inventor fold sheet metal I am trying to make a sheet metal part that has flanges folded down on one side and then folds running orthogonal to those flanges to make a somewhat curved have tunnel if . These are dark stainless steel and are still pretty high-contrast with the white cabinets. Whether black appliances and white cabinets are BFFs comes down to two things. 1. the OTHER finishes in your kitchen (countertop/backsplash/flooring) 2. perception (your personal opinion) Let’s start with your appliance’s surrounding finishes.

0 · inventor unfold sheet metal

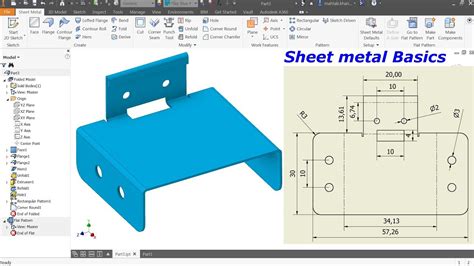

1 · inventor sheet metal folds

2 · inventor sheet metal defaults

3 · inventor sheet metal bend

4 · inventor change sheet metal thickness

5 · autodesk inventor sheet metal tutorial

6 · autocad fold sheet metal

7 · 07 autodesk inventor 2020 sheet metal

Pull the cables into the junction box. Most junction boxes have holes in their sides, called “knock outs.” Run each cable through one of the holes and attach them to the box with Romex or cable connectors. All of the cables should .

A fold on a sheet metal face forms about a straight sketched bend line that terminates at face edges. Unlike the bend, flange, contour flange, or hem features, which all add material to the design, the fold feature does not add material.

Inventor Sheet Metal Folds. Design & Motion.net. 7.24K subscribers. Subscribed. 101. 57K views 9 years ago. How to fold sheet metal faces within Autodesk Inventor.more. How to. About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright .

Using fold function in Sheet metal. I am trying to recreate a part that I already have a model to. The model is a solid form and I don't know how it was made. I am recreating it to make it thicker. I am trying to make a sheet metal part that has flanges folded down on one side and then folds running orthogonal to those flanges to make a somewhat curved have tunnel if .

The fold tool in sheet metal seems to want a new sketch for each fold line. Is there a way to fold this part using the existing construction lines in the sketch? Thank you. How to develop and fold sheet metal in Autodesk Inventor.Create a sheet metal part using the sheet metal template. The template uses your settings for material thickness, bend radius, and corner relief. You use sketch commands to create a .The Shape tab lets you specify the sheet metal faces and the bend settings to use when joining two or more faces. Faces are automatically trimmed or extended to create the bend. Single .

My 2018 Inventor doesn't want to let me fold sheet metal. I have tried to fold just a rectangle of sheet metal as well and it still would not work.

But I have the (3) flanges, 2 on the sides and a long one in the back. Then added corner seams between the long and sides to set and equal gap, but this pulls the corner style from the sheet metal defaults. With the hem . In a nutshell, you are using a derived component that does not allow the Inventor sheet metal module to see any bends. It exists as a solid body/block and there is no indication of where to unfold. Using Contour Flange . Hi all, I'm trying to model a sheet metal in Inventor Professional 2024 to the picture below, but find it impossible for a 0.5mm thick sheet metal to bend on a bent (at the four corners). It seems that the relief pattern due to .

I have a recurring problem. For example I draw a rectangle 150mm x 122mm: I extrude it to 0.7mm I create a 2D sketch and draw a simple line that ends on the edges of the rectangle. I go into "Sheet Metal" and click "fold" I choose "Bend Line" and then choose the line I drew in 2D sketch. i clic.

Inventor sheet metal fold with dimples Does anyone know how to do a sheet metal fold after dimples are placed onto a sheet metal flat? I am trying to duplicate what we are doing to our product and cannot get Inventor to maintain the dimples around the part. What happens is it actually "punches" the dimples out and leaves them on the original . The fold tool in sheet metal seems to want a new sketch for each fold line. Is there a way to fold this part using the existing construction lines in the sketch? Thank you. Autodesk Inventor Professional 2024 64-Bit Edition Build 343, 2024.3 Update - Date: Mon 3/18/2024 ; Autodesk Vault Professional 2024 Build 29.3.71.0 2024.3 Update Hi! To make Fold feature work more effectively, there are two conditions to watch out. First, the fold line should not pass or be located in the bend zone. If a fold line is in the bend zone, the fold feature will have to deform the bend zone, which is not a supported operation.Sheet metal rolls relative to a temporary plane at either end of the rolled material. You can unfold a folded sheet metal model that contains no flat face. You can refold a sheet metal model that has no flat faces and at least one rolled feature in the unfolded state. (You cannot refold unconsumed sketches that are created on unfolded rolled .

Good Morning, I've created a sheet metal part and have set my parameters. In using the fold feature, cannot create bend past 180 degrees. Radius is large enough (21") and sheet is long enough as there is still flat sheet after a 180 degree bend. How do you create bends past 180 degrees? Thanks for the help! ; Darren The fold tool in sheet metal seems to want a new sketch for each fold line. Is there a way to fold this part using the existing construction lines in the sketch? Thank you. Autodesk Inventor Professional 2024 64-Bit Edition Build 343, 2024.3 Update - Date: Mon 3/18/2024 ; Autodesk Vault Professional 2024 Build 29.3.71.0 2024.3 Update Have a question, for any sheetmetal workers. I am being told by our shop here that when part is shown in the flat view the Fab guy needs to see different style lines, for folds the go up or down. ie: If the Fold goes down the Fold line is show "Dashed" and if the Fold is going Up its shown as "Solid". A Few things, (1) I usually show the flat view on a second page, and on .

custom metal fabrication shop supplier

Hi All, I am working with the 30 day trial of Inventor 2016 to see if it would be a good fit for me. I manufacture with mainly 0.125" thick aluminum sheet. I use a CNC router to cut out parts and v groove engraving lines where all of the bends will occur for my enclosures. My first question is: Can I setup my folding lines on a sheet metal part to reflect a routed v groove . The fold tool in sheet metal seems to want a new sketch for each fold line. Is there a way to fold this part using the existing construction lines in the sketch? Thank you. Autodesk Inventor Professional 2024 64-Bit Edition Build 343, 2024.3 Update - Date: Mon 3/18/2024 ; Autodesk Vault Professional 2024 Build 29.3.71.0 2024.3 Update The fold tool in sheet metal seems to want a new sketch for each fold line. Is there a way to fold this part using the existing construction lines in the sketch? Thank you. Autodesk Inventor Professional 2024 64-Bit Edition Build 343, 2024.3 Update - Date: Mon 3/18/2024 ; Autodesk Vault Professional 2024 Build 29.3.71.0 2024.3 Update I'm trying to fold a piece of sheet metal with Countersinks. I can place the countersinks on the part before I fold the metal, but after the Fold, it looses the Countersinks but keep the thru hold information. If the Countersink Feature is Moused-over on the Model tree, you can still see the Countersinks along the Sketch. Can anyone out there help me?

The fold tool in sheet metal seems to want a new sketch for each fold line. Is there a way to fold this part using the existing construction lines in the sketch? Thank you. Autodesk Inventor Professional 2024 64-Bit Edition Build 343, 2024.3 Update - Date: Mon 3/18/2024 ; Autodesk Vault Professional 2024 Build 29.3.71.0 2024.3 Update First time using the sheet metal feature. I recreated my original part into a flat design (I would be interested in knowing if I could have unfolded my original design somehow, Unwrap gave nothing good). My part would be rolled around a 18mm cylinder. how can I fold/ roll it? I am unsure if Bend or Fold would achieve the shape I seek. I've built hundreds and hundreds of sheet metal parts and maybe used fold 2 times. (and that wasn't even a sheet metal part but a folded over tail on a membrane switch model or something like that) Inventor 2023 - Dell Precision 5570

Hello. I have unfolded a cone to a flat pattern in Autocad. Then, I have exported DWG to Inventor and got an sheet metal. But how can I fold this sheet of metal to a cone? I tried Bend and Fold options but it is no use. Please, ta a look at the attached file. Sergey Hi kaldor5, There is likely a better way to create your part than using the Fold tool, but if the Fold tool is used try adjusting the Bend Radius, the Fold Location, or the bend line location in the sketch.. Here you see that a Bend Radius of 0.07 works, but a Bend Radius of 0.08 extends the bend radius out, such that it runs past, and into the "wing" flange. I am using Inventor Professional 2011. How would I make a sheet metal fold that doesn't fold everything along that line? Something like creating a limit to where the fold will affect.

Also, for a better workflow for sheet metal design, try starting your part as a sheet metal part first and utilize contour flange. You'll still want to utilize best practices like fully constraining your sketch as the others have stated, but you can get the overall shape of your part pretty quickly: 1) start a 2D sketch and create your profile: This Autodesk Inventor tutorial displays the modeling process of a 'Mounting Bracket' model which is created by using Sheet Metal functionality of Autodesk I. Hello everyone, I want to create a sheet metal part in Inventor. Basically the part is a punched corrugated sheet that is folded again in an angle of 45° to the main fold. To create the corrrugated sheet I wrote a VBA skrip that creats a rectangular sheet metal, puts holes in it and folds it several times with a certain distance between the foldlines (ipt file is attached). How to check the K-factor of the sheet metal fold or bend, and to set the Sheet Metal properties and folding factors to transform the radii according to the material thickness in Inventor. To manage the K-factor in sheet metal parts: 1. Open sheet metal parts or use the Convert to Sheet Metal feature 2. Click the Sheet Metal Defaults 3. To edit or check the K .

Hi I've have not had that much experience of working with sheet metal. I have been asked to draw a simple bracket (see attached). I have used 2mm thk aluminium. I have been asked to supply the overall length of the flat pattern (which is no problem), and the bend allowance. How do I get this???? I've looked online and found a formula: bend . In part 22 of the Autodesk Inventor 101: The Basics series, we'll take a look at how to use the basic functionality of the sheet metal environment in Autodes.

inventor unfold sheet metal

Dave Whipple Sheet Metal Inc located at 1077 Cuyamaca St, El Cajon, CA 92020 - reviews, ratings, hours, phone number, directions, and more.

inventor fold sheet metal|inventor change sheet metal thickness