24 gauge metal sheet bending To bend sheet metals into accurate, clean, and professional-looking bends, the metal structure requires going through multiple bending processes depending on the weight, tensile strength, and other properties of the metal . Rotometals is now offering more accessories to help you with your zinc .

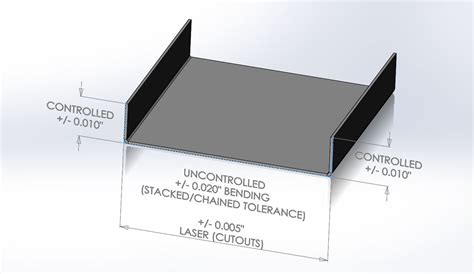

0 · sheet metal bending dimensions

1 · sheet metal bending angle chart

2 · sheet metal bend size

3 · sheet metal bend chart

4 · how to bend 24 gauge metal

5 · bending sheet metal tool

6 · bending sheet metal

7 · 24 gauge sheet metal bend

Explore Zurn's Z1 product family, offering a comprehensive range of innovative plumbing solutions. From commercial plumbing systems to sustainable water management, Zurn's Z1 series sets the standard for excellence.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake. See more

metal awnings for house

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending .Commonly known as “aviation snips” or “tinsnips,” these scissor-like tools are great for cutting soft sheet metals such as tin, aluminum, brass, and thin-gauge (24 gauge or thinner) steel. .Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are .

To bend sheet metals into accurate, clean, and professional-looking bends, the metal structure requires going through multiple bending processes depending on the weight, tensile strength, and other properties of the metal .Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make . Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.

This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.

Commonly known as “aviation snips” or “tinsnips,” these scissor-like tools are great for cutting soft sheet metals such as tin, aluminum, brass, and thin-gauge (24 gauge or thinner) steel. Depending on the cut shape, you’ll use left-cut, right-cut, or straight snips, typically indicated by the handle color: red for left, green for .

Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack. To bend sheet metals into accurate, clean, and professional-looking bends, the metal structure requires going through multiple bending processes depending on the weight, tensile strength, and other properties of the metal structure.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend.

Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.In air bending, the punch pushes on the sheet metal that is resting on the die's opening. We usually use a press brake for V bending because the sheet metal does not touch the bottom of the die. (A press brake is a simple machine used in sheet metal bending. It holds the sheet metal in place so the punch and die can bend it into the shape we want.)

An overview of minimum bend radii and bend orientation for sheet metal bending. Learn about how you can make better bent sheet metal parts.In this comprehensive guide, we delve into the intricate processes of Sheet Metal Bending, the vital role of Press Brakes, and the transformative impact they have in industries ranging from automotive to aerospace. Bending sheet metal by hand is a manageable task if the piece of sheet metal is small and thin enough to handle. Learn how to bend sheet metal so you can complete home and hobby projects easily without using a sheet metal brake.This Komaspec guide provides an overview of the main sheet metal bending processes, the advantages and disadvantages of each, basic design considerations with sheet metal bending and material selection information.

Commonly known as “aviation snips” or “tinsnips,” these scissor-like tools are great for cutting soft sheet metals such as tin, aluminum, brass, and thin-gauge (24 gauge or thinner) steel. Depending on the cut shape, you’ll use left-cut, right-cut, or straight snips, typically indicated by the handle color: red for left, green for .

Here are a few tips that will let you make accurate, clean, and professional-looking bends when you’re working with sheet metal. Some materials are more malleable than others. That means that some will bend, whereas others will weaken and crack.

sheet metal bending dimensions

To bend sheet metals into accurate, clean, and professional-looking bends, the metal structure requires going through multiple bending processes depending on the weight, tensile strength, and other properties of the metal structure.Bending sheet metal is a meticulous process. It involves a series of steps, starting from picking the correct type of metal, marking the bend lines, securing the metal on a bending brake, and finally applying the right amount of pressure to make the bend. Finding the minimum bend radius for steel or aluminum plate requires a little research. Learn how to bend metal and about bending steel plate and aluminum.

In air bending, the punch pushes on the sheet metal that is resting on the die's opening. We usually use a press brake for V bending because the sheet metal does not touch the bottom of the die. (A press brake is a simple machine used in sheet metal bending. It holds the sheet metal in place so the punch and die can bend it into the shape we want.) An overview of minimum bend radii and bend orientation for sheet metal bending. Learn about how you can make better bent sheet metal parts.

sheet metal bending angle chart

Zinus 4 Inch Low Profile Metal Box Spring with Wood Slats King. FREE SHIPPING ON ORDERS OVER $50. USD USD $ Home . Zinus 4 Inch Low Profile Metal Box Spring with Wood Slats King SEE ALL. BACK. At Fansideac, we never settle. We have an always testing, ‘always in beta’ philosophy, constantly improving to make it all just that bit better .

24 gauge metal sheet bending|sheet metal bend size