEOL)-compatible processing is shown in Parekh . It describes fabrication of SET using nanodamascene process in detailed.This paper details the design and fabrication techniques of metallic nanotransistors. The limiting issues for writing sub30nm structures using EBL such as the charging effect of insulating materials, the proximity effects, and the single pass exposures are discussed.

semiconductor chip fabrication process

CNC machines can execute pre-programmed instructions precisely, ensuring consistent quality and minimizing the need for rework or scrap. Flexibility: CNC machines offer unparalleled flexibility in terms of production capabilities. They can easily switch between different machining operations, tooling configurations, and part geometries, making .Hard turning enables us to machine the precise final geometry of your custom parts after the heat treating process is complete. With heat treatment, the material properties of the machined part are optimized; however, the part’s geometry is .

metallic transistor fabrication|two dimensional transistors