cnc machine seminar ppt The document also covers the basic programming and operation of CNC . Precision CNC Machining manufacturer for global Aerospace, Power Generation and Defense industries. AS9100 Certified Ace Precision Corporation Jet Engine components, Engineered .

0 · cnc machine tools ppt

1 · cnc machine ppt template

2 · cnc machine ppt download

3 · cnc machine maintenance ppt

4 · cnc lathe machine working ppt

5 · cnc lathe machine ppt download

6 · cnc drilling machine pdf

7 · basics of cnc machine ppt

$24.95

* The document presents information about computer numerical control (CNC) machines, including a brief history, how they work, common elements and programming. * .The document also covers the basic programming and operation of CNC .

This presentation summarizes the key characteristics of CNC machines. It .Computer Numerical Control (CNC) Machining is the process through which .

The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions. Advantages of CNC . This presentation summarizes the key characteristics of CNC machines. It describes how CNC machines are automated machine tools controlled by programmed commands stored on a computer. The history of .CNC (Computer Numerical Control) Machine: The signals from the interface control the motors on the CNC machine. The signals determine the way the vice moves. The vice moves in three . * The document presents information about computer numerical control (CNC) machines, including a brief history, how they work, common elements and programming. * CNC machines operate automatically according to programmed codes and have precision, consistency and reduced human errors compared to manual machines.

The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions. Advantages of CNC include easier programming and reducing human errors, while challenges include high setup costs and requiring computer and programming knowledge.

This presentation summarizes the key characteristics of CNC machines. It describes how CNC machines are automated machine tools controlled by programmed commands stored on a computer. The history of CNC is outlined from its origins in the 1950s to become widely used today.

CNC (Computer Numerical Control) Machine: The signals from the interface control the motors on the CNC machine. The signals determine the way the vice moves. The vice moves in three directions X, Y and Z. (Horizontally, vertically and depth).This document summarizes a seminar presentation on CNC machines. It discusses the history of CNC, parts of CNC machines, types of CNC machines like lathes and milling machines. It also covers CNC programming basics including coordinate systems, G and M codes, and common turning operations.CNC machines have been widely adopted across industries like automotive, aerospace, machinery, and more to enable higher production rates and reduce costs through automated and repeatable machining.Overview We’ll first learn about axis systems. Then we’ll investigate how the machines understand where to move, and the kinds of moves they can make getting there. Machining and CNC Technology by McGraw-Hill Higher Education

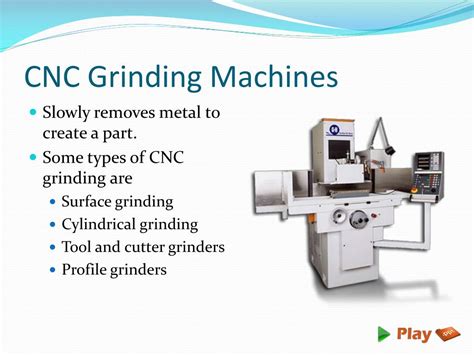

CNC Machines Seminar and PPT with PDF Report: Introduction, History, Why Use CNC Machines, Use of Typical CNC Machines, Parts, Advantages, Disadvantages. Computer Numerical Control (CNC) Machining is the process through which computers control machine-based processes in manufacturing. The kinds of machines controlled include lathes, mills, routers and grinders – all used for .Introduction CNC milling machines perform same functions as manual, and creates arcs, contours and 3D surfaces FIGURE CNC milling machines can produce complex part surfaces that would be virtually impossible to produce with manual milling machines. * The document presents information about computer numerical control (CNC) machines, including a brief history, how they work, common elements and programming. * CNC machines operate automatically according to programmed codes and have precision, consistency and reduced human errors compared to manual machines.

The document also covers the basic programming and operation of CNC machines using G and M codes to control axes movement, feed rates, spindle speeds, tool changes, and other functions. Advantages of CNC include easier programming and reducing human errors, while challenges include high setup costs and requiring computer and programming knowledge. This presentation summarizes the key characteristics of CNC machines. It describes how CNC machines are automated machine tools controlled by programmed commands stored on a computer. The history of CNC is outlined from its origins in the 1950s to become widely used today.CNC (Computer Numerical Control) Machine: The signals from the interface control the motors on the CNC machine. The signals determine the way the vice moves. The vice moves in three directions X, Y and Z. (Horizontally, vertically and depth).

This document summarizes a seminar presentation on CNC machines. It discusses the history of CNC, parts of CNC machines, types of CNC machines like lathes and milling machines. It also covers CNC programming basics including coordinate systems, G and M codes, and common turning operations.CNC machines have been widely adopted across industries like automotive, aerospace, machinery, and more to enable higher production rates and reduce costs through automated and repeatable machining.Overview We’ll first learn about axis systems. Then we’ll investigate how the machines understand where to move, and the kinds of moves they can make getting there. Machining and CNC Technology by McGraw-Hill Higher Education

CNC Machines Seminar and PPT with PDF Report: Introduction, History, Why Use CNC Machines, Use of Typical CNC Machines, Parts, Advantages, Disadvantages. Computer Numerical Control (CNC) Machining is the process through which computers control machine-based processes in manufacturing. The kinds of machines controlled include lathes, mills, routers and grinders – all used for .

cnc machine tools ppt

cnc machine ppt template

cnc machine ppt download

cnc machine maintenance ppt

cnc lathe machine working ppt

Buy Straight Metal Braces for Wood - 10-Pack Black Flat Mending Plate, 6 Inches Heavy Duty Fixing Corner Brace for Farmhouse Outdoor Woodworking, Length 6 Inches, Width 1½ Inches, Thickness 4mm - Black: Brackets - Amazon.com FREE DELIVERY possible on eligible purchases

cnc machine seminar ppt|cnc lathe machine ppt download