all g code cnc machine In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete .

All good info, 1/8" (10ga) stock is plenty heavy enough, boxing strength is based on the rectangular tube shape formed, not the material thickness used. Before you start, .

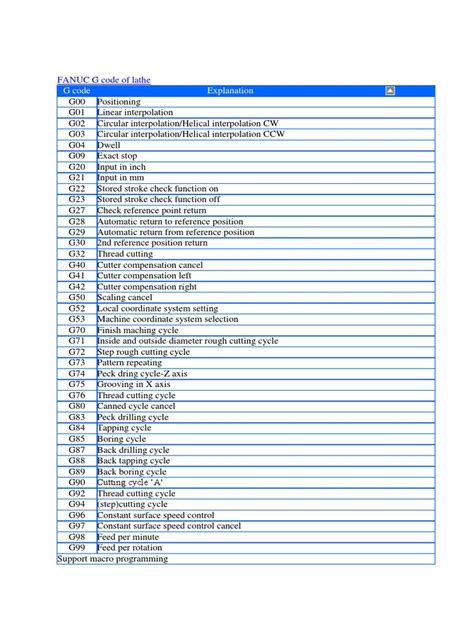

0 · list of fanuc g codes

1 · g codes all list

2 · g code for cnc milling

3 · free g codes for cnc

4 · complete g code list

5 · cnc turning g code list

6 · cnc router g code list

7 · cnc mill g code list

Learn about a junction box as it pertains to a residential home and its electrical wiring, plus DIY tips to install an electrical junction box.

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

cheapest make custom metal parts

CNC G-codes & M Codes for milling and turning with explanations, . Here is the list of all the Fanuc G Codes which are explained on . Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the .

G-code is a series of preparatory commands used to control CNC machines. It can be programmed manually or using software programs. The following is a list of G-codes used to program CNC mills and machining . In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete . Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections .

G-code is a programming language for CNC machines. It is generally called G instruction. We use this language to tell a machine what to do or how to do something. Using .

A CNC machinist will know how and when to use each code so that that part will run the most efficient. The program address “G” is a preparatory command. It prepares or .

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)Here is the list of all the Fanuc G Codes which are explained on HelmanCNC.com. Some of the Fanuc. CNC machines work by following the commands or instructions (G-codes / M-codes) which are given in Part Program. Here are G-codes for .I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machines

Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw . G-code is a series of preparatory commands used to control CNC machines. It can be programmed manually or using software programs. The following is a list of G-codes used to program CNC mills and machining centers. In a typical CNC program, G-codes and M-codes are used in combination.

In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete overview of its structure, commands, and applications. Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections with G20 and G21 for Inches and Millimeters, respectively. G-code is a programming language for CNC machines. It is generally called G instruction. We use this language to tell a machine what to do or how to do something. Using G code can realize fast positioning, anti circle interpolation, along circle interpolation, middle point arc interpolation, radius programming and jump machining. A CNC machinist will know how and when to use each code so that that part will run the most efficient. The program address “G” is a preparatory command. It prepares or presets the control system to use a certain mode or operation. Below is the list of G-codes that are used in most modern CNC Milling machines:

Every G code command sorted by how often they are used and organized by code type to make learning G code quick and simple.

CNC G-codes & M Codes for milling and turning with explanations, syntax and program examples. (Full list and guide)

list of fanuc g codes

Here is the list of all the Fanuc G Codes which are explained on HelmanCNC.com. Some of the Fanuc. CNC machines work by following the commands or instructions (G-codes / M-codes) which are given in Part Program. Here are G-codes for .I explore a large list of CNC G Codes and look at both their function and uses on both CNC lathes and CNC milling machines Explore G and M codes for CNC machining, including definitions, uses, key commands, and practical applications in modern manufacturing. CNC programming is at the heart of modern manufacturing, allowing machines to transform raw .

G-code is a series of preparatory commands used to control CNC machines. It can be programmed manually or using software programs. The following is a list of G-codes used to program CNC mills and machining centers. In a typical CNC program, G-codes and M-codes are used in combination. In computer numerical control (CNC) machining, G-code is the essential language used for precise communication between an operator and a machine. This guide seeks to demystify G-code by providing a complete overview of its structure, commands, and applications. Our exploration will include codes that are pivotal for operations such as G00 for Rapid Positioning, G01 for Linear Interpolation, through to specific functionalities like G17 for XY Plane Selection, and system selections with G20 and G21 for Inches and Millimeters, respectively. G-code is a programming language for CNC machines. It is generally called G instruction. We use this language to tell a machine what to do or how to do something. Using G code can realize fast positioning, anti circle interpolation, along circle interpolation, middle point arc interpolation, radius programming and jump machining.

g codes all list

Computer Numerical Control (CNC) machining is a manufacturing process in which pre-programmed computer software dictates the movement of factory tools and machinery. The process can be used to control a range of complex machinery, from grinders and lathes to mills and CNC routers.

all g code cnc machine|g code for cnc milling