sheet metal engineering drawing Drawing: Shapes-A myriad of shapes can be formed through multiple draws. Round shapes offer that greatest ease and economy in drawing. Then next best option is square with adequate . Our aluminium and heavy gauge steel ute and truck tool boxes are ideal for trade professionals and are protected from corrosion and the elements. Your tools will be water and dust resistant so your gear stays dry and protected.

0 · solidworks sheet metal part drawing

1 · solidworks sheet metal drawings

2 · simple sheet metal drawings

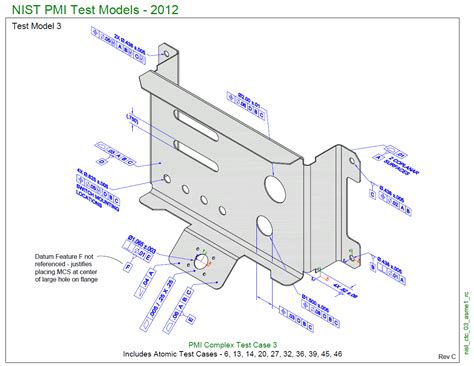

3 · sheet metal drawings with gd&t

4 · sheet metal drawing pdf download

5 · metal sheet riveted together drawing

6 · flat pattern sheet metal drawing

7 · basics of sheet metal design

Plus, you can also attach metal hooks to them for hanging tools – handy, right? All in all, they're a great design if you're looking for low-maintenance garden ideas for your greenhouse. 9.

Learn how to read and interpret 2D drawings for sheet metal fabrication, including dimensions, tolerances, material specifications, surface finishes, and fabrication processes. This guide covers the essential elements, .Drawing: Shapes-A myriad of shapes can be formed through multiple draws. Round shapes offer that greatest ease and economy in drawing. Then next best option is square with adequate . This article will provide a series of key sheet metal design and fabrication guidelines to help engineers and designers understand how to maximize the use of the characteristics of metal sheets, ensuring the feasibility .

best pc for cnc machine

See document 10-0005, Blah Drawing & Drafting Standards and Practices, for the proper setup of a sheet metal drawing. For door panels, front panels, interior panels, and racks see document .Sheet metal DFM - design guidelines for formed and punched parts. A first principles look at sheet metal design for manufacturability for experienced engineers. Sheet metal design skills are a crucial tool in any engineer’s .

What is Sheet Metal Drawing? Sheet Metal drawing process. Sheet metal drawing is not merely a process but an art, where flat metal sheets transform a three-dimensional shape by getting drawn over a die without . Sheet metal fabrication is a comprehensive cold-working process for thin metal sheets, typically less than 6 mm in thickness. This versatile manufacturing method encompasses a wide range of operations, including .This chapter explains how to create sheet metal drawings. Gauges for sheet metal are presented along with bend radii, flanges, tabs, reliefs, and flat patterns.

Unlock the secrets to precise fabrication with our expert guide on detailing sheet metal shop drawings. Enhance accuracy and efficiency in your projects. Read more! Eng-Tips is the largest engineering community on the Internet Intelligent Work Forums for Engineering Professionals. . Sheet Metal Gauge Callouts in Drawings 2. Thread starter wblanchard; Start date Mar 11, 2011; Status . Sheet metal fabricators know their sheet metal guages. They can read your numbers, and select the correct sheet from stock.

5. REQUIREMENTS FOR SHEET METAL PART DRAWINGS Sheet metal parts are typically created from material less than .250 inches thick, and are formed by folding the material at specific locations with a controlled bend radius. See document 10-0005, Blah Drawing & Drafting Standards and Practices , for the proper setup of a sheet metal drawing.Searching on various random sheet metal drawings I've seen, it's weird because it looks like everything is dimensions to 3 decimal places regardless of how critical the feature might be. . This sub is dedicated to the engineering and home .This chapter explains how to create sheet metal drawings. Gauges for sheet metal are presented along with bend radii, flanges, tabs, reliefs, and flat patterns. Sheet Metal Drawings. Figure 13-1 shows a 3D solid model of a sheet metal part and a dimensioned orthographic drawing of that part. The orthographic drawing was created from the 3D model. Sheet metal drawings serve as the foundation for sheet metal engineers to conduct sheet metal fabrication, aiding them in accurately understanding the structure and requirements of the part, thus enabling precise fabrication. Sheet metal drawing is a manufacturing process used to form flat sheet metal into a desired shape using a die and a .

Sheet Metal Drawings. Figure 13-1 shows a 3D solid model of a sheet metal part and a dimensioned orthographic drawing of that part. The orthographic drawing was created from the 3D model. The following sections explain how to create the 3D sheet metal drawing. We often hear from customers looking for ways to show Bend Lines on the drawing of sheet metal parts. There are several ways to get Sheet Metal Bend Lines to show (or not show) in a SOLIDWORKS drawing. This quick tutorial explains how. Where to Find Bend Lines. First, we need to know where the Bend Lines are stored/created/saved.

Reading an engineering drawing is crucial to be able to properly convey the design intent of a sheet metal part. Without this ability, designers and (most) fabricators won’t be able to work together to produce acceptable parts, and you could wind up with a pile of useless laser cut parts that don’t work.

For someone who may be taking that first step into having a sheet metal design created, here are the ESSENTIAL things that your drawing needs before sending . In the manufacturing process of heavy industrial equipment, the specific unit in the welding diagram is first manually redrawn and then the corresponding sheet metal parts are cut, which is inefficient. To this end, this paper proposes a U-net-based method for the segmentation and extraction of specific units in welding engineering drawings. This method enables the .For your drawing preparation, check out this article with our top tips for creating better sheet metal drawings as well as best practices for drawing reviews, so you can catch any last minute mistakes before your parts are released. All of your sheet metal DFM work will be wasted if you can’t communicate the requirements of your parts to .

Sep 6, 2022 - Explore kalla sravani's board "Sheet metal drawing" on Pinterest. See more ideas about sheet metal drawing, sheet metal, cad design. Pinterest. Today. Watch. Shop. Explore. . Engineering Drawing. Youtube Drawing. 3d Sketch. Isometric Drawing. 2d Drawing. Esercizio 64. Excavator Buckets. Teaching Geometry. Technical Drawings .CAD: computer-aided design, computer-aided drafting; cadmium [plating]: CAGE: Commercial and Government Entity [code]: A CAGE code is a unique identifier to label an entity (that is, a specific government agency or corporation at a specific site) that is a CDA, ODA, or MFR of the part defined by the drawing. One corporation can have many CAGE codes, as can one .Five Flute is a continuous design review platform that helps modern engineering teams share, review and improve their . Free Download Ultimate Guide to Sheet Metal Design. Learn how to design functional and easy to manufacture sheet metal parts regardless of your experience level or industry. . Design Reviews Drawing Reviews Customer .

If you’re into engineering and manufacturing, this is a must-read. We’ll cover everything from the basics to the nitty-gritty details, so buckle up and let’s get started! Introduction. . The image below shows the deep drawing . Deep drawing is a sheet metal forming process in which a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It is thus a shape transformation process with material retention. The .Sheet Metal ISSUES One of the biggest issues that our sheet metal customers face is a disconnect between design/engineering and manufacturing dept. Typically this means: Engineering/design may not be providing the right information to manufacturing. The finished part does not match the engineering drawing, creating the need for revisions.

Learn Sheet metal design, processes and practical design considerations along with Design projects. . Deep drawing process and Practice. Rolling, hydroforming, Stretch forming. . Mechanical engineering students learning product design and manufacturing processes; Designers who want to understand the sheet metal process to start making designs;

Construction Drawings Engineering HVAC Engineering Sheet Metal. Sheet Metal Shop Drawings. By MEP Academy Instructor. September 27, 2020. 0. 14578. Facebook. Twitter. Pinterest. Email. Chapter #7 – Sheet Metal Shop Drawings. Shop drawings should be created by someone in the company familiar with detailing. Detailing is the process of taking .Creo Sheet Metal Drawing. Solidworks Sheet Metal Drawings. Sheet Metal Design. Sheet Metal Drawing. . SolidWorks Sheet metal Exercise 129-Sketched Bend, Jog, Forming tool and Vent. Mahtabalam Khan. . Mechanical Engineering Design. Metal Bending.

Discover the top 5 free CAD software for sheet metal design, including FreeCAD, Onshape, and Fusion 360. Unleash your creativity with these powerful, easy-to-use programs that streamline your sheet metal projects. . It permits to draw 2D/3D models that can be used for engineering documentation, as well as the models that are used for CNC . In the manufacturing industry, the sheet metal process is common, and sheet metal parts are used in many different industries, including consumer products, appliances, aircraft, and the automotive and aerospace sectors. Sheet Metal Operations. Following are the 9 different types of sheet metal operations: Shearing Operations; Blanking OperationsDec 17, 2023 - Explore Justin Venkat's board "Sheet metal drawing" on Pinterest. See more ideas about sheet metal drawing, mechanical design, mechanical engineering design. Sheet metal drawing and pattern development by Dickason, A. (Alfred) Publication date 1983 Topics Mechanical drawing, Technical drawings Draftsmanship - For technicians Publisher London : Pitman Collection internetarchivebooks; inlibrary; printdisabled Contributor Internet Archive Language English

Eng-Tips is the largest engineering community on the Internet Intelligent Work Forums for Engineering Professionals. . My biggest problem with other people's sheet metal drawings is that they use drawing templates designed for machined parts, showing standard machining tolerances. Sheet metal shops can bend to around +/-.015" accuracy.Find and save ideas about sheet metal drawing on Pinterest. By utilizing sheet metal detailed drawings and advanced CAD-CAM technology, fabricators can compete more effectively and stay responsive to market needs. . Leading CAD Outsourcing Company offers solutions of Engineering CAD Services, Design Drafting & 3D Modeling. ← Back to blog. How Sheet Metal Detailed Drawings Address Concerns for .

solidworks sheet metal part drawing

Enjoy Warm & Healthy Meals --- This food warmer lunch box makes you enjoy .

sheet metal engineering drawing|solidworks sheet metal part drawing