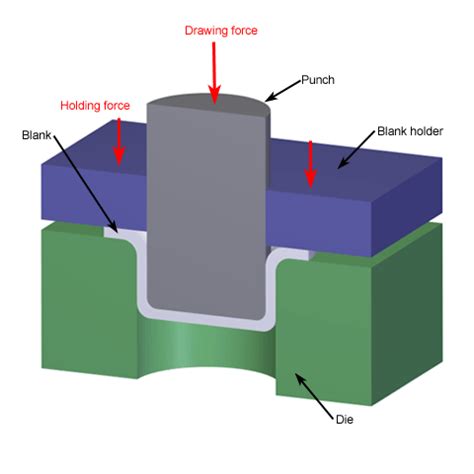

deep drawing sheet metal forming Deep drawing is a stamping and forming process in which a flat sheet is formed into an open hollow part through a concave die under pressure of a convex die. In all types of . This Two Drawer Metal File Cabinet features letter width drawers that are the perfect storage solution for professional offices or large home offices. This cabinet highlight a classic design and feature durable steel construction that can stand .

0 · sheet metal drawing techniques

1 · sheet metal drawing process

2 · metalforming drawing depth

3 · metalforming depth chart

4 · deep metal drawing

5 · deep drawing of sheet metal

6 · deep drawing metal parts

7 · deep drawing metal forming

Learn how to wire a 2 way switch in electrical circuit and understand the working mechanism of two-way switches. Get step-by-step instructions and diagrams for easy implementation.

These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels .

Deep drawing, at its essence, is a sheet metal forming process where the metal sheet is radially drawn into a forming die by the mechanical action of a punch. The depth of the formed part can be greater than its . Deep drawing is a stamping and forming process in which a flat sheet is formed into an open hollow part through a concave die under pressure of a convex die. In all types of .Deep drawing is a sheet metal forming process in which a flat blank is constrained by a blank holder while the central portion of the sheet is pushed into a die opening with a punch to draw . an their radius. Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains .

Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. [1] . It is thus a shape transformation . Sheet metal deep drawing is a metal forming operation. In this operation, sheet metal blank is subjected to drawing because of compressive and tensile forces. Sheet metal deep drawing technique. A deep-drawn component .

Let’s explore the step-by-step process of deep drawing an axial symmetrical round cup out of 0.062-inch material. The cup is 2 in. in diameter and 8 in. tall with no radius on top. To process a deep-drawn part, you must first .Deep drawing is fundamentally a metal sheet-forming technique that turns a flat metal sheet into a three-dimensional product. Imagine it as a more specialized version of metal stamping. To execute this technique, position a shaped metal .

These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations.

Deep drawing, at its essence, is a sheet metal forming process where the metal sheet is radially drawn into a forming die by the mechanical action of a punch. The depth of the formed part can be greater than its diameter, which is what differentiates deep drawing from other standard drawing processes. Deep drawing is a stamping and forming process in which a flat sheet is formed into an open hollow part through a concave die under pressure of a convex die. In all types of sheet metal components, deep drawing is often used for the processing of various cylindrical parts, hemispheres and parabolic heads of larger size or thicker material. Have you ever wondered how a flat sheet of metal can be transformed into a complex, hollow part? Deep drawing, a fascinating forming process, makes this possible. In this article, we’ll dive into the intricacies of deep drawing, .

Deep drawing is a sheet metal forming process in which a flat blank is constrained by a blank holder while the central portion of the sheet is pushed into a die opening with a punch to draw the metal into the desired shape without causing wrinkles or splits in the drawn part (Demeri, 2006). an their radius. Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains essentially the same from. start to finish. A deep drawn part can be recognized by its depth and its smooth, .Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. [1] . It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. Sheet metal deep drawing is a metal forming operation. In this operation, sheet metal blank is subjected to drawing because of compressive and tensile forces. Sheet metal deep drawing technique. A deep-drawn component has a depth equal to or more than the part radius when drawn. The process of sheet metal deep drawing involves multiple steps.

Let’s explore the step-by-step process of deep drawing an axial symmetrical round cup out of 0.062-inch material. The cup is 2 in. in diameter and 8 in. tall with no radius on top. To process a deep-drawn part, you must first know three basic things: the metal thickness, the metal type, and the blank size.Deep drawing is fundamentally a metal sheet-forming technique that turns a flat metal sheet into a three-dimensional product. Imagine it as a more specialized version of metal stamping. To execute this technique, position a shaped metal blank over a cavity. These deep-draw experts explain the deep-draw process, complete with tips and tricks to ensure proper, problem-free forming. Deep drawing of irregularly shaped panels constitutes one of the most complex metalforming operations. Deep drawing, at its essence, is a sheet metal forming process where the metal sheet is radially drawn into a forming die by the mechanical action of a punch. The depth of the formed part can be greater than its diameter, which is what differentiates deep drawing from other standard drawing processes.

Deep drawing is a stamping and forming process in which a flat sheet is formed into an open hollow part through a concave die under pressure of a convex die. In all types of sheet metal components, deep drawing is often used for the processing of various cylindrical parts, hemispheres and parabolic heads of larger size or thicker material. Have you ever wondered how a flat sheet of metal can be transformed into a complex, hollow part? Deep drawing, a fascinating forming process, makes this possible. In this article, we’ll dive into the intricacies of deep drawing, .

Deep drawing is a sheet metal forming process in which a flat blank is constrained by a blank holder while the central portion of the sheet is pushed into a die opening with a punch to draw the metal into the desired shape without causing wrinkles or splits in the drawn part (Demeri, 2006). an their radius. Deep drawn parts achieve their shape by drawing metal into a cavity rather than by stretching or thinning over a die, so the original sheet thickness remains essentially the same from. start to finish. A deep drawn part can be recognized by its depth and its smooth, .Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. [1] . It is thus a shape transformation process with material retention. The process is considered "deep" drawing when the depth of the drawn part exceeds its diameter. Sheet metal deep drawing is a metal forming operation. In this operation, sheet metal blank is subjected to drawing because of compressive and tensile forces. Sheet metal deep drawing technique. A deep-drawn component has a depth equal to or more than the part radius when drawn. The process of sheet metal deep drawing involves multiple steps.

Let’s explore the step-by-step process of deep drawing an axial symmetrical round cup out of 0.062-inch material. The cup is 2 in. in diameter and 8 in. tall with no radius on top. To process a deep-drawn part, you must first know three basic things: the metal thickness, the metal type, and the blank size.

sheet metal drawing techniques

machine zero in cnc

Adorned with 1,500 10-function color-changing micro LED lights featuring a twinkle function. Features 4,451 memory wire branch tips for effortless shaping an automatically lights up once poles are connected. Includes a folding metal tree stand, storage bag, remote control, .

deep drawing sheet metal forming|metalforming depth chart