cnc turning center parts DN Solutions boasts the industry's broadest range of CNC turning centers, ensuring a perfect fit for your specific needs. Whether you require horizontal or vertical configurations, DN Solutions' turning centers deliver unmatched . Whether it’s DXF files for 2D drawings, DWG files for intricate designs, STL files for 3D modeling, or the all-encompassing G-Code files, each file type plays a significant role in ensuring the CNC machine’s optimal performance and the creation of .

0 · turned parts manufacturer

1 · parts of cnc lathe machine

2 · high precision milling metal parts

3 · cnc turning services near me

4 · cnc turning machining parts factory

5 · cnc turning machining parts

6 · cnc turned parts manufacturer

7 · cnc machined parts buyers

Creative reuse of small boxes for office and utility supplies. Here I use both bottoms and lids of business card boxes to double the amount of storage containers in my desk drawer. Gift boxes, shipping boxes, and other .

CNC turning centers are essential for precision machining, offering high accuracy and efficiency in producing cylindrical parts. Understanding the components, operation, and .

The CNC Turning Center is one of the critical devices in today’s machining environment, as it allows the manufacture of complex parts with high levels of accuracy and productivity. This document addresses the parameters .

DN Solutions boasts the industry's broadest range of CNC turning centers, ensuring a perfect fit for your specific needs. Whether you require horizontal or vertical configurations, DN Solutions' turning centers deliver unmatched . Read on for an overview of the components, types, operations and applications of CNC turning centers. Turning Center Basics Lathes vs. Turning Centers: What’s the Difference? You’ve probably seen the terms . “A CNC turning center has milling capability, or a second spindle plus milling capability, and so it might have a Y-axis as well. We also call those Multi-Tasking Machines. That’s how I see turning centers: they offer more .Custom Turned Parts: Precision CNC Turning Services Get precision CNC turned parts for prototyping and production with RALLY, delivering top-quality metal and plastic components as quickly as 2-3 day. . These operations are performed .

turned parts manufacturer

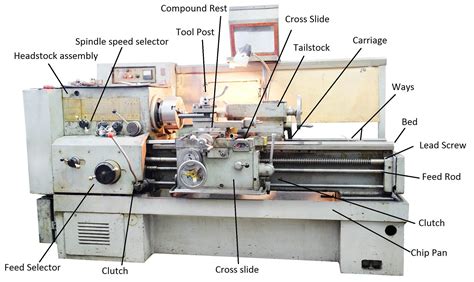

The types of parts created by a CNC lathe are often cylindrical, or symmetrical around an axis. What are the Parts of a CNC Lathe Machine? You can break CNC machines down into the following parts, and if . There are up .

Flatbed CNC turning center for heavy duty machining of large-diameter, long shaft workpieces Excellent chip removal mechanism, high-rigidity bed construction High rigidity spindle structure, ideal for large diameter workpieces of difficult machining material. Although CNC machining (computer numerical control) is a blanket term covering several types of automation–routers, EDM, plasma, etc.–CNC turning and CNC milling are the two most popular CNC machines.Both machining processes are essential, and, it’s safe to say, they could handle most of the work in a typical machine shop. As a rule of thumb, think of the CNC .

Description: Produced by Cam operated Lathe, CNC Lathe, Swiss-style Lathe, Machining Center. Characteristics: Customized by.The TC2 Turning Center is a compact CNC lathe for precision machining, offering fast setups, the latest ProtoTRAK control, and reliable performance for diverse materials. . Maintenance, Service & Parts List - 35006 (3.1MB) Software. ProtoTRAK RX CNC Offline Software (1 GB) ProtoTRAK RX CNC Software (1.1 GB) Top . Sitemap. One-Off & Small Lot .

parts of cnc lathe machine

Find the best quality and durable cnc turning parts, CNC Turning Parts, CNC parts,CNC center,CNC turning,SS fitting,Screw,Stainless steel,Stainless stell fitting,304 fitting,303 fitting,Gas fitting,phone fitting,car fitting,camera fitting,bolt,nuts,Brass fitting,plastic parts,here at cncturningpart.com. It's competitive in its high flexibility and long durability.

CNC Manual / Okuma / Okuma Parts Book / Okuma Turning Center LT15-MY Parts Book. Okuma Turning Center LT15-MY Parts Book. Views: 44286 . Continue with reading or go to download page. Read Download. Recommended. Lyndex-Nikken . Would there be a way and is it practical to machine, slowly, an off center diameter on the end of a part on a CNC Haas lathe? What I am planning has a diameter of about 5mm with a 4mm diameter only about 2mm long that is off center about .5mm, in aluminum or brass. The spindle would turn slowly with the X moving fast in relation. Chapter 3 CNC turning and machining centers - Download as a PDF or view online for free . (HMC):-It is used for cube shaped parts where tool access can be best achieved on the sides of the cube. Turning centre or Lathe is a type of Horizontal machining centre Prepared by: Prof. Rahul Thaker (ACET) . Combination Tools • If machining center .At RidgelineCNC, we boast cutting-edge CNC turning technology. Our Y-axis and live tooling-equipped lathes enable additional features such as milling, drilling, and tapping off the center line of the part. This streamlined process results in one-step completion, saving time and enhancing accuracy. Trust Ridgeline for all your CNC turning .

high precision milling metal parts

CNC Turning Centers. Swiss-Style Production Turning Machines. Vertical Machining Centers . and laser. Mazak provides products and solutions that can support a wide range of parts machining processes, such as high-speed and high-accuracy machines, various automation systems, and production support software and CNC equipment that support skill .Study with Quizlet and memorize flashcards containing terms like At the most basic level, a lathe is a machine that:, The materials that a lathe might be cutting can vary from wood and plastic, all the way to aluminum or hard steel., Regardless of whether a the cutting action of a lathe is controlled manually, by hand, or completely automatically by a computer, the job of the .

We urgently need *CNC TURNER CUM PROGRAMMER* at *Devson Presstech Pvt Ltd* Machine - 1200 mm length Controller- Fanuc Oi-TF Location - Delhi Mundka opposite metro pillar no 491 Sallary - 20 to 25k. CNC machining parts, turning-milling, five axis, machining center | We urgently need *CNC TURNER CUM PROGRAMMER* at *Devson Presstech Pvt Ltd*Introduction to Mazak Corporation's Products, CNC Turning Center HQR - Products. Products. Multi-Tasking Machines; 5-Axis Machining Centers; CNC Turning Centers; . By using a workpiece unloader instead of the auto parts .

What is CNC turning? CNC turning produces parts by mounting a blank on a rotating chuck and removing material using stationary cutting tools. This technology is ideal for manufacturing parts with symmetry along their center .

There are several key components to consider when working with a CNC turning center for your machining processes. CNC is considered an essential tool across numerous industries due to its: Precision – When utilizing CNC turning technology, the automation process can deliver the most precise, complex, and innovative designs. This allows .CNC turning centers have revolutionized the manufacturing industry, allowing for precise and efficient production of complex parts and components. Whether you're a small business owner or a seasoned operator, choosing the right CNC turning center can be daunting given the wide variety of brands, models, and features available on the market. Furthermore, CNC turning centers can easily fit with “Live tools,” incorporating milling, tapping, and drilling across a tuning profile. The automatic feeding of material and changing of tools within the programmed cycle ensures that CNC turning centers can produce more efficiently CNC turned parts than a CNC lathe turning center.Time to read: 6 min. CNC turning services offer a widespread technology for manufacturing cylindrical parts from various materials. Unlike CNC milling, CNC turning rotates the workpiece and introduces a stationary tool into the workpiece.Advanced CNC turning centers take this further by adding milling functionality to the machine to produce highly complex parts like .

Flatbed CNC turning center for heavy duty machining of large-diameter, long shaft workpieces Excellent chip removal mechanism, high-rigidity bed construction High rigidity spindle structure, ideal for large diameter workpieces of difficult machining material.Flatbed CNC turning center for heavy duty machining of large-diameter, long shaft workpieces Excellent chip removal mechanism, high-rigidity bed construction High rigidity spindle structure, ideal for large diameter workpieces of difficult machining material.A Turning Center for Every Shop. Haas Automation’s complete line of CNC turning centers is designed to meet the needs of modern machine shops – now and long into the future. . Dual-Spindle Turning More Parts, Fewer Setups. Multitasking is key to reducing setups and increasing part accuracy. Our dual-spindle, Y-axis lathes provide “done .In summary, the choice between a CNC machining center and a turning center should be guided by the specific requirements of your projects, including the types of operations needed, the complexity and volume of the parts, and the material characteristics. Understanding these key differences and capabilities will help ensure you select the right .

cnc turning services near me

Reference #32335, Cincinnati Avenger 250S CNC Horizontal Turning Center with Sub Spindle, S:, Acramatic 850SX CNC Control, LNS QL Servo S2 Auto Bar Feeder with Control Pendant, Main/Sub Spindle, Tool Eye, Parts Catcher, Maximum Swing Over Bed. 23.54", Maximum Machining Diameter. 10.55", Maximum Machining Length.Easy to understand CNC turning center/cnc lathe programming example for cnc machinists who work on cnc turning centers/cnc lathe machines. This cnc program. ≡ MENU. . Your cnc machine workshop mostly machine small and innovative parts, then why use behemoth cnc machines?. For small parts use small cnc machines, because using a small cnc .

cnc turning machining parts factory

cnc turning machining parts

MIG (Metal Inert Gas) welding is the most commonly used type of auto body repairs. The process of MIG welding involves continuously feeding the weld area with a wire (filler metal) along the weld seam.

cnc turning center parts|cnc turning services near me