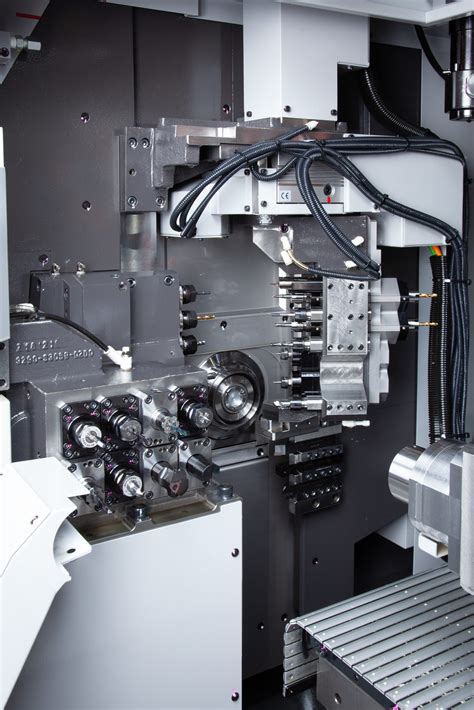

best swiss cnc machine Absolute Machine Tools is proud to offer Nexturn Swiss-style CNC lathes, which engineered to maximize accuracy and profitability in the production machining of complex precision parts. I decided to tidy up the wiring to my WC/Shower cloak room using a Wago Junction Box 224-112 and Wago connectors to replace the ceiling rose. The circuit to be:-Power In Switch 12W LED light 5W LED Light Vent Axia Svara Extract Fan The Earth wires and connectors are in a separate junction box.

0 · tsugami swiss machines

1 · swiss type cnc machine

2 · swiss machining vs lathe machine

3 · swiss cnc machine manufacturers

4 · swiss cnc machine for sale

5 · hanwha cnc swiss machines

6 · cnc swiss screw machines

7 · aerospace companies using swiss lathes

Walchem. 190949-10 Walchem Cable, 10 ft., to extend W400 contacting conductivity sensor, used with junction box

tsugami swiss machines

sheet metal applications pdf

The world of Swiss CNC machines is ever-evolving, driven by the relentless pursuit of precision, efficiency, and innovation. The top 10 manufacturers highlighted in this guide showcase the diverse range of offerings within the industry, catering to various requirements and industries. The best Programming/Communication S/W is Win-CNC which is 0 for 3 seats. With WinCNC, you can do magic. but it is only applicable to the Citizen. Following, if I were to . CNC Swiss machining is a cutting-edge precision manufacturing technique that has revolutionized the industry. In this comprehensive guide, we will explore the key components, working principles, applications, benefits, .Absolute Machine Tools is proud to offer Nexturn Swiss-style CNC lathes, which engineered to maximize accuracy and profitability in the production machining of complex precision parts.

Once seen as a specialty machine tool, the CNC Swiss-type is increasingly being used in shops that are full of more conventional CNC machines. For the newcomer to Swiss-type machining, here is what the .

Swiss lathes go popular in precision machining in recent years and many manufacturers choose CNC Swiss-type machines in the production. What is a Swiss lathe and how does Swiss lathe work? Get into the article and make .Swiss CNC Turning Machines. Our swiss-type machines are ideal for machining complex parts, working with difficult-to-machine materials, achieving fine surface finishes, and reducing tooling costs. CNC Swiss Machining with SyBridge. Swiss machining is a fast, accurate, and cost-effective manufacturing method that’s ideal for creating large quantities of small parts that require complex CNC turning. With Swiss-style machines and no experienced operators/programmers, that should be a deal-breaker. In the major 3 machine builders, I find Citizen can initially be the fastest setups because they've built-in good tool-setting modes. Star has very configurable Fanuc controls on most machines, ECAS-20 machines excepted.

A Swiss has nowhere near the rigidity of a lathe. Just look at the difference in the size of the bearings and their stance between a driven bushing and a lathe spindle. The Swiss does eliminate deflection in the bar since you are never cutting an unsupported length of stock. But it can never take the DOC at a high feed rate like a lathe can take.

To drudge up an old topic, what's the best CAM for 5 axis milling plus Swiss turning this year? Autodesk products are off the table. I'm used to Mastercam for milling, but they don't do Swiss well. I'd like to use the same package for both. I hear Topsolid is good? Maybe Esprit? Local support and training in or near Minneapolis would be . I have setup Brown & Sharpe (Ultra and G) and New Britain (model 52) screw machines and have a pretty well rounded background in simple screw machine work. I don't have any time with CAD/CAM software. All the CNC lathe programming I've done is simple 2 axis stuff, g-coded by hand (accurately.) 2 - Machine stability - machine does not heat up 3 - zero fire risk for overnight ops 4 - cost 5 - better tool life (10X more) Downsides: 1 - more maintenance 2 - risk of bearing or electrical damage. let me know if I am overlooking something silly. I don't really see a reason to use neat oil in a modern Swiss.

swiss type cnc machine

Swiss is not so diffident it just looks odd.Dont over think it.Most Swiss start out with the bar feed.This is done by letting the bar feeder push the material against the back of the part off tool (spindle stop).Then the collet will open and move to the start position part length plus 1/2 in(or tool width).Then a wight code M20 main and sub will synk at this point.There is often a m120 . The controls are a bit wonky, at times, but for the most part, everything is laid out neatly, the buttons have neat pictures on them, and the controls have built in help features. If you can run any other CNC machine well, you can learn a Citizen Swiss fairly quickly. Setups will take a bit longer, but not much, if you've setup other CNC machines. both have fairly large market shares globally in the swiss turning world. many shops have both, some only have one. from a control-machine integrator perspective the Citizen is awesome compared to Star. tool setting and programming is a breeze with Citizen machines, regardless if it is a fanuc or mitsubishi control in the backround. APSX-NANO CNC Swiss Lathe can machine ALUMINUM, STAINLESS STEEL, TITANIUM (Grade 2), BRONZE, BRASS, DELRIN (ACETAL), and other material with high precision on a desktop. It is a complete, ready-to-run system that includes the stand, embedded PC, keyboard, monitor, pendant, and a mist system and uses just a standard wall outlet for .

depends on type of part. often it is a piece of paper with part number, version number, program number name date of programmer at the top. then a sketch (sometimes done with a pencil ) or picture showing where zero is and some info on setup like size of parallels it sits on, shows vise jaws if overhanging on one side, etc. many have a tool list at least of tools not .

With Swiss-style machines and no experienced operators/programmers, that should be a deal-breaker. In the major 3 machine builders, I find Citizen can initially be the fastest setups because they've built-in good tool-setting modes. Star has very configurable Fanuc controls on most machines, ECAS-20 machines excepted. A Swiss has nowhere near the rigidity of a lathe. Just look at the difference in the size of the bearings and their stance between a driven bushing and a lathe spindle. The Swiss does eliminate deflection in the bar since you are never cutting an unsupported length of stock. But it can never take the DOC at a high feed rate like a lathe can take.

To drudge up an old topic, what's the best CAM for 5 axis milling plus Swiss turning this year? Autodesk products are off the table. I'm used to Mastercam for milling, but they don't do Swiss well. I'd like to use the same package for both. I hear Topsolid is good? Maybe Esprit? Local support and training in or near Minneapolis would be . I have setup Brown & Sharpe (Ultra and G) and New Britain (model 52) screw machines and have a pretty well rounded background in simple screw machine work. I don't have any time with CAD/CAM software. All the CNC lathe programming I've done is simple 2 axis stuff, g-coded by hand (accurately.) 2 - Machine stability - machine does not heat up 3 - zero fire risk for overnight ops 4 - cost 5 - better tool life (10X more) Downsides: 1 - more maintenance 2 - risk of bearing or electrical damage. let me know if I am overlooking something silly. I don't really see a reason to use neat oil in a modern Swiss. Swiss is not so diffident it just looks odd.Dont over think it.Most Swiss start out with the bar feed.This is done by letting the bar feeder push the material against the back of the part off tool (spindle stop).Then the collet will open and move to the start position part length plus 1/2 in(or tool width).Then a wight code M20 main and sub will synk at this point.There is often a m120 .

The controls are a bit wonky, at times, but for the most part, everything is laid out neatly, the buttons have neat pictures on them, and the controls have built in help features. If you can run any other CNC machine well, you can learn a Citizen Swiss fairly quickly. Setups will take a bit longer, but not much, if you've setup other CNC machines. both have fairly large market shares globally in the swiss turning world. many shops have both, some only have one. from a control-machine integrator perspective the Citizen is awesome compared to Star. tool setting and programming is a breeze with Citizen machines, regardless if it is a fanuc or mitsubishi control in the backround.

APSX-NANO CNC Swiss Lathe can machine ALUMINUM, STAINLESS STEEL, TITANIUM (Grade 2), BRONZE, BRASS, DELRIN (ACETAL), and other material with high precision on a desktop. It is a complete, ready-to-run system that includes the stand, embedded PC, keyboard, monitor, pendant, and a mist system and uses just a standard wall outlet for .

The WAGOBOX ® Light junction box is for use with our 224, 260 and 294 Series connectors. WAGOBOX ® LIGHT Suitable for lighting applications using WAGO's 224 series.

best swiss cnc machine|cnc swiss screw machines